3-14 SHB 28Z3 EN – Edition 2.0 * 28z3s312.fm

Maintenance

Use a suitable container to collect the fuel as it drains and dispose of it in an environmen-

tally friendly manner!

Filler inlet A for the fuel tank is located in the valve compartment, on the left in driving

direction.

Proceed as follows:

☞ Open filler inlet A

☞ Pump out the fuel with a suitable pump

➥ Collect the fuel in a suitable container

Stationary fuel pumps General

Only refuel from stationary fuel pumps. Fuel from barrels or cans is usually dirty.

Even the smallest particles of dirt can cause

• Increased engine wear

• Malfunctions in the fuel system and

• Reduced effectiveness of the fuel filters

Refuelling from barrels

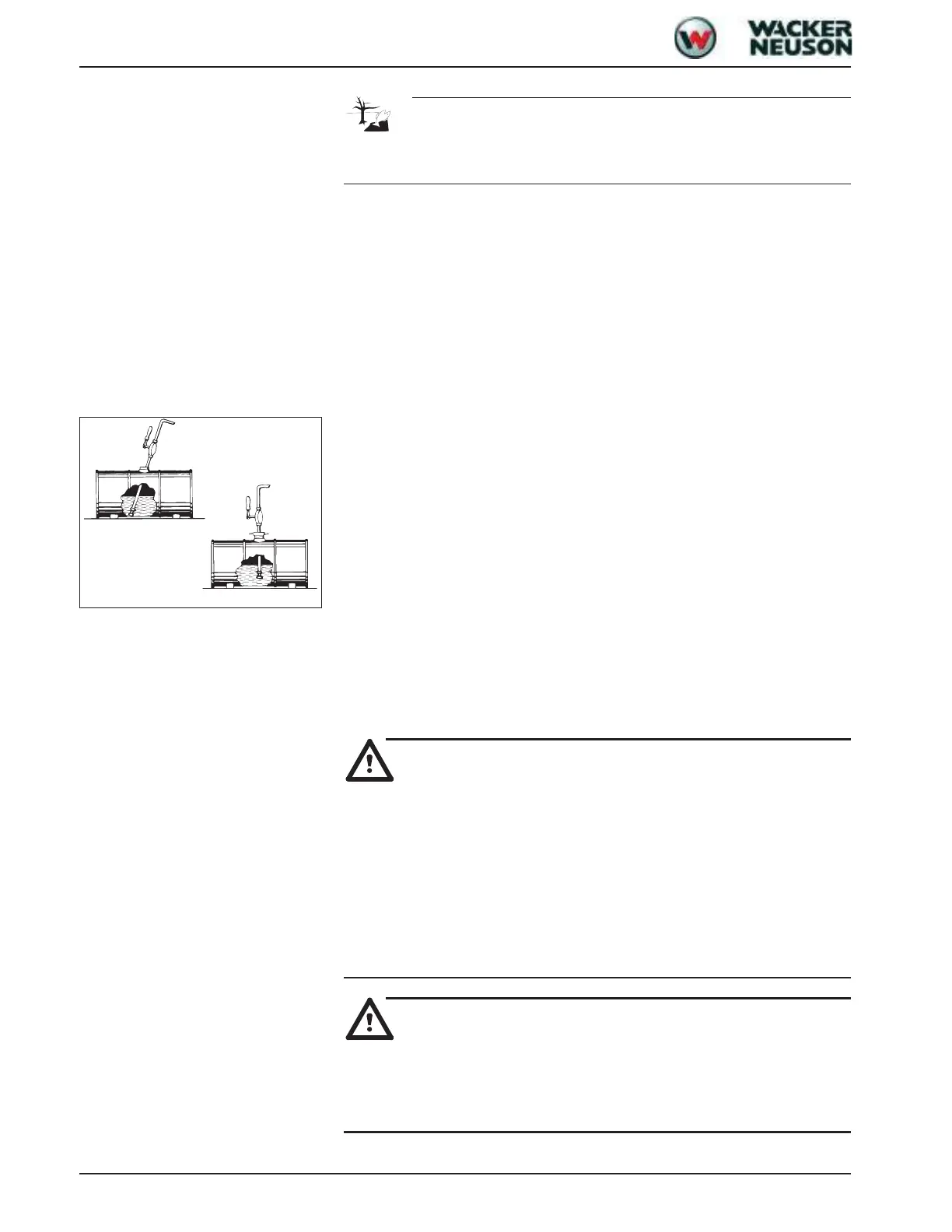

If refuelling from barrels cannot be avoided, note the following points (see fig. Fig. 3):

• Barrels must neither be rolled nor tilted before refuelling

• Protect the suction pipe opening of the barrel pump with a fine-mesh screen

• Immerse it down to a max. 15 cm (5.9”) above the floor of the barrel

• Only fill the tank using refuelling aids (funnels or filler pipes) with integral microfilter

• Keep all refuelling containers clean at all times

Diesel fuel specification

Use only high-grade fuels – see chapter 3.1 Fluids and lubricants on page 3-2

Bleeding the fuel system

Danger!

If the fuel, as it drains, comes into contact with hot engine parts, there is an

increased

Danger of burns!

☞ Work on the fuel system may be carried out only in an absolutely clean

environment!

☞ Bleed the fuel system only if the engine is cold!

☞ Filter elements and drained fuel must be disposed of correctly.

☞ Always wear protective equipment and safety glasses when working with

fuel.

Danger!

Danger of injury due to rotating parts!

☞ Before starting the engine, ensure that no-one is within danger area of the

engine/the machine!

☞ Start the engine only if the engine cover is closed!

Wrong

Right

Fig. 3: Refuelling from a barrel

Loading...

Loading...