3-50 SHB 28Z3 EN – Edition 2.0 * 28z3s314.fm

Maintenance

3.18 Tracks

• Track wear can vary according to work and ground conditions.

☞ We recommend checking track wear and tension once a day.

☞ Park the machine on firm and level ground to check and carry out maintenance.

Checking track tension

Danger!

Working under the machine is extremely dangerous if the tracks are off the

ground and if the machine is only supported by the attachment.

Caution, danger!

☞ Ensure that no-one is in the danger area!

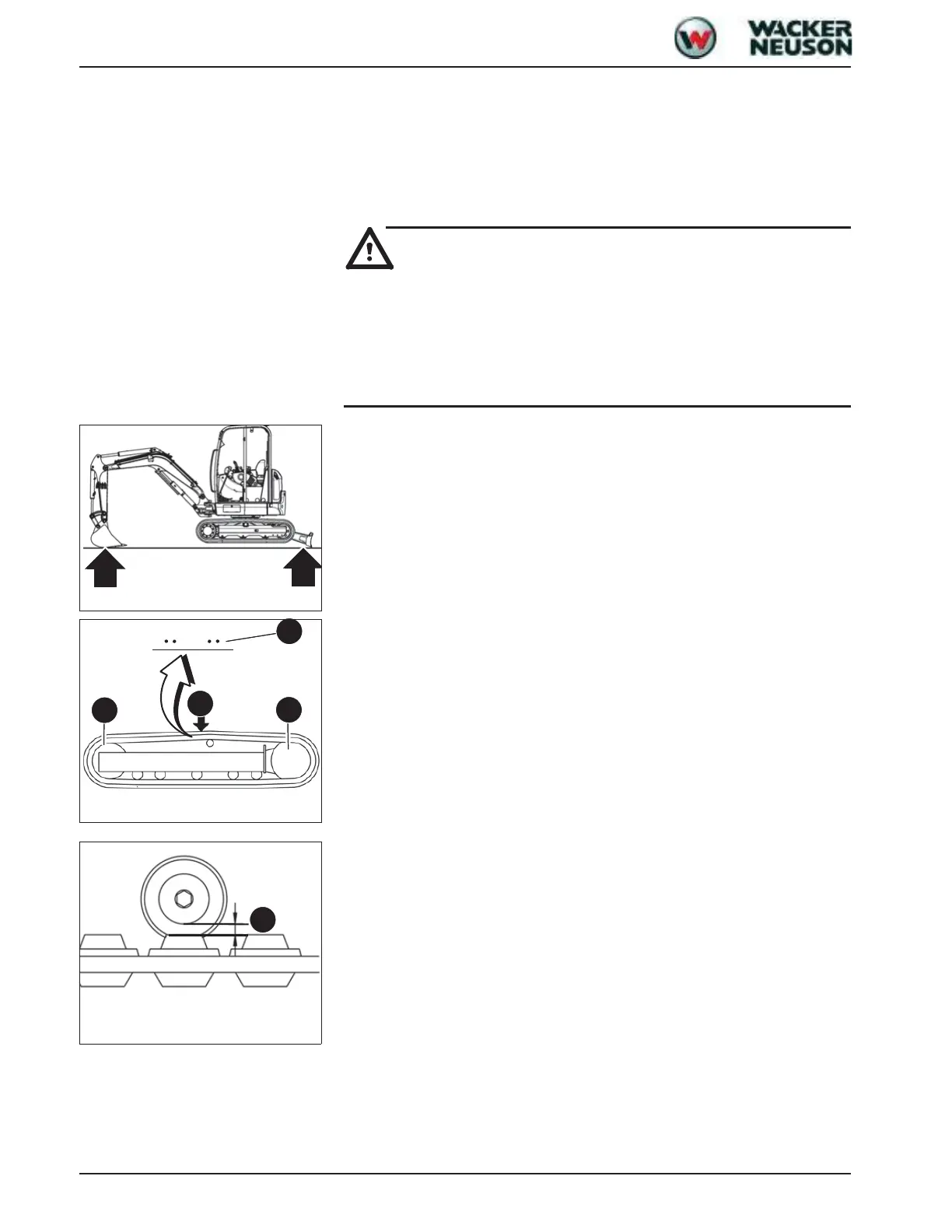

☞ Support the machine so as to allow the tracks to sag freely.

☞ Stop the machine on firm, level and horizontal ground

☞ Raise the machine evenly and horizontally

☞ Raise the machine by means of the boom and the stabiliser blade

☞ Slowly and carefully actuate the control levers

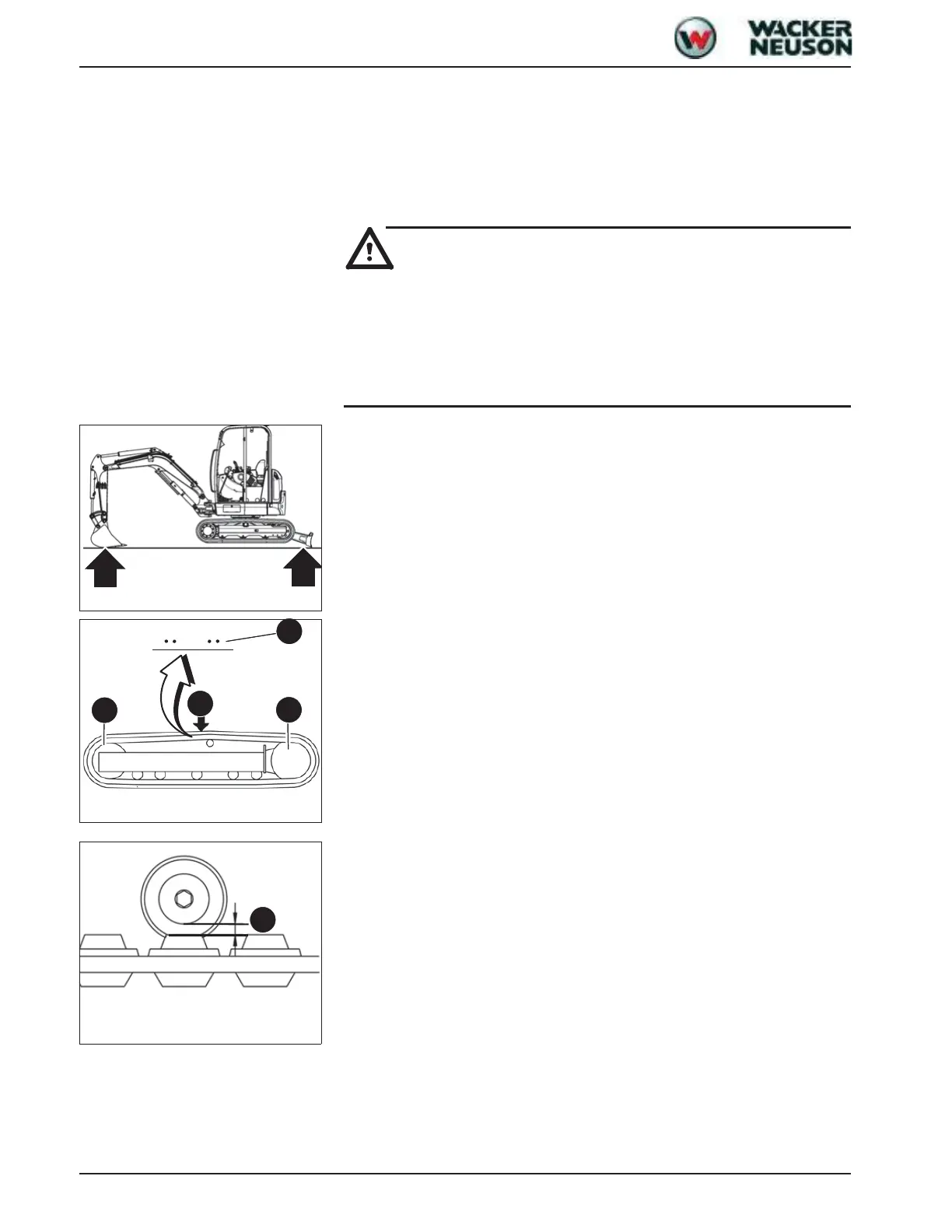

☞ The rubber track has a mark B as shown in Fig. 60

☞ Place the machine so that mark B of the rubber track is between the drive pinion C and

the track tension roller D

☞ Stop the engine

☞ Fold the control lever base up

☞ Remove the ignition key and carry it with you

• The play a between the sliding block's shoulder and the contact area of the second

support roller of the drive pinion is 20 – 25 mm (0.78 – 0.98”).

☞ If the tension of the steel or rubber track is not in accordance with the rated value,

adjust the tension as follows.

Fig. 59: Raising the machine

Fig. 60: Rubber track mark

B

D

C

8

B

Fig. 61: Measuring distance

a

Loading...

Loading...