SHB 28Z3 EN – Edition 2.0 * 28z3s410.fm 4-7

Engine

☞ Adjust the valve clearance by turning set screw B.

➥ The feeler gauge must slip between the valve cap and rocker arm with slight

resistance.

➥ Valve clearance: 0.15 – 0.25 mm (0.0059 – 0.0098”)

☞ Tighten locknut C while holding set screw B

➥ Lightly oil the surface between the valve tappet and the set screw

Notice!

The valve clearance tends to decrease slightly when the locknut C is tightened –

pay attention to this during adjustment

☞ Check the valve clearance again

☞ Repeat the procedure for each valve

☞ Place the valve cover gasket

☞ Mount the valve cover again

Lapping the intake and exhaust valves

To ensure an exact clearance, the intake and exhaust valves must be lapped every 2000

service hours

4.5 Tightening order for cylinder head bolts

Notice!

Always carry out work on the cylinder head on a cold engine!

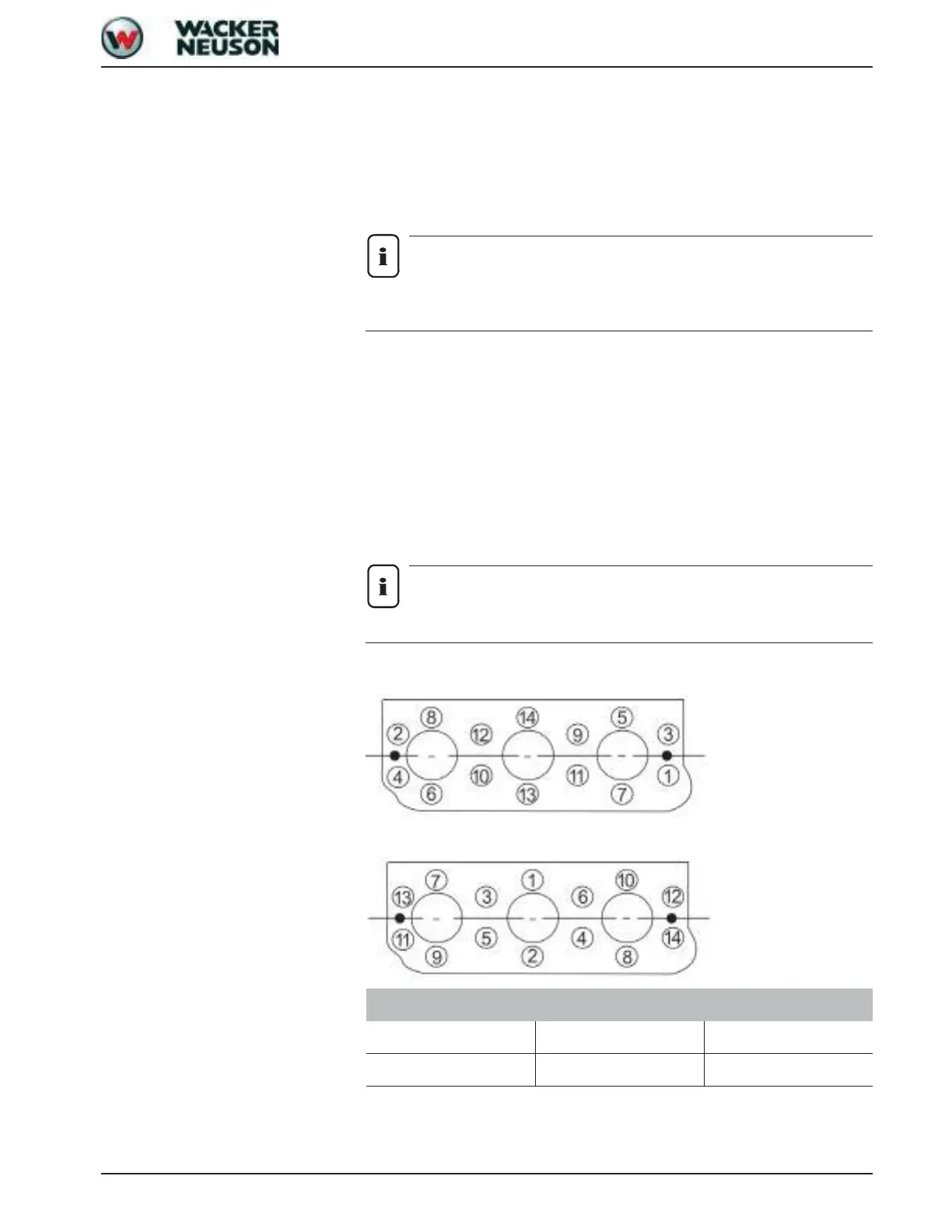

Order for removing the cylinder-head bolts:

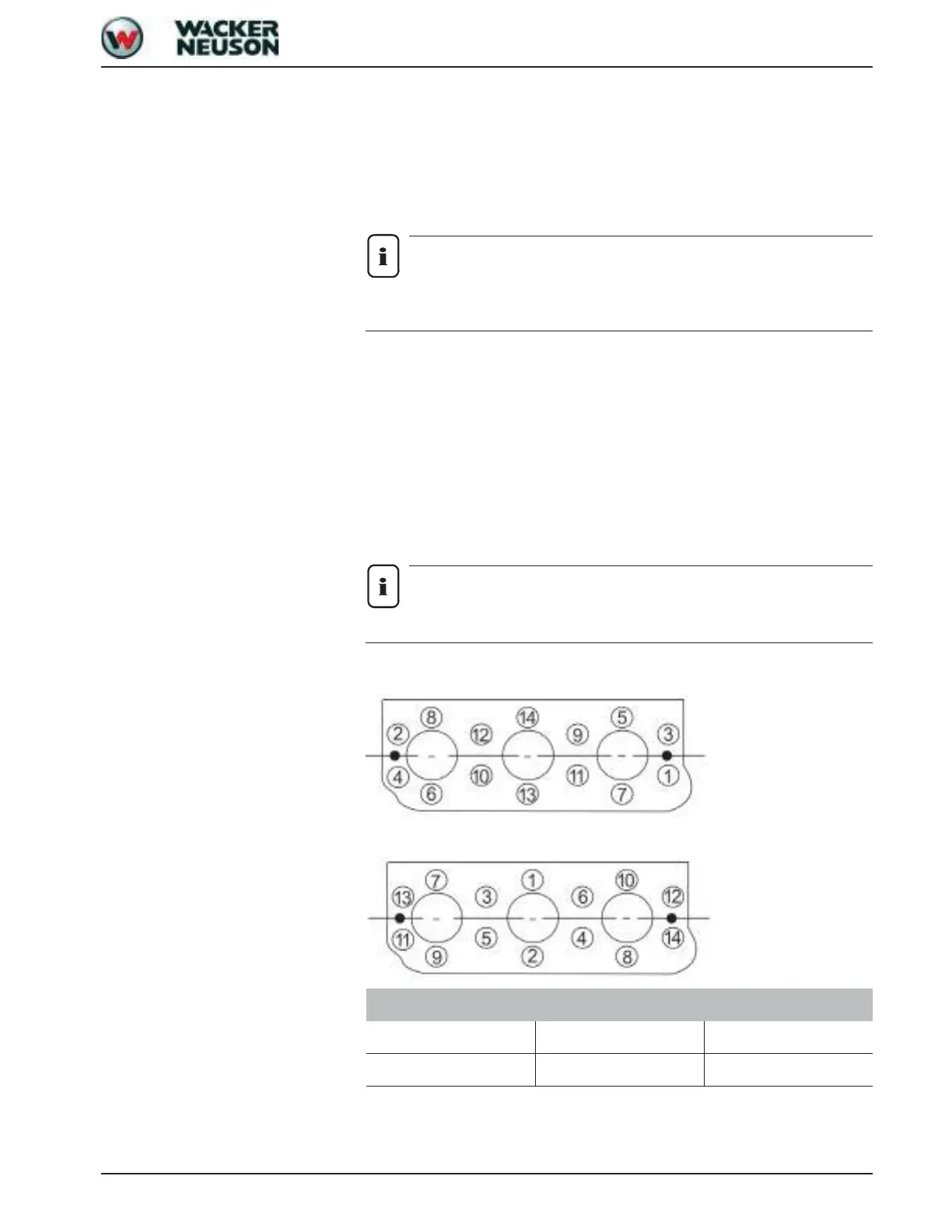

Order for mounting the cylinder-head bolts:

V-belt side

Tightening torques for cylinder-head bolts

1st position 26.9 – 28.9 Nm 19.8 – 21.3 lbs/ft

2nd position 53.9 – 57.9 Nm 39.8 – 42.7 lbs/ft

Loading...

Loading...