4-14 SHB 28Z3 EN – Edition 2.0 * 28z3s410.fm

Engine

Notice!

If a new or newly calibrated injection pump is fitted, at least 0.15 – 0.20 l (0.04 –

0.05 gal) of new, clean engine oil must be filled through the top rear plug of the

governor

☞ Bleeding the fuel system

☞ Start the engine and check for any fuel or engine oil leaks

4.10 Measuring and adjusting the engine speed

Measuring the engine speed

The engine speed can be quickly and simply determined with a tachometer

☞ Measurement on the crankshaft disc or on the ring gear

☞ A manual tachometer Fig. 18 can be obtained from a Wacker Neuson workshop

Notice!

The maximum engine speed is set and sealed by the manufacturer without the

pump and may not be modified!

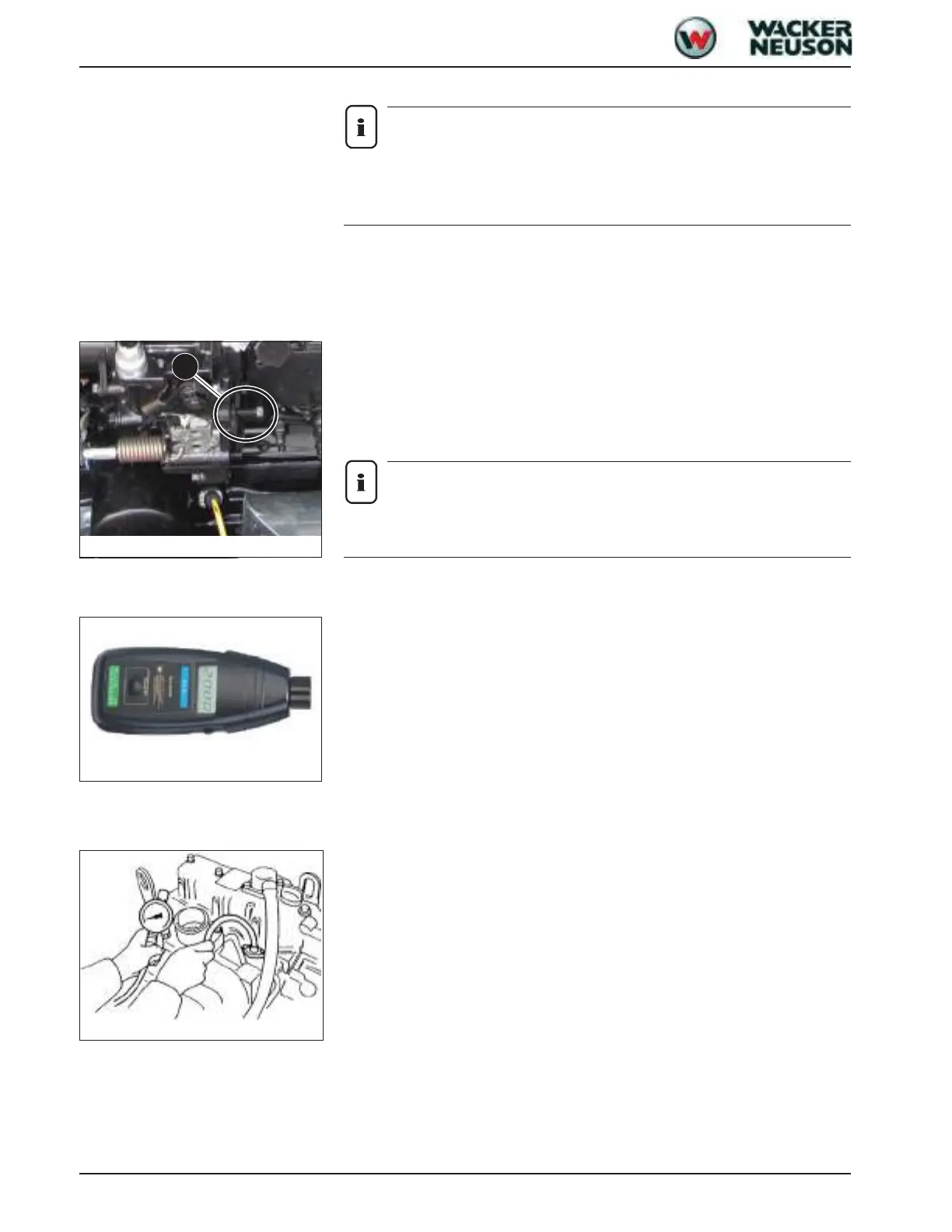

Adjusting engine speed

Only the idling speed can be adjusted

☞ Adjust engine speed without load!

☞ Run the diesel engine until it reaches operating temperature

☞ Check idling speed and maximum engine speed with all attachment functions in neutral

➥ Idling speed: 1300 +/- 25 rpm

➥ Max. engine speed: 2375 +/- 25 rpm

☞ In the event of deviation, correct the idling speed by means of the idling speed set

screw A

4.11 Compression

☞ Clean the engine

☞ Run the diesel engine until it reaches operating temperature

☞ Remove the injection lines and the injection nozzles

☞ Set the injection pump to zero delivery

➥ Remove the connector for the cutoff solenoid

☞ Turn the engine before attaching the compression gauge

➥ The remaining fuel is ejected

☞ Attach the compression gauge to the respective cylinder with a sealing ring

☞ Turn the diesel engine with the starter and read off the pressure on the pressure gauge,

repeat until the reading is stable

➥ Specified value: 34.3 +/- 1 bar (498 psi +/- 15) at 250 rpm

➥ Threshold value: 27.5 +/- 1 bar (399 psi +/- 15) at 250 rpm

Fig. 18: Adjusting engine speed

A

Fig. 19: Manual tachometer

Fig. 20: Compression

Loading...

Loading...