4-12 SHB 28Z3 EN – Edition 2.0 * 28z3s410.fm

Engine

4.9 Removing and installing the injection pump

Removing the injection pump

☞ Mark the original position of the injection pump on the pump and gear casing – see

Mark on pump housing on page 4-11

☞ Shut off the fuel supply (fuel cock), clean the area of the injection pump and have a

container ready to collect any leaked fuel

☞ Remove the fuel injection lines, fuel and leak oil lines

➥ Close any open connections to prevent soiling and to minimise leakage

☞ Unhook the Bowden cable on the injection pump and remove the cutoff solenoid

Remove cover A of the injection pump on the gear casing

➥ Cover A is mounted with sealant, therefore separate the cover from the gear casing

with a scraper

☞ Mark position E of injection pump gear C in relation to gear position B

☞ After marking, do not turn the crankshaft

➥ Tighten the screw of the pulley with a long spanner to fix the crankshaft in place

☞ Slacken lock nut D of gear C and unscrew until the shaft end of the injection pump

☞ Use an extractor to pull off/slacken gear C on the conical shaft

☞ Loosen lock nut D completely and remove it from the gear casing with the spring

washer and gear C

Notice!

Gear C of the injection pump can be removed from the gear casing. We recom-

mend, however, leaving gear C meshed with the gear B in the gear casing.

Notice!

Do not slacken screws F of the gear of the injection pump, as these specify the

precision setting of the fuel injection pump set by the manufacturer!

➥ It is very difficult or even impossible to subsequently set the correct

injection time

☞ Remove the fuel injection pump

➥ To this purpose unscrew the three fastening screws of the injection pump

Notice!

After removing the injection pump, do not turn the crankshaft anymore

Fig. 13: Gear casing cover

A

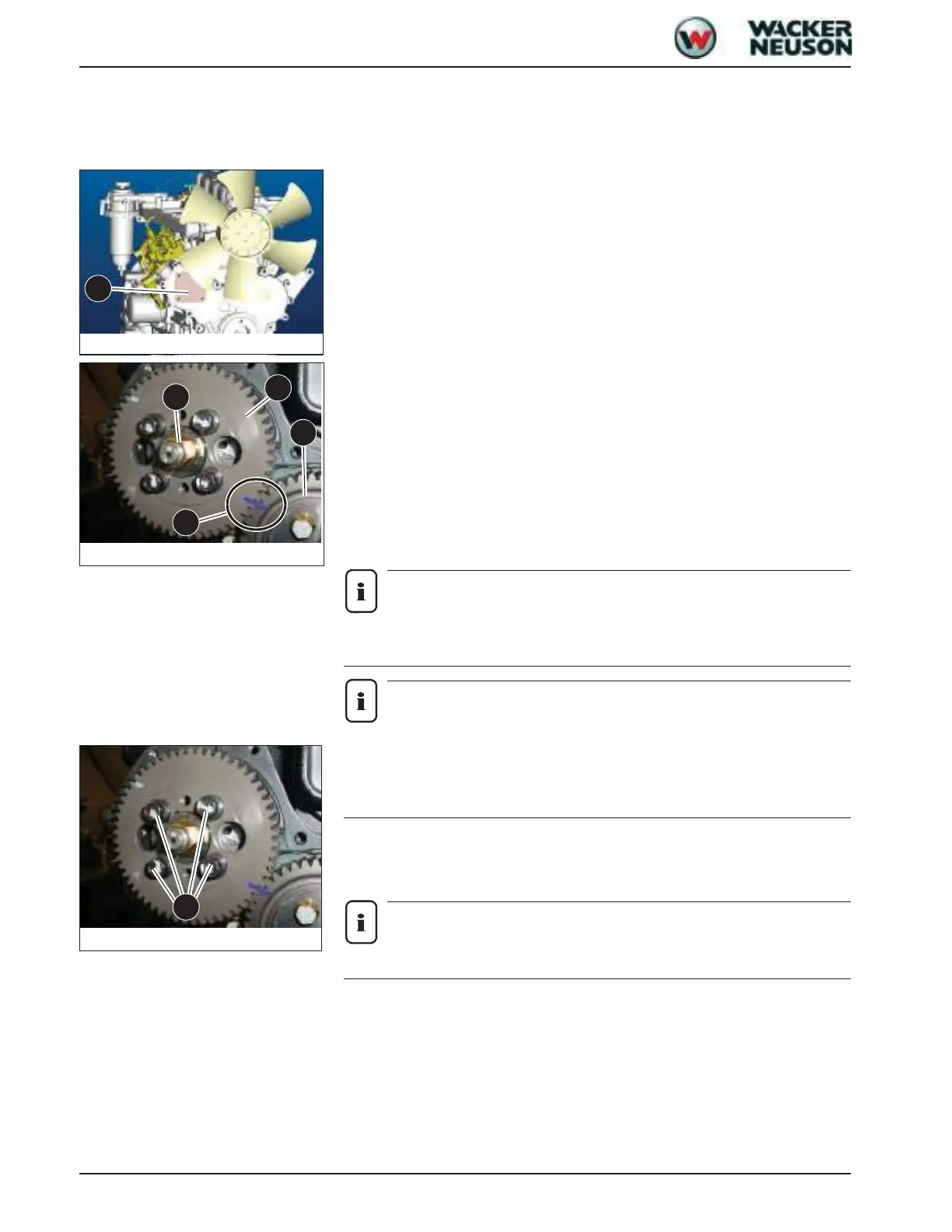

Fig. 14: Gear casing mark

E

B

D

C

Loading...

Loading...