Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

116 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

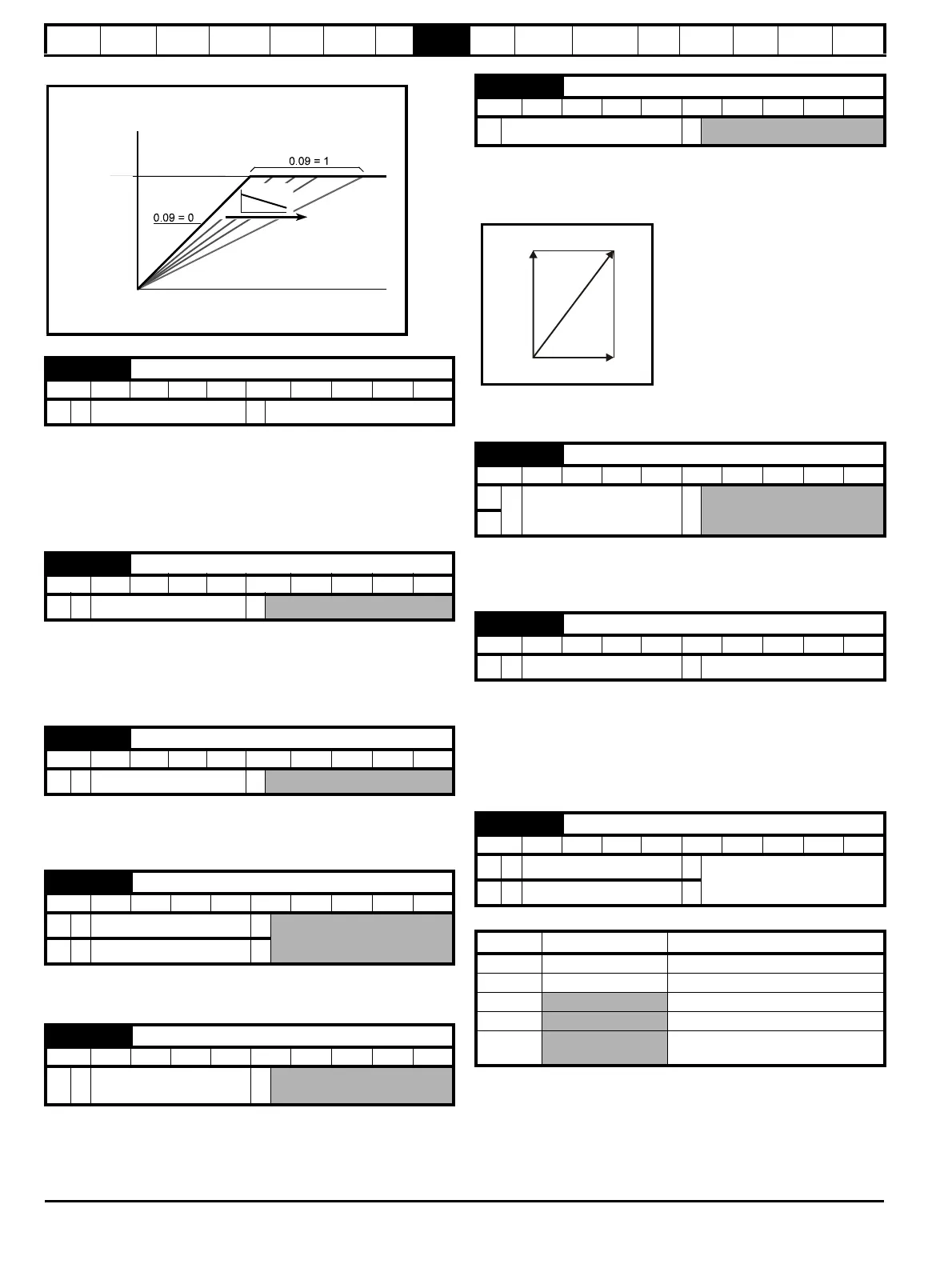

Figure 8-2 Fixed and variable V/f characteristics

Closed-loop

Pr 0.09 (3.12) operates in the feedback path of the speed-control loop in

the drive. See Figure 13-4 on page 174 for a schematic of the speed

controller. For information on setting up the speed controller gains, refer

to Chapter 10 Optimization on page 136.

8.2.5 Monitoring

Open-loop

Pr 0.10 (5.04) indicates the value of motor speed that is estimated from

the following:

0.12 Post-ramp frequency reference

0.42 Motor - no. of poles

Closed-loop

Pr 0.10 (3.02) indicates the value of motor speed that is obtained from

the speed feedback.

Open-loop & closed loop vector

Pr 0.11 displays the frequency at the drive output.

Servo

Pr 0.11 displays the position of the encoder in mechanical values of 0 to

65,535. There are 65,536 units to one mechanical revolution.

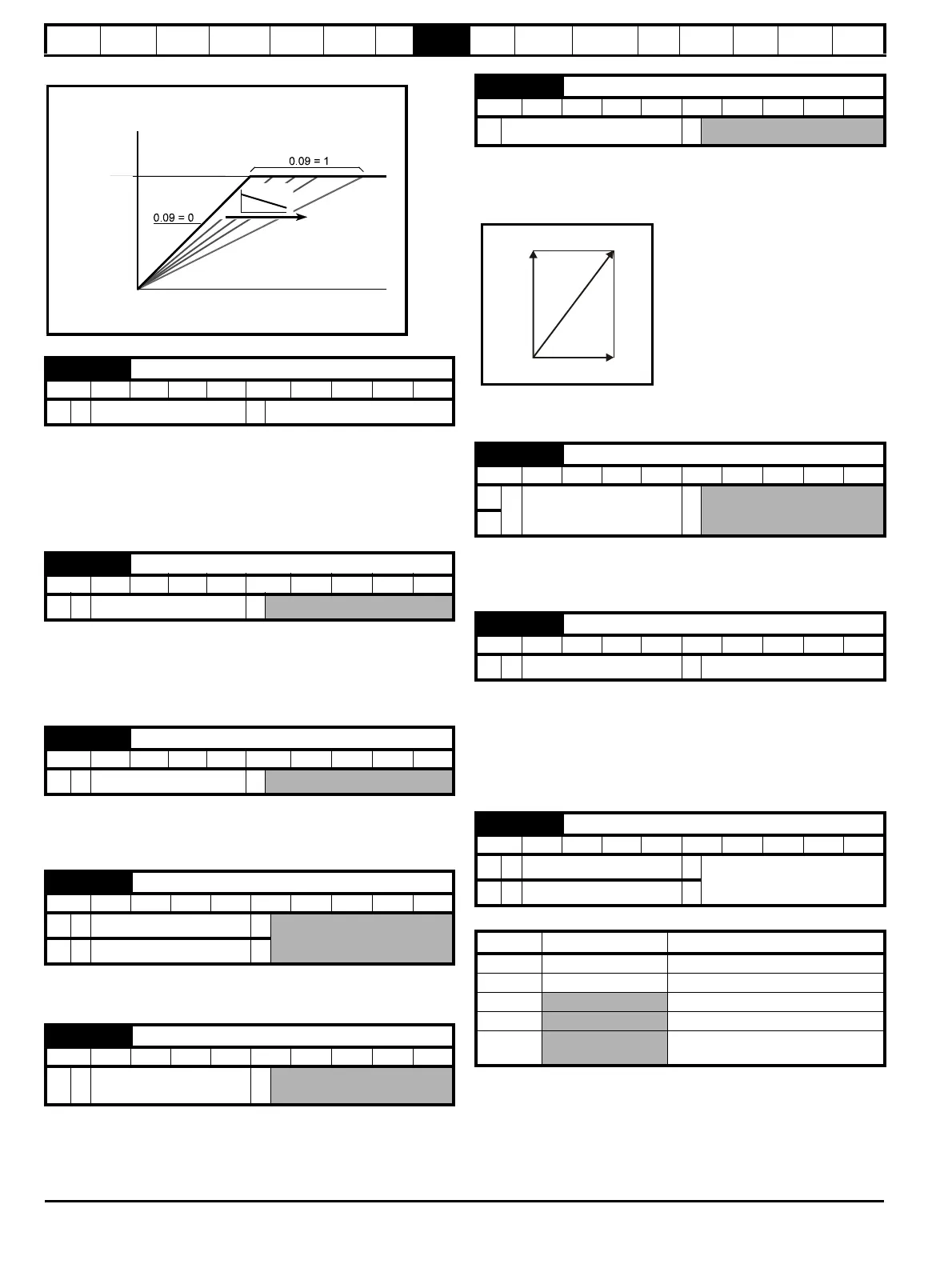

Pr 0.12 displays the rms value of the output current of the drive in each

of the three phases. The phase currents consist of an active component

and a reactive component, which can form a resultant current vector as

shown in the following diagram.

The active current is the torque producing current and the reactive

current is the magnetising or flux-producing current.

Open-loop & closed loop vector

When the motor is being driven below its rated speed, the torque is

proportional to [0.13].

Servo

Pr 0.13 can be used to trim out any offset in the user signal to analog

input 1.

8.2.6 Jog reference, Ramp mode selector, Stop and

torque mode selectors

Pr

0.14

is used to select the required control mode of the drive as follows:

0.09 {3.12} Speed controller differential feedback gain

RW Uni US

CL

Ú

0.00000 to 0.65535(s)

Ö

0.00000

0.10 {5.04} Estimated motor speed

RO Bit FI NC PT

OL

Ú

±180,000 rpm

Ö

0.10 {3.02} Motor speed

RO Bi FI NC PT

VT

Ú

±Speed_max rpm

Ö

0.11 {5.01} Drive output frequency

RO Bi FI NC PT

OL

Ú

±SPEED_FREQ_MAX Hz

Ö

VT

Ú

±1250.0 Hz

Ö

0.11 {3.29} Drive encoder position

RO Uni FI NC PT

SV

Ú

0 to 65,535

1/2

16

ths of a revolution

Ö

Motor

voltage

Frequency

AC supply

voltage

IMOTOR

0.12 {4.01} Total motor current

RO Uni FI NC PT

Ú

0 to Drive_current_max A

Ö

0.13 {4.02} Motor active current

RO Bi FI NC PT

OL

Ú

±Drive_current_max A

Ö

VT

0.13 {7.07} Analog input 1 offset trim

RW Bi US

SV

Ú

±10.000 %

Ö

0.000

0.14 {4.11} Torque mode selector

RW Uni US

OL

Ú

0 to 1

Ö

Speed control (0)

CL

Ú

0 to 4

Ö

Setting Open-Loop Closed-Loop

0 Frequency control Speed control

1 Torque control Torque control

2

Torque control with speed override

3

Coiler/uncoiler mode

4

Speed control with torque feed-

forward

Active

current

Total current

Magnetising current

Loading...

Loading...