Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Tec hnic al

Data

Diagnostics

UL Listing

Information

16 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

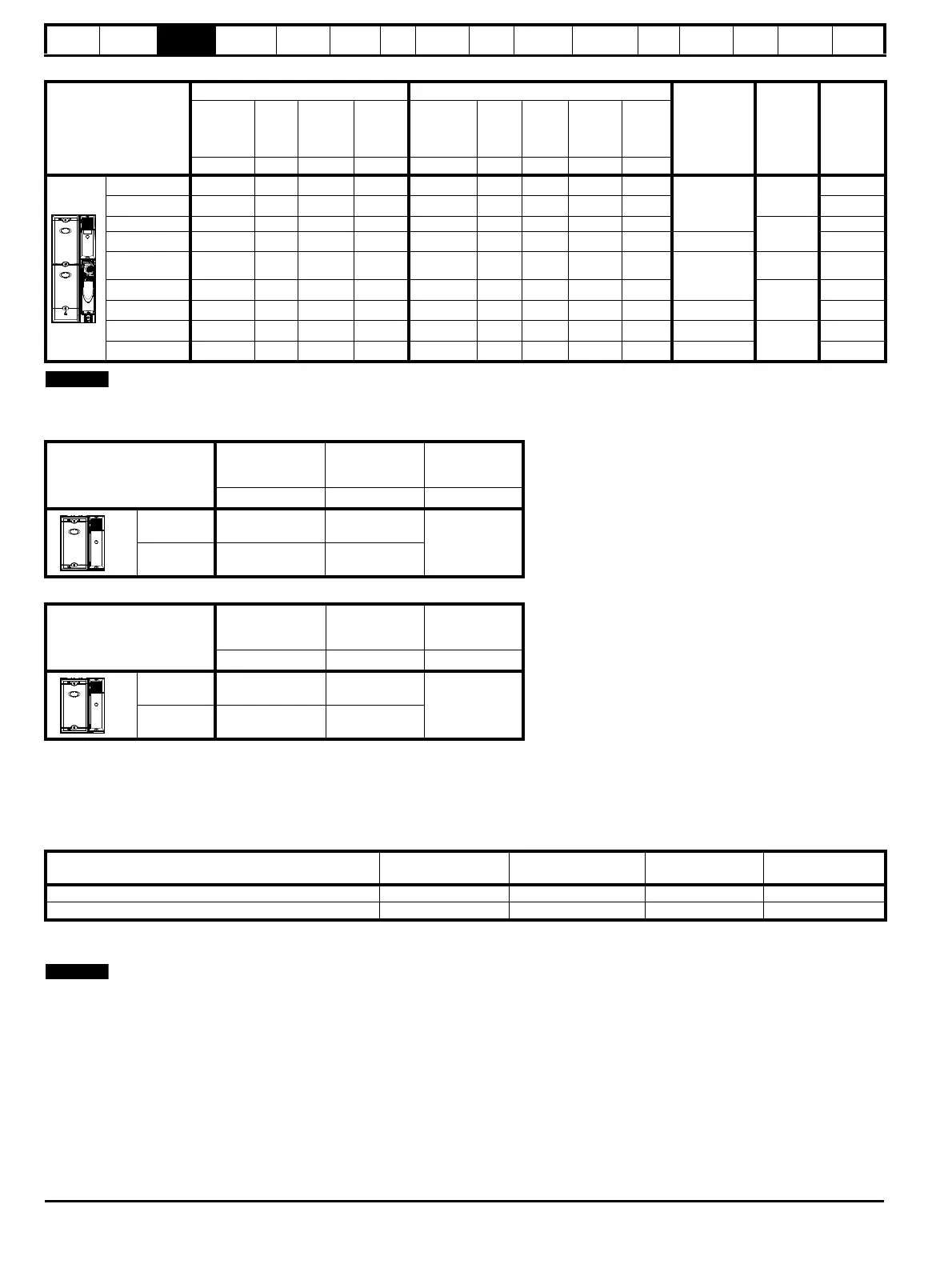

Table 3-10 Paralleled SPMD 690V motor drive ratings (500V to 690V ±10%) based on AC supply voltage

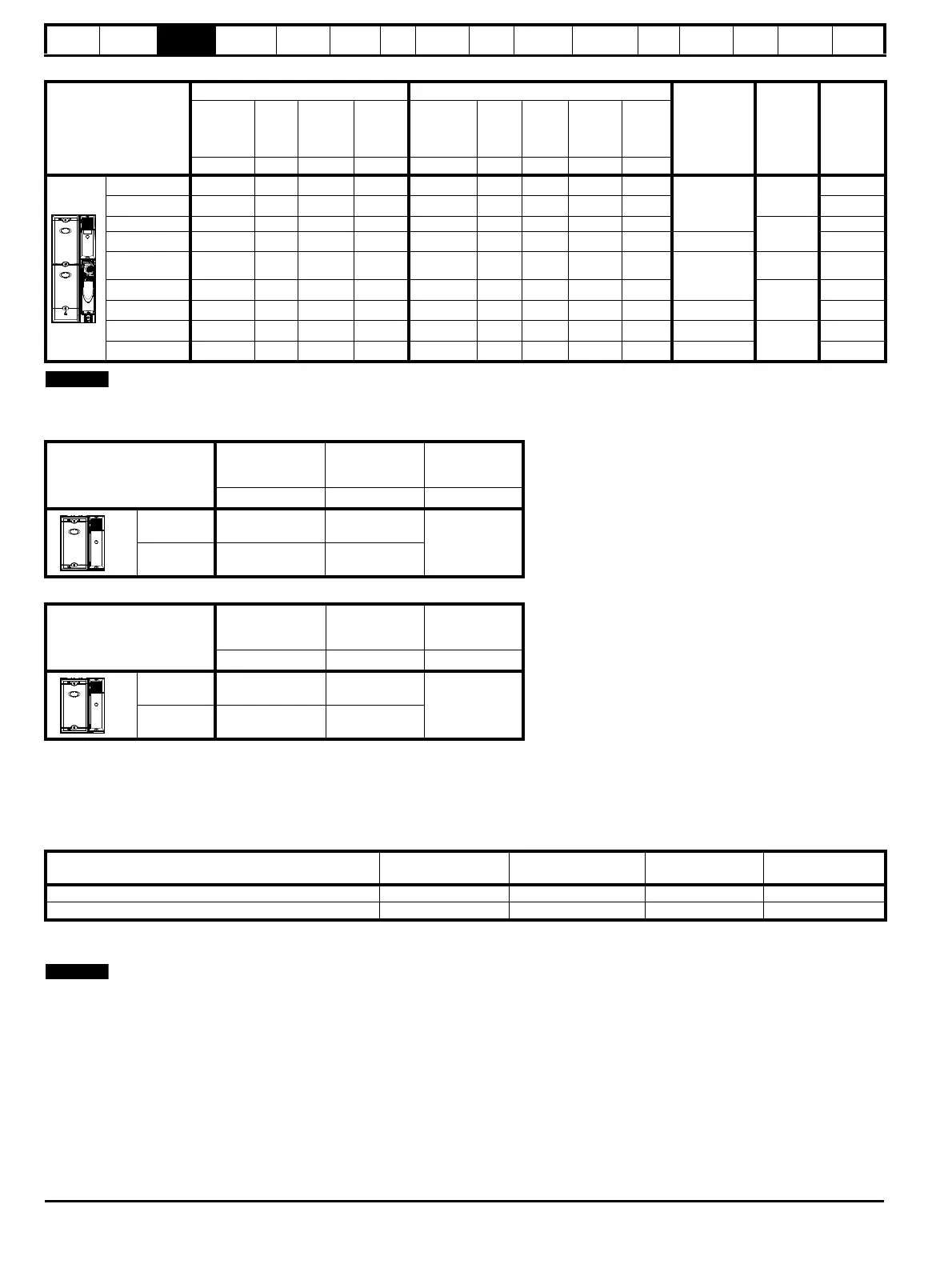

Table 3-11 Unidrive SPMC/U 400V ratings

Table 3-12 Unidrive SPMC/U 690V ratings

3.1.1 Typical short term overload limits

The maximum percentage overload limit changes depending on the selected motor. Variations in motor rated current, motor power factor and motor

leakage inductance all result in changes in the maximum possible overload. The exact value for a specific motor can be calculated using the

equations detailed in Menu 4 in the Unidrive SP Advanced User Guide.

Typical values are shown in the tables below for closed loop vector (VT) and open loop (OL) modes.

Table 3-13 Typical overload limits for all Unidrive SPM modules

Generally the drive rated current is higher than the matching motor rated current allowing a higher level of overload than the default setting.

The time allowed in the overload region is proportionally reduced at very low output frequency on some drive ratings.

The maximum overload level which can be attained is independent of the speed.

Paralleled SPMD modules

Normal Duty Heavy Duty

Required

rectifier

Required

input line

reactor

Required

output

sharing

choke

Maximum

continuous

output

current

Peak

current

Nominal

motor

power at

690V

Nominal

motor

power at

575V

Maximum

continuous

output

current

Open

loop

peak

current

Closed

loop

peak

current

Nominal

motor

power

at 690V

Nominal

motor

power at

575V

A AkW hp A AAkWhp

2 x SPMD16X1 237 261 250 250 190 244 284 200 200

1 x SPMC2601

1 x INL611

1 x OTL611

2 x SPMD16X2 273 300 280 300 237 305 356 250 250 1 x OTL612

2 x SPMD16X3 319 351 315 350 273 351 410 250 300

1 x INL612

1 x OTL613

2 x SPMD16X4 364 401 315 350 319 410 478 280 350 2 x SPMC1601 1 x OTL614

3 x SPMD16X2 410 451 450 450 356 457 534 355 400

1 x SPMC2601

+

1 x SPMC1601

1 x INL611 +

1 x INL601

3 x OTL602

3 x SPMD16X3 478 526 500 500 410 527 615 450 450

1 x INL612 +

1 x INL602

3 x OTL603

3 x SPMD16X4 547 601 545 600 478 615 718 450 500 3 x SPMC1601 3 x OTL604

4 x SPMD16X3 638 702 630 700 547 703 820 545 600 2 x SPMC2601

2 x INL612

4 x OTL603

4 x SPMD16X4 729 802 710 800 638 820 957 630 700 4 x SPMC1601 4 x OTL604

When connecting drives in parallel they must be derated. Table 3-2, Table 3-4, Table 3-6, Table 3-8 and Table 3-10 have already the

required de-rating.

Model

Maximum

AC input current

Maximum DC

output current

External 24V

current

consumption

AAA

SPMC/U1402

344 379

3.0

SPMC/U2402

2 x 312 2 x 345

Model

Maximum AC input

current

Maximum DC

output current

External 24V

current

consumption

AAA

SPMC/U1601 195

209

3.0

SPMC/U2601 2 x 173

2 x 185

Operating mode

Closed loop/RFC/

Servo/Regen from cold

Closed loop/RFC/Servo/

Regen from 100%

Open loop from cold Open loop from 100%

Normal Duty overload with motor rated current = drive rated current 110% for 165s 110% for 9s 110% for 165s 110% for 9s

Heavy Duty overload with motor rated current = drive rated current 150% for 60s 150% for 8s 129% for 97s 129% for 15s

Loading...

Loading...