Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

68 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

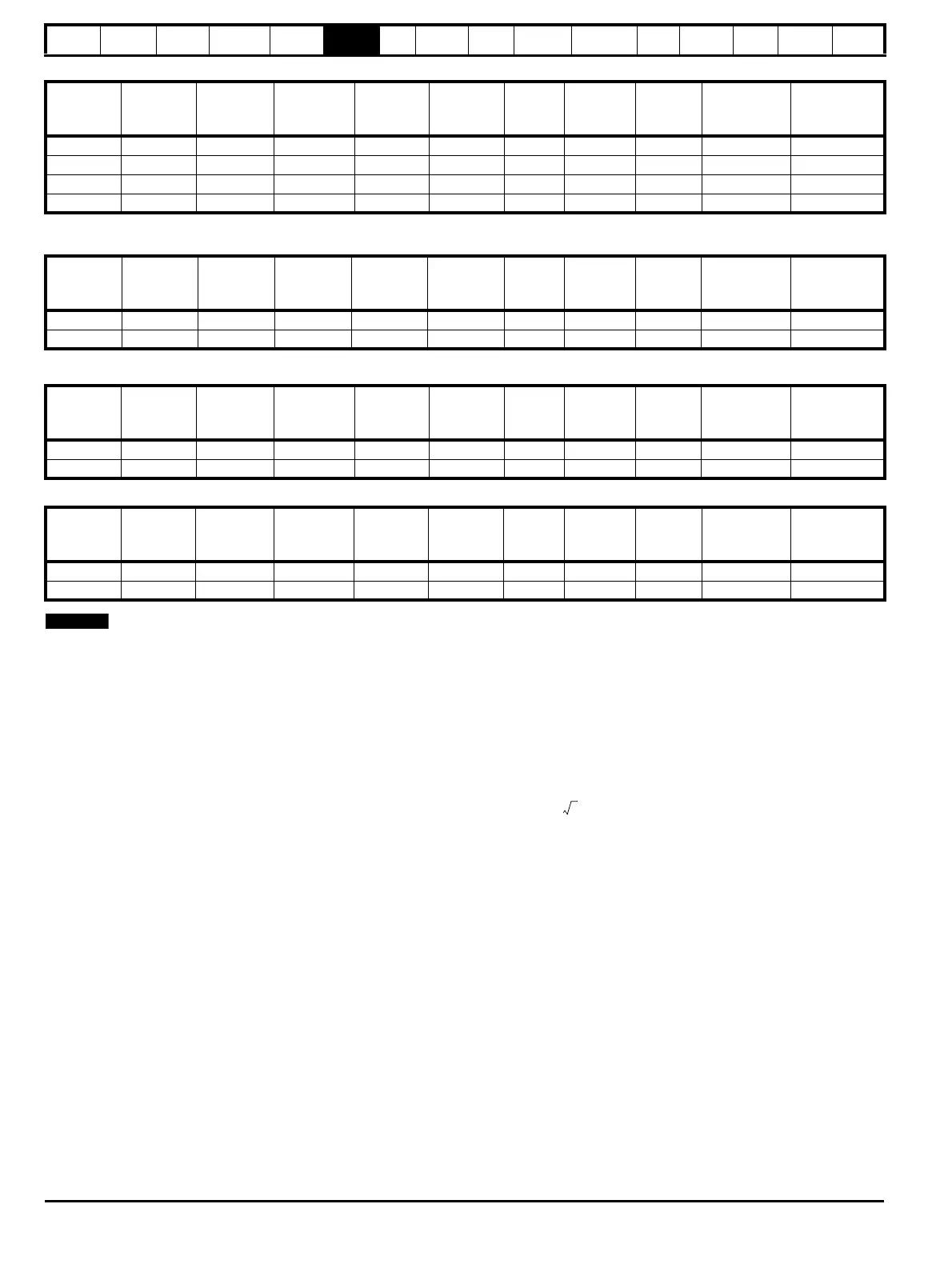

Table 6-2 400V input line reactor ratings

*May represent a more economic solution where operating temperature and cooling requirements are observed.

Table 6-3 400V dual input line reactor ratings

Table 6-4 690V input line reactor ratings

Table 6-5 690V dual input line reactor ratings

N

The INLX1X parallel line reactors have been designed to work in

conjunction with the Unidrive SPMC/U, allowing one reactor to be used

with the dual rectifier model or two separate rectifier units.

6.2.3 Supplies requiring additional line reactance

Additional line reactance reduces the risk of damage to the drive resulting

from poor phase balance or severe disturbances on the supply network. It

also reduces harmonic current emission. It can be implemented by

adding external reactors with SPMA modules, and by adding additional

series reactors or increased reactance values with rectifier modules.

Where additional line reactance is to be used, added reactance of

approximately 2% is recommended. Higher values may be used if

necessary, but may result in a loss of drive output (reduced torque at

high speed) because of the voltage drop.

For all drive ratings, 2% additional reactance permits drives to be used

with a supply unbalance of up to 3.5% negative phase sequence

(equivalent to 5% voltage imbalance between phases).

Severe disturbances may be caused by the following factors, for example:

• Power factor correction equipment connected close to the drive.

• Large DC drives having no or inadequate line reactors connected to

the supply.

• Direct-on-line started motor(s) connected to the supply such that

when any of these motors are started, the voltage dip exceeds 20%.

Such disturbances may cause excessive peak currents to flow in the

input power circuit of the drive. This may cause nuisance tripping, or in

extreme cases, failure of the drive.

Drives of low power rating may also be susceptible to disturbance when

connected to supplies with a high rated capacity.

When required, each drive must have its own reactor(s). Three individual

reactors or a single three-phase reactor should be used.

Reactor current ratings

The current rating of the line reactors should be as follows:

Continuous current rating:

Not less than the continuous input current rating of the drive

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive

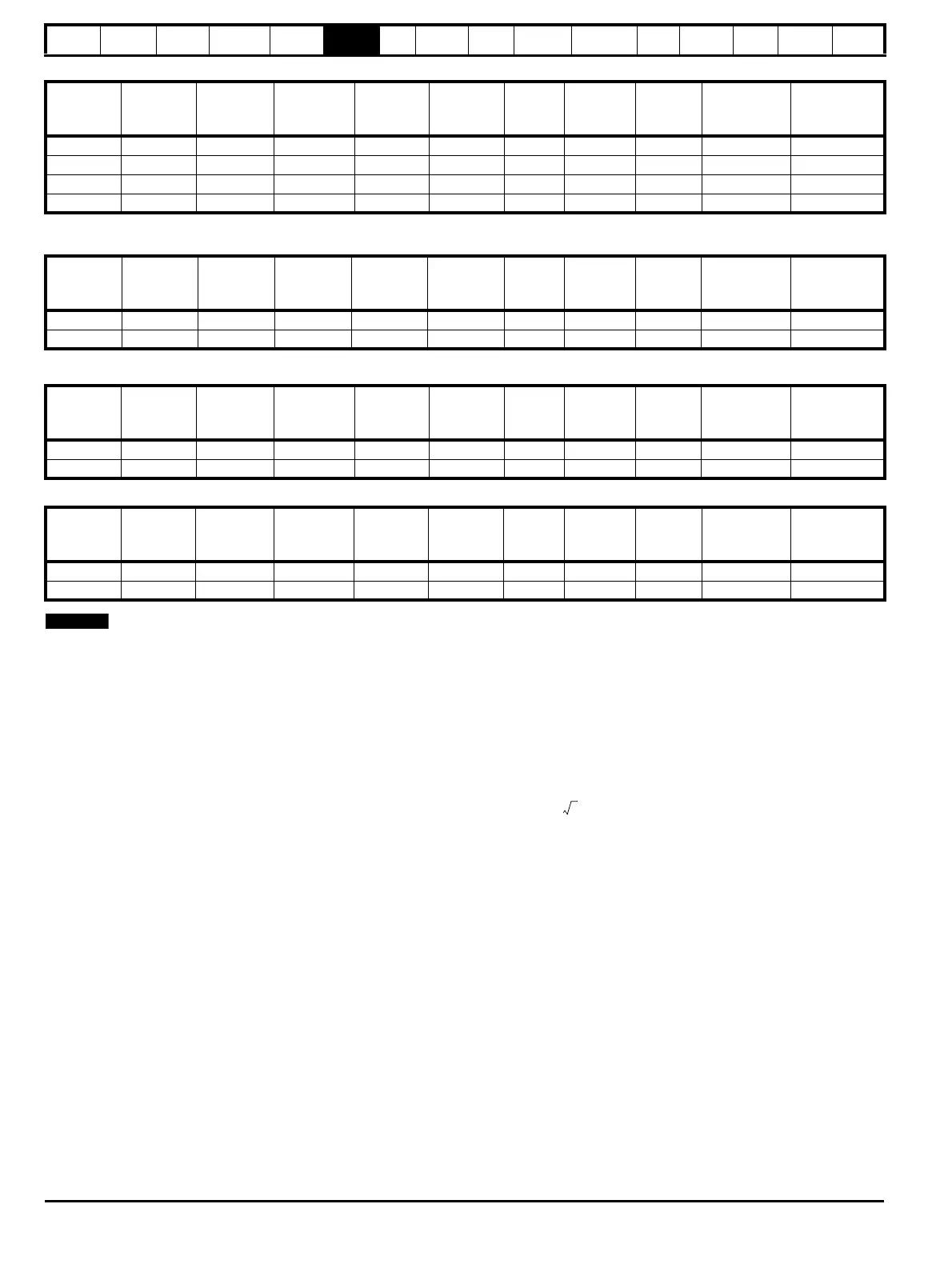

6.2.4 Additional input inductance calculation

To calculate the additional inductance required (at Y%), use the following

equation:

Where:

I = drive rated input current (A)

L = inductance (H)

f = supply frequency (Hz)

V = voltage between lines

Model

Current

A

Inductance

μH

Overall

width (W)

mm

Overall

depth (D)

mm

Overall

height (H)

mm

Weight

kg

Max

ambient

temp (°C)

Min

airflow

(m/s)

Quantity

required

Part No.

INL 401 245 63 240 190 225 32 50 1 1 4401-0181

INL 402 339 44 276 200 225 36 50 1 1 4401-0182

INL 401W* 245 63 255 235 200 27 40 3 1 4401-0208

INL 402W* 339 44 255 235 200 27 40 3 1 4401-0209

Model

Current

A

Inductance

μH

Overall

width (W)

mm

Overall

depth (D)

mm

Overall

height (H)

mm

Weight

kg

Max

ambient

temp (°C)

Min

airflow

(m/s)

Quantity

required

Part No.

INL411 2 x 245 2 x 31.5 320 220 360 55 50 1 1 4401-0206

INL412 2 x 339 2 x 22 320 220 360 55 50 1 1 4401-0207

Model

Current

A

Inductance

μH

Overall

width (W)

mm

Overall

depth (D)

mm

Overall

height (H)

mm

Weight

kg

Max

ambient

temp (°C)

Min

airflow

(m/s)

Quantity

required

Part No.

INL 601 145 178 240 190 225 33 50 1 1 4401-0183

INL 602 192 133 276 200 225 36 50 1 1 4401-0184

Model

Current

A

Inductance

μH

Overall

width (W)

mm

Overall

depth (D)

mm

Overall

height (H)

mm

Weight

kg

Max

ambient

temp (°C)

Min

airflow

(m/s)

Quantity

required

Part No.

INL 611 2 x 145 2 x 89 320 220 360 40 50 1 1 4401-0190

INL 612 2 x 192 2 x 66.5 320 220 360 55 50 1 1 4401-0191

L

Y

100

----------

V

3

-------

×

1

2πfI

------------

×=

Loading...

Loading...