Emerson Process Management GmbH & Co. OHG 3-5

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

10/2012

3

Measuring Principles

3.2 Oxygen Measurement

3.2 Oxygen Measurement

Three different principles are used for measu-

ring oxygen concentrations. The principle

used in your specic instrument is given by the

channel code (sample gas designator) on the

nameplate label ( gure on page 2-22):

pO

2

= paramagnetic sensor

eO

2

= electrochemical sensor

tO

2

= trace oxygen sensor

3.2.1 Paramagnetic Measurement

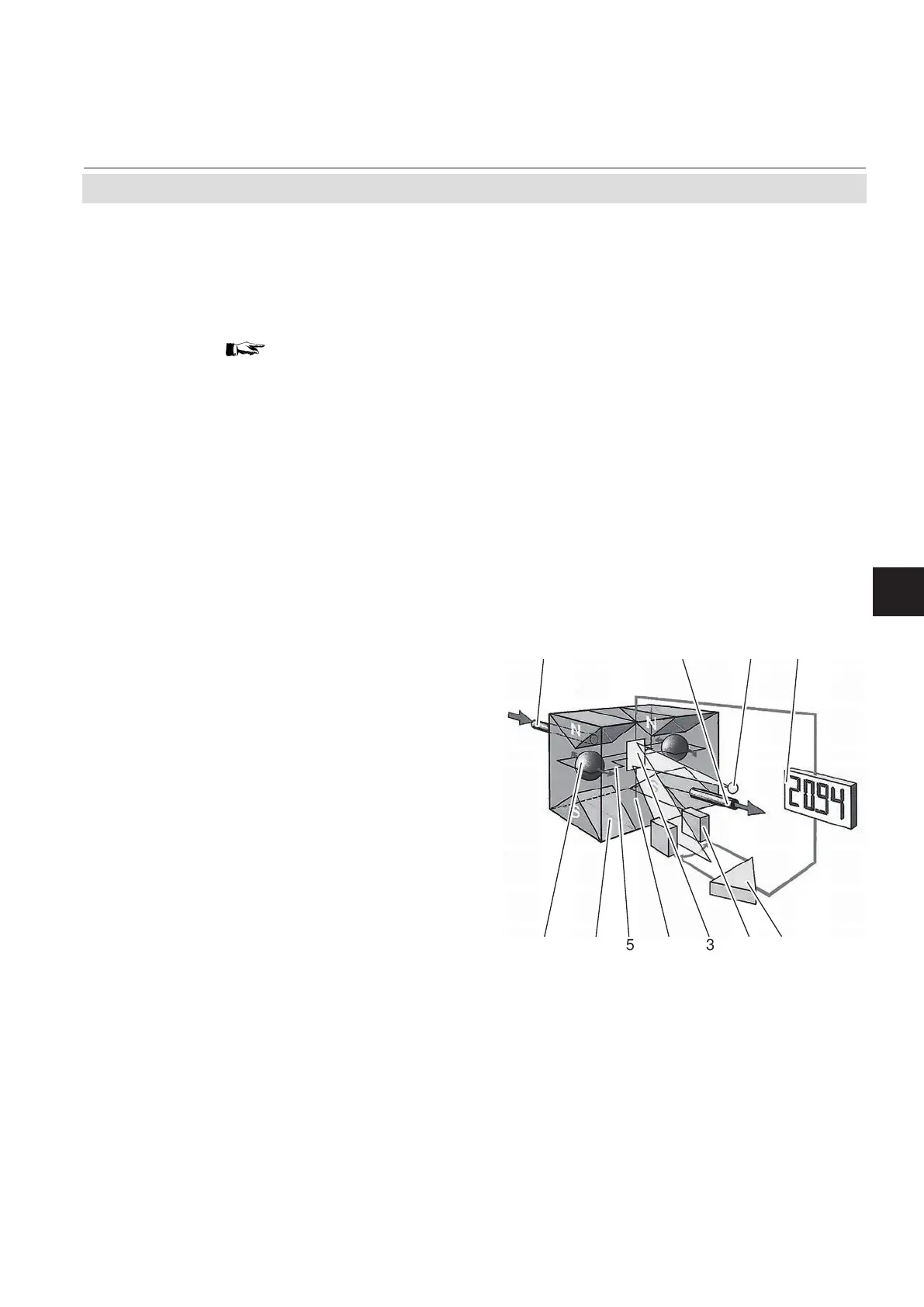

Fig. 3-4: Paramagnetic Oxygen Sensor -

Assembly Principle

1 Permanent magnet

2 Platinum wire

3 Mirror

4 Glass ball

5 Loop

6 Photodetector

7 Light source

8 Preamplier

9 Display

10 Gas inlet

11 Gas outlet

4 1 5 3 6 8

11 7 9

2

10

This oxygen measurement principle is based

on the paramagnetic characteristic of oxygen

molecules:

Two cavernous glass spheres lled with nitro-

gen are arranged in a dumb¬bell conguration.

This dumbbell with a platinum wire is mounted

rotatable inside a strong inhomogeneous ma-

gnetic eld. A small mirror is xed on the front

side of the dumbbell, which reects light from a

light source towards two photo detectors (Fig.

3-4). The dumbbell is surrounded by another

platinum wire, which is bent like a coil around

each glass sphere. It generates a magnetic

eld when supplied by an electric current to

control the dumpbell´s deection.

Oxygen molecules within the sample gas

are attracted be the magnetic eld due to

their paramagnetic characteristic and will

be concentrated into the area of the highest

eld strength in the inhomogeneous eld.

In doing so they displace the nitrogen lled

glass spheres. This generates a torque on

the dumbbell which depends on the oxygen

concentration in the sample gas. The dumbbell

starts to rotate and the light reected by the

mirror on the dumbbell generates a signal on

one of the two photo detectors. Initiated by the

photo detector signal a preamplier drives a

current through the platinum wire surrounding

the dumbbell. This generates a compensating

magnetic eld and rotates the dumbbell back

into its zero position. The compensating cur-

rent gives a direct and linear measure for the

oxygen concentration within the sample gas.

The paramagnetic oxygen detector also

con¬tains a temperature sensor for compen-

sation and a heating ele¬ment to keep the

detector at approx. 55 °C.

Several variations are available including

corrosion resistant, solvent resistant and/or

intrinsically safe (for measuring ammable

gases) versions.

Loading...

Loading...