Emerson Process Management GmbH & Co. OHG3-10

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

10/2012

3.2 Oxygen Measurement

Due to the measuring principle the electro-

chemical oxygen cell requires a minimum

internal consumption of oxygen (residual

humidity avoids drying of the cell). Supplying

cells continuously with dry sample gas of low

grade oxygen concentration or with sample

gas free of oxygen could result in a reversible

detuning of O

2

sensitivity. The output signal will

become unstable, but response time remains

constant.

For correct measurement the cell needs con-

tinuously to be supplied with concentrations

of at least 0.1 Vol.-% O

2

. We recommend to

use the cells if need be in alternating mode,

means to purge cells with conditioned (not

dried, but dust removed) ambient air when

measurement pauses.

If it is necessary to interrupt the oxygen sup-

ply for several hours or days, the cell has to

regenerate (supply cell for about one day with

ambient air). Temporarily ushing with nitrogen

(N

2

) for less than 1 h (e.g. for analyzer zero-

ing purpose) has no inuence on measuring

characteristics.

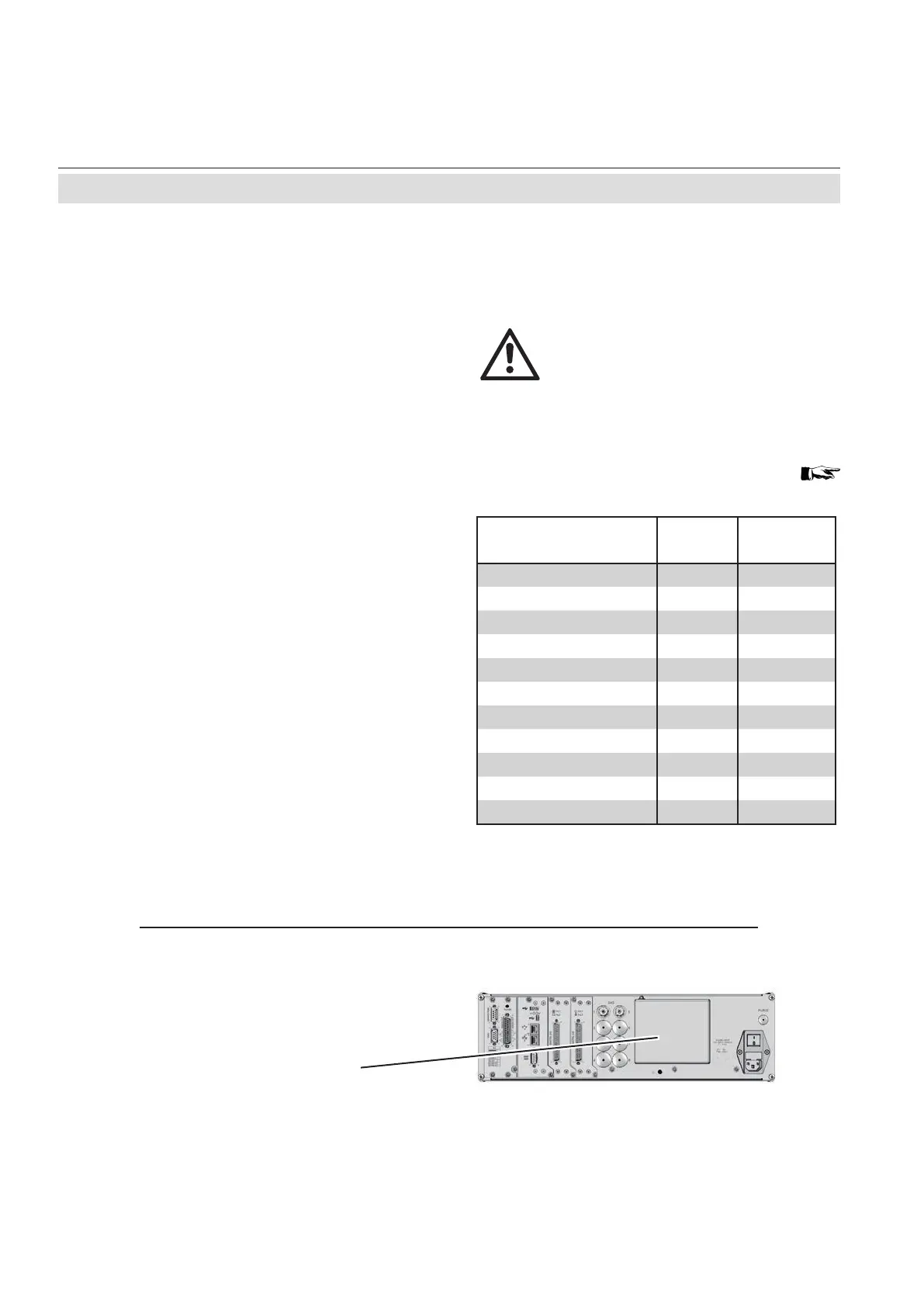

Gas

Concen-

tration

Interference

Level

Carbon monoxide CO 0-100 % no effect

Carbon dioxide CO

2

0-100 % no effect

Nitric monoxide NO 0-1 % no effect

Nitrogen dioxide NO

2

0-1 % no effect

Sulfur dioxide SO

2

0-3 % 3 %

Hydrogen sulde H

2

S 0-3 % no effect

Ammonia NH

3

0-3 % 1 %

Hydrogen H

2

0-100 % no effect

Hydrogen chloride HCl 0-3 % 1 %

Benzene C

6

H

6

0-100ppm 1 %

Methane CH

4

0-100 % no effect

Tab. 3-4:

Electrochemical Oxygen Measurement -

Cross Interference by Accompanying

Gases

3.2.2.1 Special Hints

This sensor is not suitable for

•

anorganic gases containing

chlorene or ourene!

• sample gases containing

• FCHCs

• ozone,

• H

2

S (> 100 ppm)

• NH

3

(> 20 ppm).

For a number of other interfering gases

Tab. 3-4.

Note for XEGP analyzers!

If the XEGP analyzer features thermostate

control, the eO2 sensor block is installed at

the XEGP rear panel.

Fig. 3-8: Cover for EO2 Sensor Block At Rear Panel

Cover

Loading...

Loading...