GEK-106310AB F650 Digital Bay Controller 5-161

5 SETTINGS 5.10 LOGIC CONFIGURATION (PLC EDITOR)

5

Users can build their own libraries and distribute them in their projects in an easy way.

The manufacturer provides default libraries such as ORs, ANDs of 3 up to 8 inputs, besides timers (pickup-dropout) and

key examples.

5.10.5 GENERATION OF LIBRARIES

Libraries can contain a set of operations grouped in a single graphic object being formed by inputs, outputs and operations

Working with libraries follows the same procedure as working in the main project menu, the only difference is that the inputs

and outputs to the library must be selected as external inputs and outputs. The rest of variables are internal variables used

in the logic compilation.

The name assigned to the inputs and outputs of the library and to the library itself will be ones used to represent the library

as an object in the main project.

Internal variables inside the libraries will be assigned randomly when compiling.

These libraries are saved in the LIB folder in order to be used in further projects

5.10.5.1 LIBRARY EXAMPLE

Go to the main menu File >Library > Open Library

> New Library

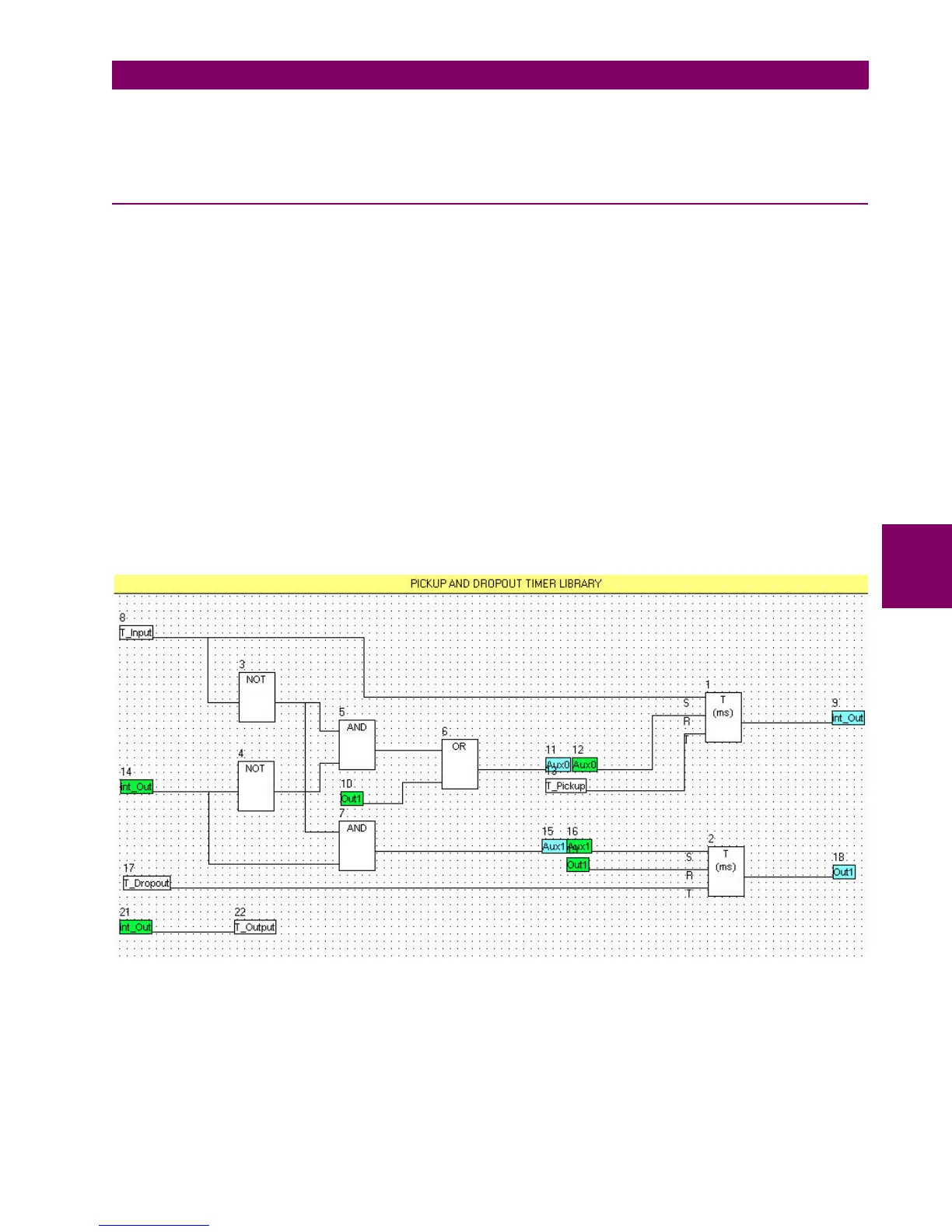

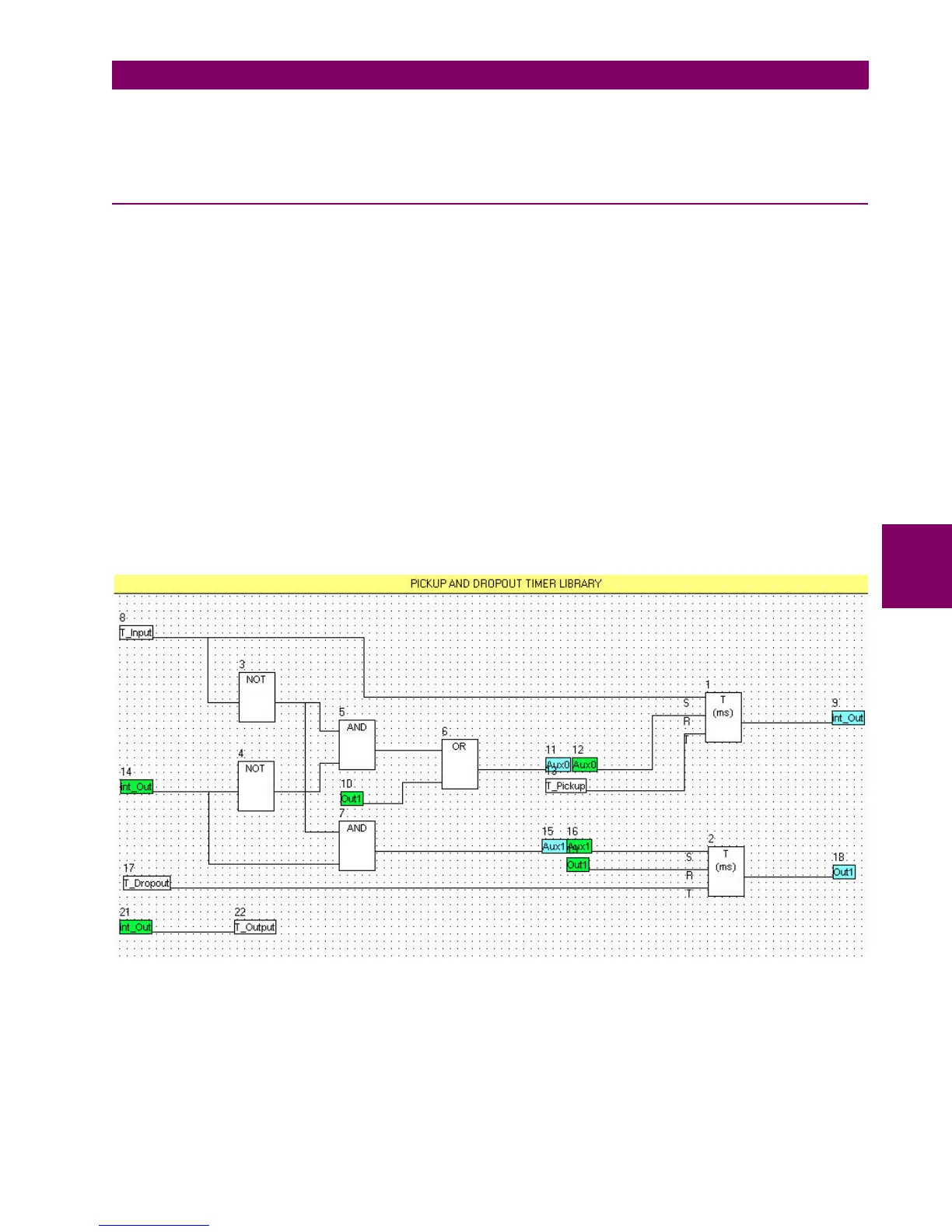

Open a new library or modify an existing one, in this example a timer library is going to be displayed Timer (Pkp-Dpt).lib as

shown on Figure 5–57:

Figure 5–57: TIMER (PKP-DPT).LIB CONFIGURATION EXAMPLE

Green and blue signals are internal inputs and outputs used in the library and are not going to be accessible to the user

when working in the main menu outside the library environment. The white boxes (T_Input, T_Pickup, T_Dropout,

T_output) are inputs and outputs to the library that are going to be accessible to the user to connect the library in the main

application to create virtual outputs to be sent to the relay.

Loading...

Loading...