CHAPTER 4: SETPOINTS CONTROL

869 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 4–323

Start Supervision

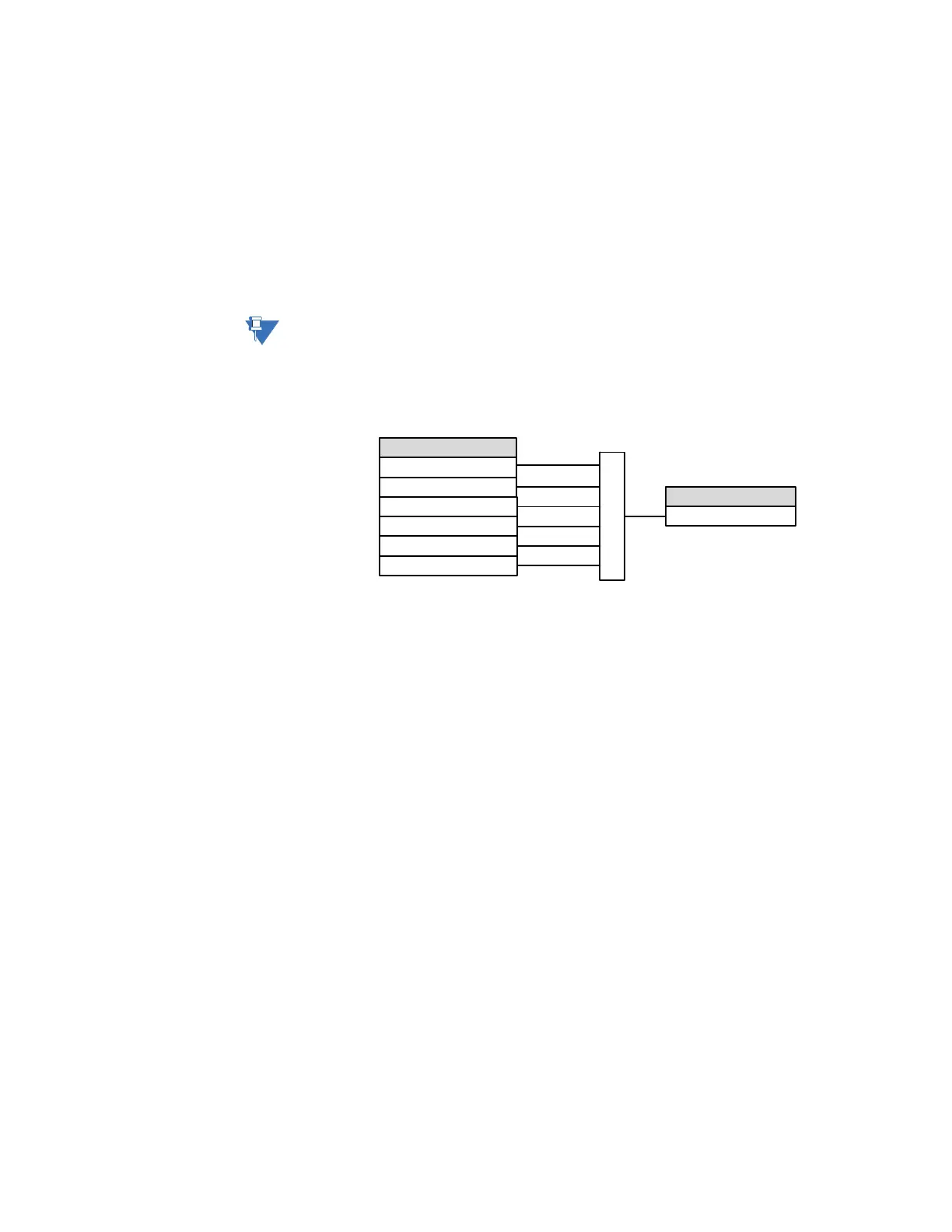

Start Supervision consists of four elements that guard against excessive starting duty. All

Start Supervision elements operate the FlexLogic operand Output Relay 3 (“Start Inhibit”).

In addition to Start Supervision elements, the Start Inhibit operand relay also operates

when the Phase Reversal element or Any Trip operates, as shown in the following figure:

Start Inhibit FlexLogic operand. If the condition that has caused the trip is still present (e.g.

hot RTD), the Start Inhibit operand relay will not reset until the condition is no longer

present or the lockout time has expired. Auxiliary Output Relay, energized by the Start

Inhibit operand, changes state only when the motor is stopped to accommodate control

circuits that must be continuously energized, such as a contactor.

NOTE:

The Start Inhibit operand is programmed as factory default to energize the auxiliary

Output Relay 3, therefore, it is recommended to use the auxiliary Output Relay 3 to inhibit

the closing of the motor switching device, as illustrated by the figure: Typical Wiring

Diagram in chapter 2.

Figure 4-128: Start Inhibit FlexLogic operand

The four elements of Start Supervision are: Thermal Start Inhibit, Maximum Starting Rate,

Time Between Starts, and Restart Delay.

Thermal Inhibit

This function is provided to inhibit starting of a motor if there is insufficient thermal

capacity (TC) available for a successful start. The thermal capcity required for a successful

start or the learned thermal capacity used at start (TC

L

) is calculated even if the Thermal

Start Inhibit element is disabled.

The information about learned thermal capacity is stored in a non-volatile memory and it is

a

vailable after the power is removed from the 869 . The TC

L

is the largest thermal capacity

used value from a number (N) of most recent successful starts. “N” is set in

Setpoints >

System > Motor > Setup > Number of Starts to Learn

. A successful motor start is one in

which the motor reaches the Running state. See the Motor Status section of this manual

for a description of Running state logic. When the start history is not available or “Clear

Learned TCU” command (in Records > Clear Records) is executed, a value of 85% is used

for the learned thermal capacity used until displaced by the largest of the “N” subsequent

successful starts. This 85% default requires the thermal capacity used to decay to the 15%

level before the start is allowed.

Starts are inhibited while the thermal capacity is greater than the adjusted thermal

cap

acity (TC

ADJ

) subtracted from 100%. TC

ADJ

is equal to the learned thermal capacity

used at start (learned start TCU or TC

L

) increased by the margin (TC Used Margin). The

formula is TC

ADJ

= TC

L

+ (TC Used Margin / 100%) x TC

L

.

For example, if the thermal capacity used for

the last 5 starts is 24, 23, 27, 26 and 20%

respectively, the learned starting capacity used at start is the Maximum of (24%, 23%,

27%, 26%, 20%) = 27%. If the set margin is 25%, the adjusted thermal capacity learned

value (TC

ADJ

) is calculated as 27% x (1+25%/100%) = 33.75%. A start inhibit is issued until

the motor current TCU decays to 100% - 33.75 = 66.25%. For more details, please see the

Thermal Start Inhibit logic diagram.

FlexLogic Operand

Start Inhibit

FlexLogic Operands

Thermal Inhibit OP

OR

Max Start Rate OP

Time Btwn Start OP

Restart Delay OP

Phase Rev Inhibit

Any Trip

Loading...

Loading...