IGNITION

IGNITION SYSTEM TESTS

IGNITION SYSTEM

TESTS

~

CAUTION

~

All

cranking

output

tests

must

be per-

formed

with

spark plugs installed and

torqued

in the cylinder head.

If

necessary

to

remove the spark plugs, be sure

to

keep

the

spark

tester away from open spark

plug

holes.

The

following series of steps will systematically

isolate

a problem area

in

the ignition system.

To

reduce your troubleshooting time and to avoid

incomplete results, perform these steps

in

the

order written.

Total

Ignition

Output Test

~

CAUTION

~

To

avoid possible

shock

hazard,

do

not

handle

ignition

coils

or

spark tester

during

cranking tests.

Twist and remove the

leads from both spark plugs.

Adjust the gap

on

the spark tester to 1/2

in.

(12

mm). Connect tester leads

to

the spark plug leads.

Secure tester clip

to

a clean engine ground.

C0A4308

IMPORTANT:

To

prevent high voltage arc, route

tester

leads at least 2

in.

(51

mm)

from any metal

surface.

120

If

equipped, install the clip onto the emergency

stop switch. Crank the engine. Spark

should jump

each tester gap

alternately.

•

If

tester shows good output

on

both cylinders,

go to Power Pack Running

Output

on

p.

125.

•

If

tester shows good output

on

one cylinder, go

to

Power Pack Cranking

Output

on

p.

124.

•

If

tester shows no output,

go

to Stop

Circuit

Tests.

IMPORTANT:

It

is

possible for the ignition sys-

tem

to have a problem but still produce good out-

put.

If

the engine pops or backfires during starting,

the ignition may

be

out of time. Check the follow-

ing

:

• Coil primary wire routing

• Spark plug lead routing

• Flywheel condition

and

location

•

Synchronization and linkage adjustments

Stop

Circuit

Tests

~

CAUTION

~

To

avoid possible

shock

hazard,

do

not

handle ignition coils

or

spark tester

during

cranking tests.

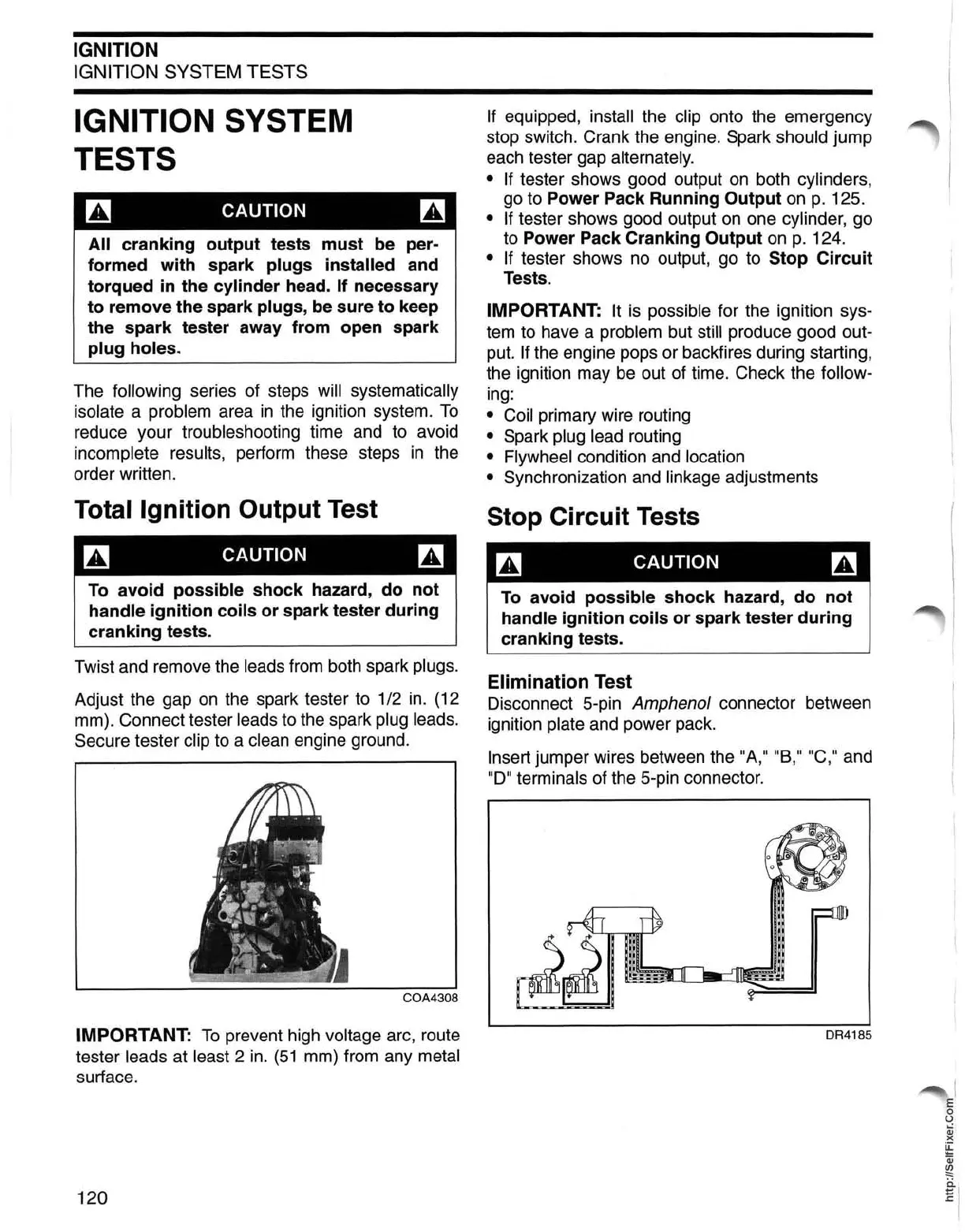

Elimination Test

Disconnect 5-

pin

Amphenol connector between

ignition

plate and power pack.

Insert jumper wires between the "A," "B,"

"C

," and

"0" terminals of the 5-pin connector.

DR4185

Loading...

Loading...