POWERHEAD

INSPECTION

25/30 Models

The difference between your measurements and

standard bore dimension

is

cylinder oversize.

Refer to

TECHNICAL DATA

on

p. 30 for dimen-

sions.

• The cylinder must not

be

oversize by more than

0.003 in. (0.08 mm).

IMPORTANT: If any cylinder

is

outside these tol-

erances, it must

be

bored oversize. One oversize

piston

is

available for this engine 0.030 in.

(0

.762

mm).

To

determine oversize bore, add 0.030

in

.

(0.762 mm) to the standard bore. Refer to TECH-

NICAL DATA

on

p.30.

It

is

permissible to have

one or more oversize pistons

in

an

engine.

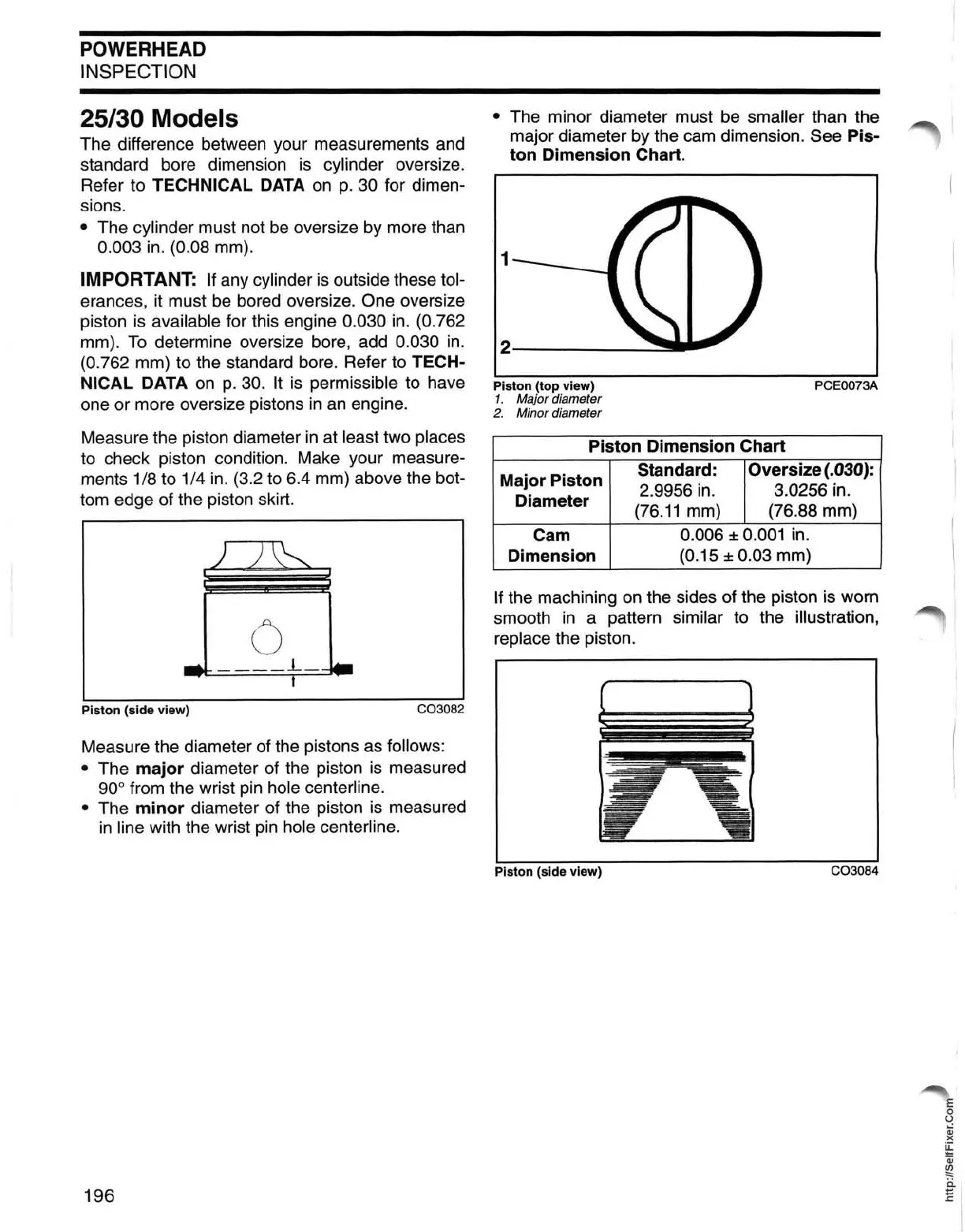

Measure the piston diameter

in

at least two places

to

check piston condition. Make your measure-

ments 1/8 to 1/4

in.

(3.2 to 6.4 mm) above the bot-

tom edge of the piston skirt.

Piston

(side view)

C03082

Measure the diameter of the pistons as follows:

•

The

major

diameter of the piston

is

measured

90° from the wrist pin hole centerline.

•

The

minor

diameter of the piston is measured

in

line with the wrist pin hole centerline.

196

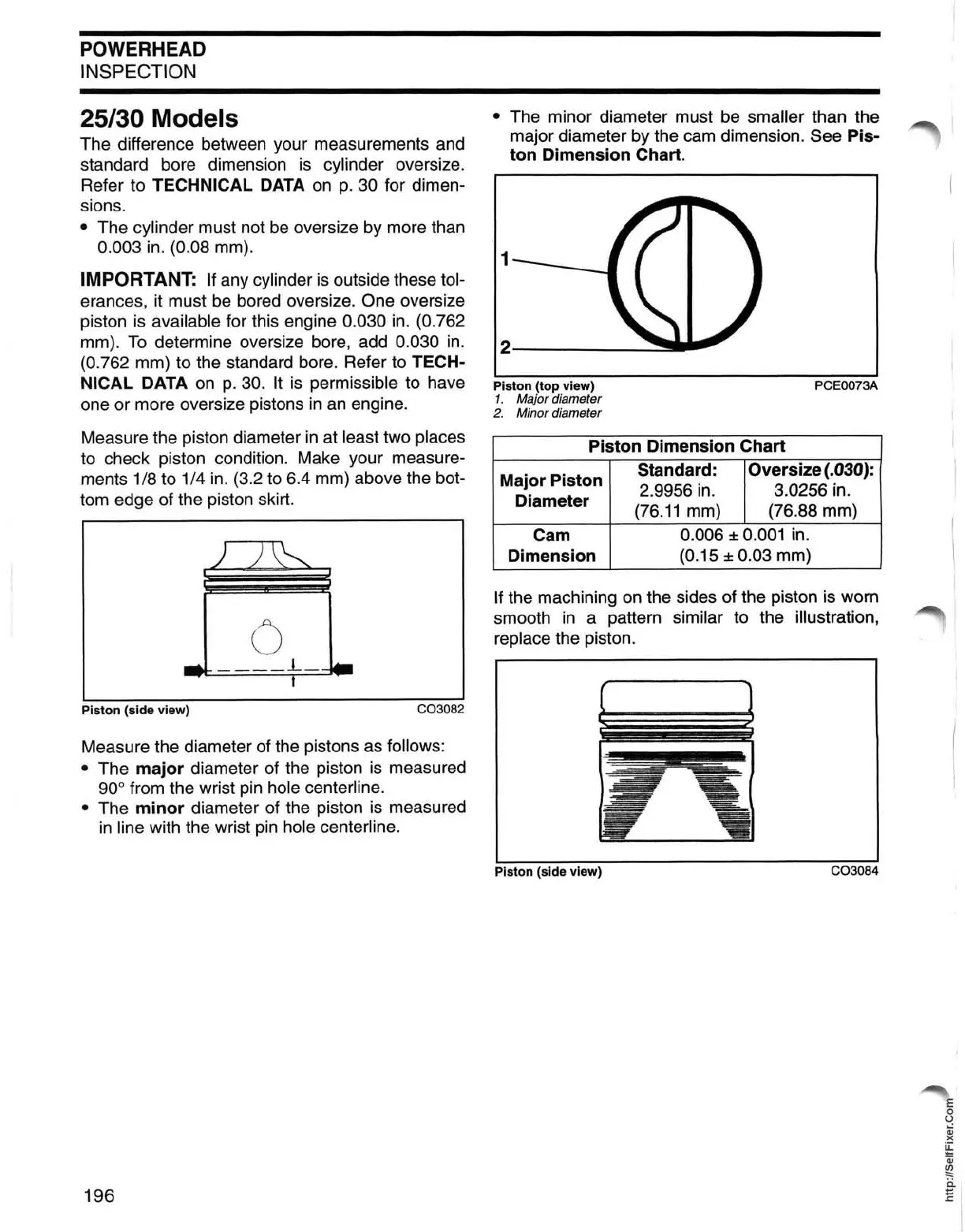

• The minor diameter must

be

smaller than the

major diameter by the

cam

dimension. See Pis-

ton Dimension Chart.

1

2----~

...

."

Piston

(top

view)

PCE0073A

1. Major diameter

2. Minor diameter

Piston Dimension Chart

Major Piston

Standard:

Oversize (.030):

2.9956

in

. 3.0256

in

.

Diameter

(76.11

mm)

(76.88 mm)

Cam

0.006 ± 0.001 in.

Dimension

(0

.

15

± 0.03 mm)

If the machining

on

the sides of the piston is worn

smooth

in

a pattern similar to the illustration,

replace the piston.

Piston (side view)

C03084

E

o

U

Qj

)(

~

Qj

~

~

I

Loading...

Loading...