POWERHEAD

INSPECTION

INSPECTION

All Models

Before any inspection process can begin, all inter-

nal components must

be

clean and free of excess

oil. Refer to CLEANING

on

p.

193.

Make a

visual inspection of all internal compo-

nents. Check for

unusual wear patterns, scuffing

or deterioration of

aluminum parts, heat-related

discoloration

of bearings or bearing surfaces, and

broken components.

Use a micrometer to measure the diameter of

each crankpin and main bearing

journal. Measure

the

lower main bearing journal if the bearing was

removed. Refer to

TECHNICAL DATA

on

p.

30

for

dimensions.

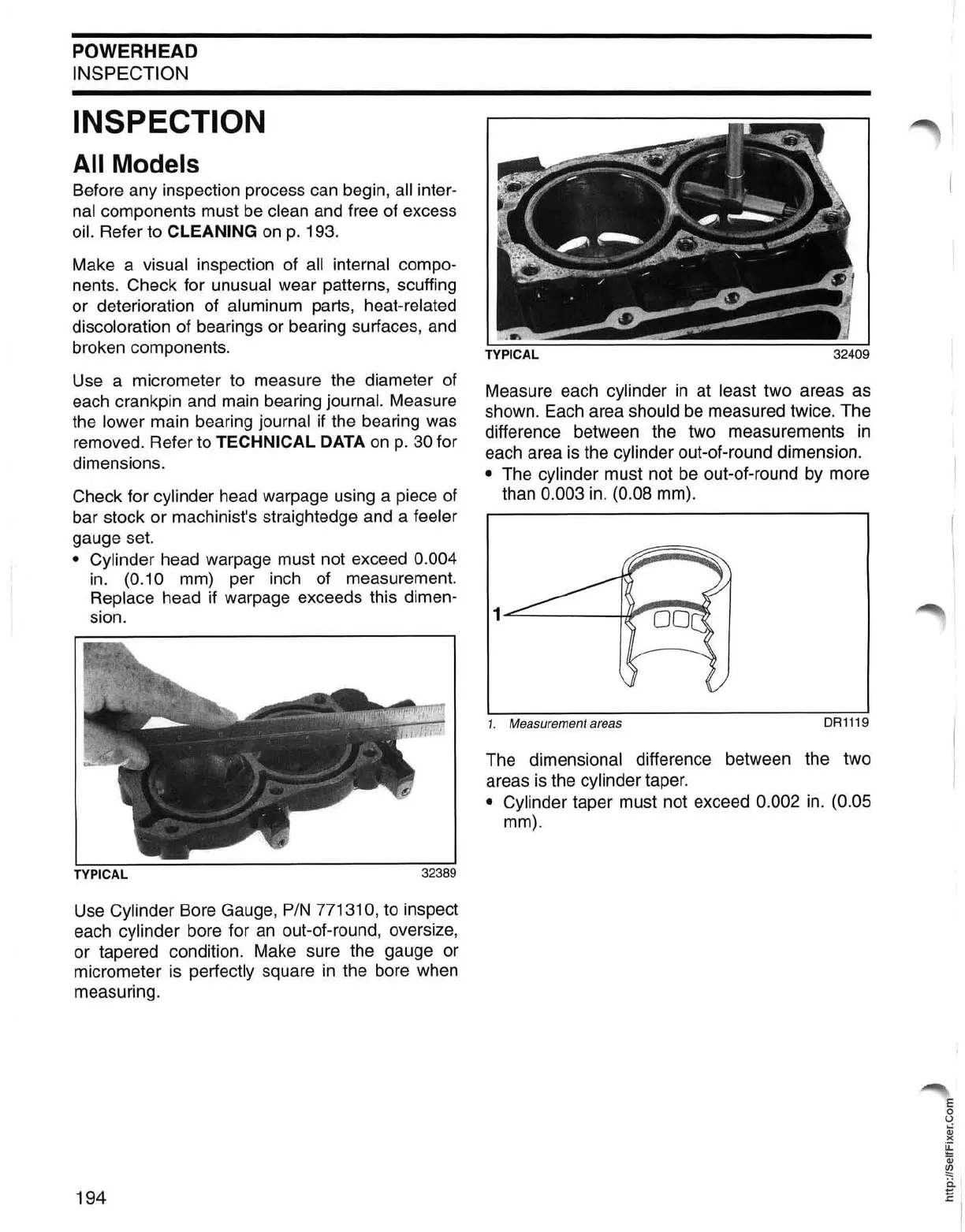

Check for

cylinder head warpage using a piece of

bar stock or machinist's straightedge and a

feeler

gauge set.

• Cylinder head warpage must not exceed 0.004

in

. (0.10 mm) per inch ot measurement.

Replace head it warpage exceeds this dimen-

sion.

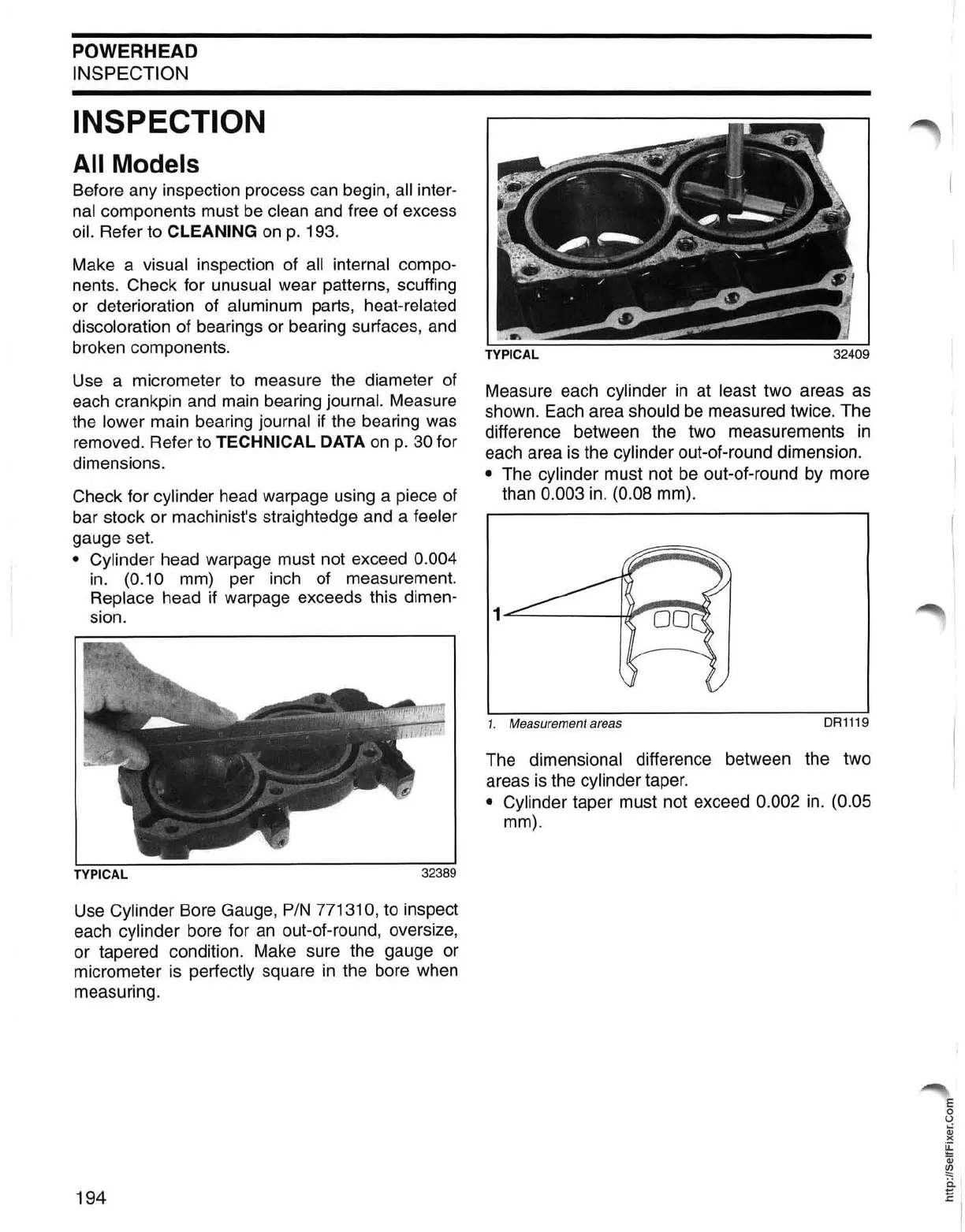

Use

Cylinder Bore Gauge,

PIN

771310, to inspect

each

cylinder bore for

an

out-ot-round, oversize,

or tapered condition. Make sure the gauge or

micrometer

is

perfectly square

in

the bore when

measuring.

194

Measure each cylinder

in

at least two areas as

shown. Each area

should

be

measured twice. The

difference between the two measurements

in

each area

is

the cylinder out-ot-round dimension.

• The cylinder must not

be

out-ot-round by more

than

0.003

in.

(0.08 mm).

1....:::;.....------i

'r-W'"

1.

Measurement areas

DR1119

The dimensional difference between the two

areas

is

the cylinder taper.

• Cylinder taper must not exceed 0.002

in.

(0.05

mm).

'E

o

U

Qj

)(

~

Qj

~

~

I

Loading...

Loading...