9.9/15 Models

The difference between your measurements and

standard bore dimension is

cylinder oversize.

Refer to

TECHNICAL

DATA

on

p.

30 for dimen-

sions.

• The cylinder must not be oversize by more than

0.002 in. (0.05 mm).

IMPORTANT: If any cylinder is outside these tol-

erances, it must be bored oversize. One oversize

piston

is

available for this engine 0.020 in. (0.508

mm).

To

determine oversize bore, add 0.020 in.

(0.508 mm) to the standard bore. Refer to TECH-

NICAL DATA

on

p.

30. It is permissible to have

one or more oversize pistons

in

an engine.

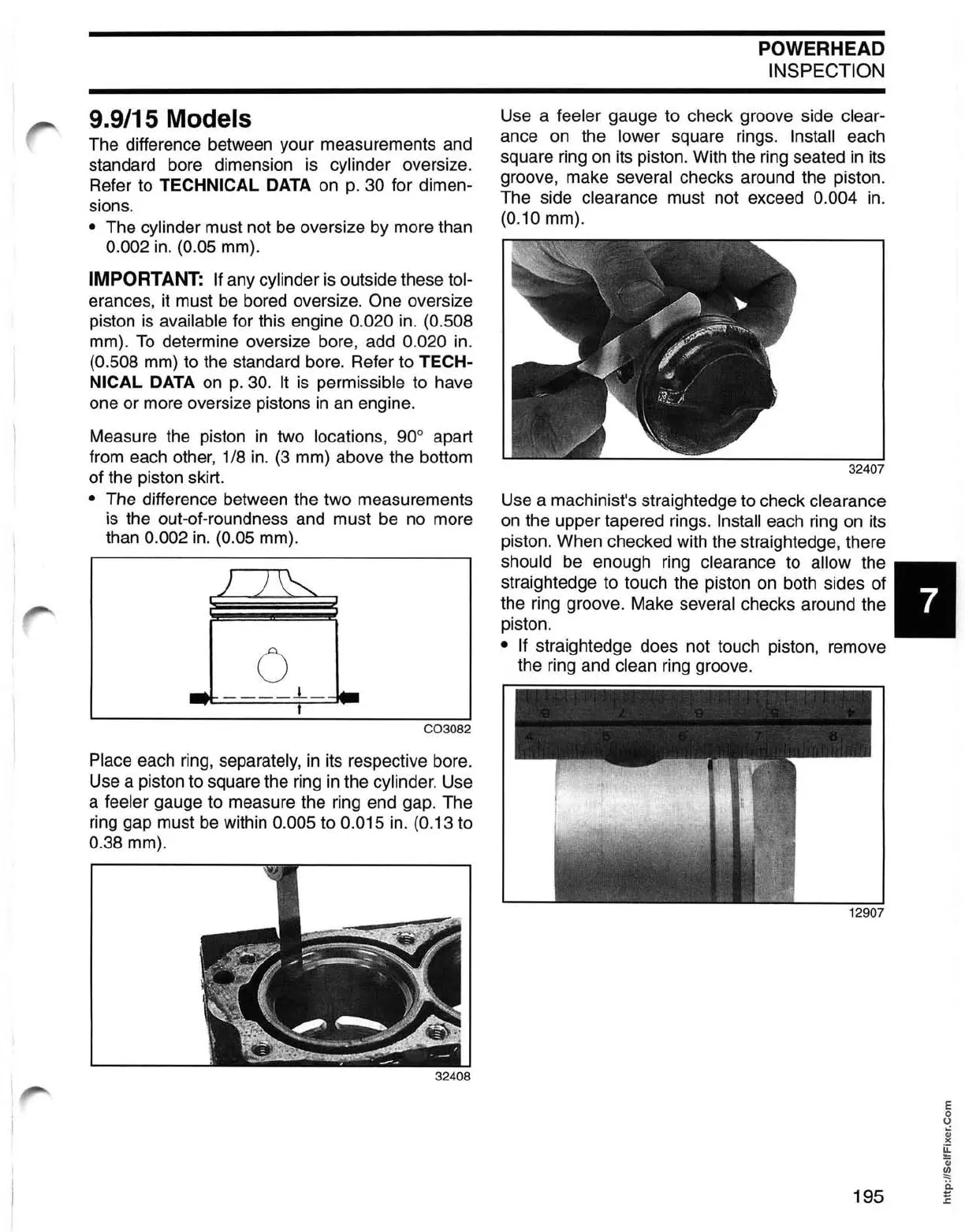

Measure the piston

in

two locations, 90

0

apart

from each other, 1/8 in. (3 mm) above the bottom

of

the piston skirt.

• The difference between the two measurements

is the out-of-roundness and must be no more

than

0.002

in.

(0.05 mm).

)

)

~'"

0

...

____

L

__

LiIIIIIII

t

C03082

Place each ring, separately,

in

its respective bore.

Use a piston to square the ring in the

cylinder. Use

a

feeler gauge to measure the ring end gap. The

ring gap must be within

0.005 to 0.015 in. (0.13 to

0.38 mm).

32408

POWERHEAD

INSPECTION

Use a feeler gauge to check groove side clear-

ance on the lower square rings. Install each

square ring on its piston. With the ring seated in its

groove, make

several checks around the piston.

The side

clearance must not exceed 0.004 in.

(0.10 mm).

32407

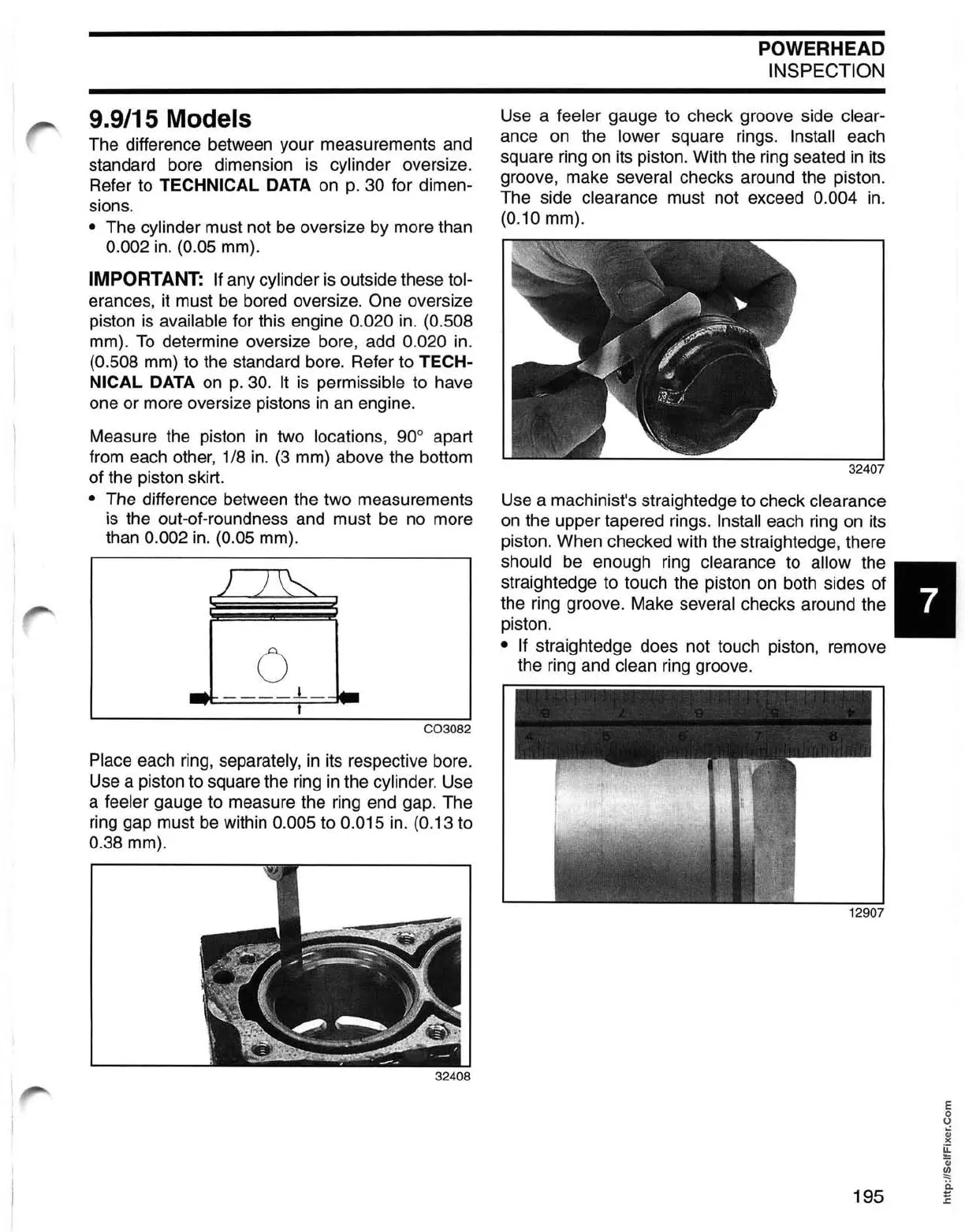

Use a machinist's straightedge to check clearance

on the upper tapered rings. Install each ring on its

piston. When checked with the straightedge, there

should be enough ring clearance to allow the •

straightedge to touch the piston on both sides of

the ring groove. Make

several checks around the

piston.

• If straightedge does not touch piston, remove

the ring and

clean ring groove.

12907

195

Loading...

Loading...