Function block library

7-122

SHB9300CRV EN 2.0

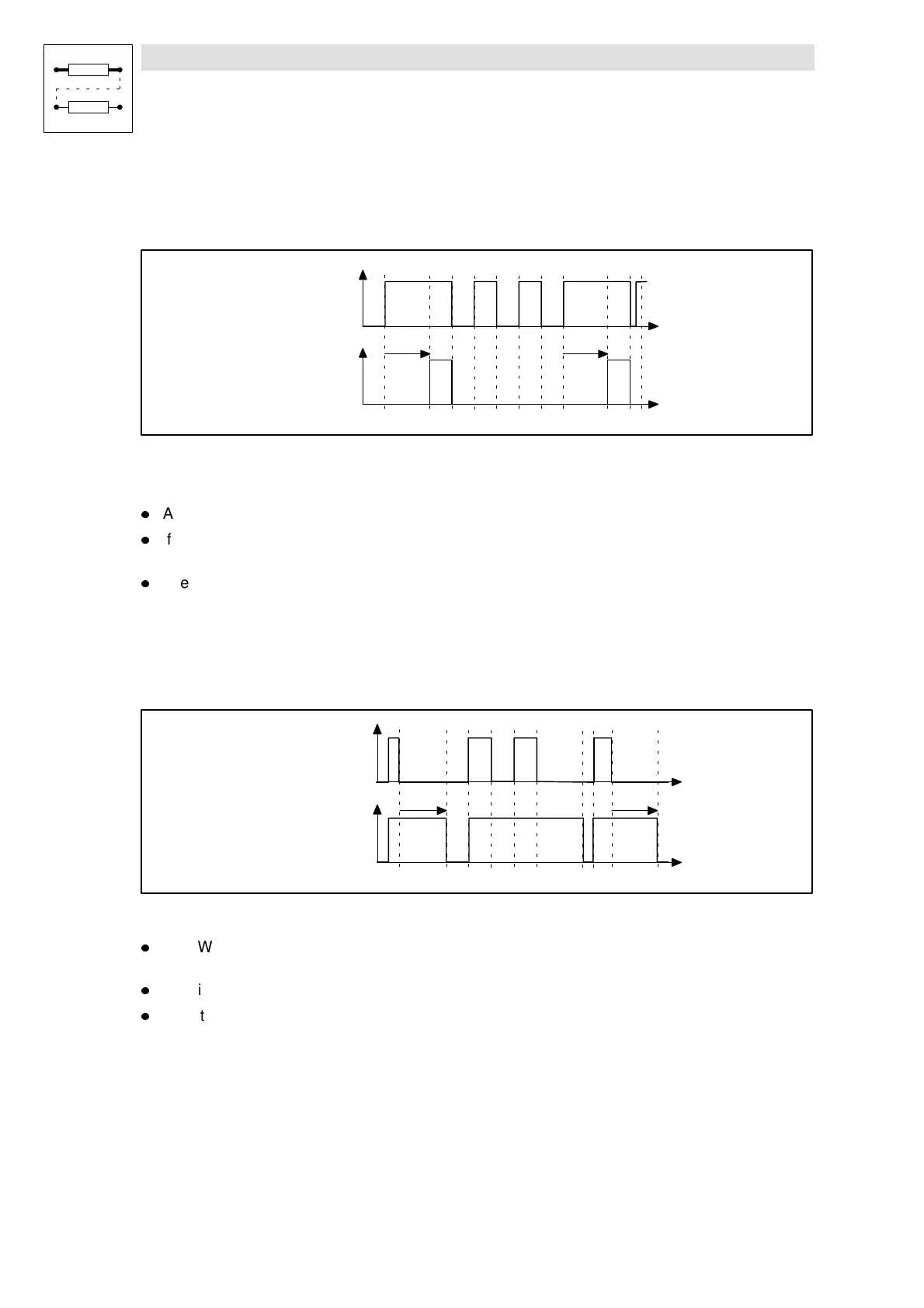

7.6.35.1 On-delay

If the on-delay is set, a signal change at the input DIGDELx-IN from LOW to HIGH is passed on to

the DIGDELx-OUT output after the delay time set under C0721 or C0726 has elapsed.

t

t

DIGDEL1-IN

DIGDEL1-OUT

C0721 C0721

Fig. 7-89 On-delay (DIGDEL1)

In this function, the time-element operates like a retriggerable monoflop:

l

A LOW-HIGH edge at the input DIGDELx-IN starts the time element.

l

If the delay time set under C0721 or C0726 has elapsed, the output DIGDELx-OUT is set to

HIGH.

l

The time element is reset and the output DIGDELx-OUT is set to LOW with a HIGH-LOW

edge at the input DIGDELx-IN.

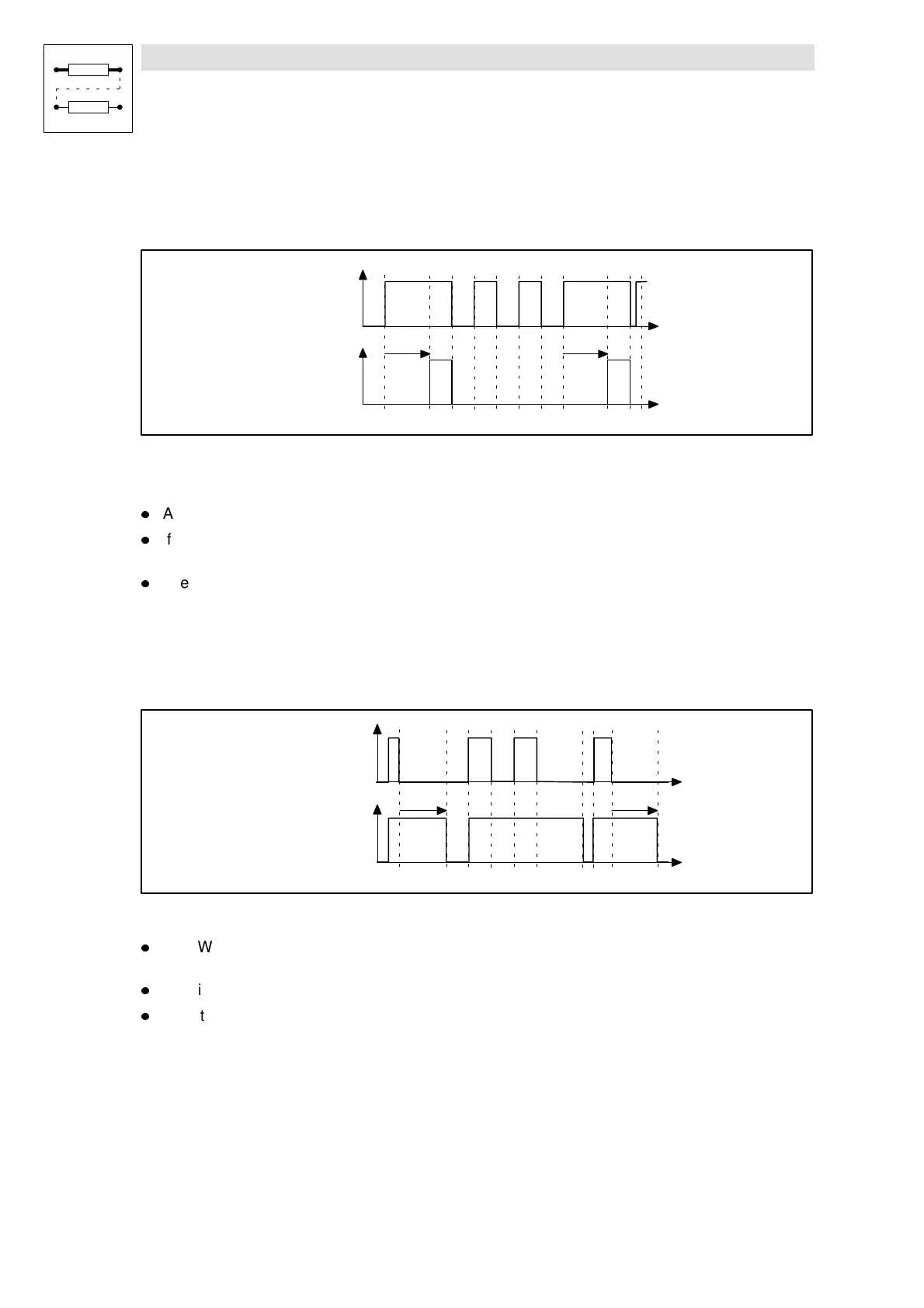

7.6.35.2 Dropout delay

A dropout delay causes a signal change at the input DIGDELx-IN from HIGH to LOW to be passed

on to the output DIGDELx-OUT if the delay time set under C0721 or C0726 has elapsed.

t

t

DIGDEL1-IN

DIGDEL1-OUT

C0721 C0721

Fig. 7-90 Dropout delay (DIGDEL1)

l

A LOW-HIGH edge at the input DIGDELx-IN causes the output DIGDELx-OUT to be set to

HIGH and the time element to be reset.

l

The time element is started with a HIGH-LOW edge at the input DIGDELx-IN.

l

After the delay time set under C0721 or C0726 has elapsed, the output DIGDELx-OUT is set

to LOW.

Loading...

Loading...