Function block library

7-242

SHB9300CRV EN 2.0

Synchronized stretching/compression of drive motion

Note!

This function is only valid for the cam drive, not for the master drive!

Synchronized stretching and compression is required for the following:

l

If master value and cam drive must run absolutely synchronously.

l

The factor must be changed during operation.

This function should be used if more than 8 profiles are required to change the cam drive travel.

The travel can be changed on-line via stretching and compression.

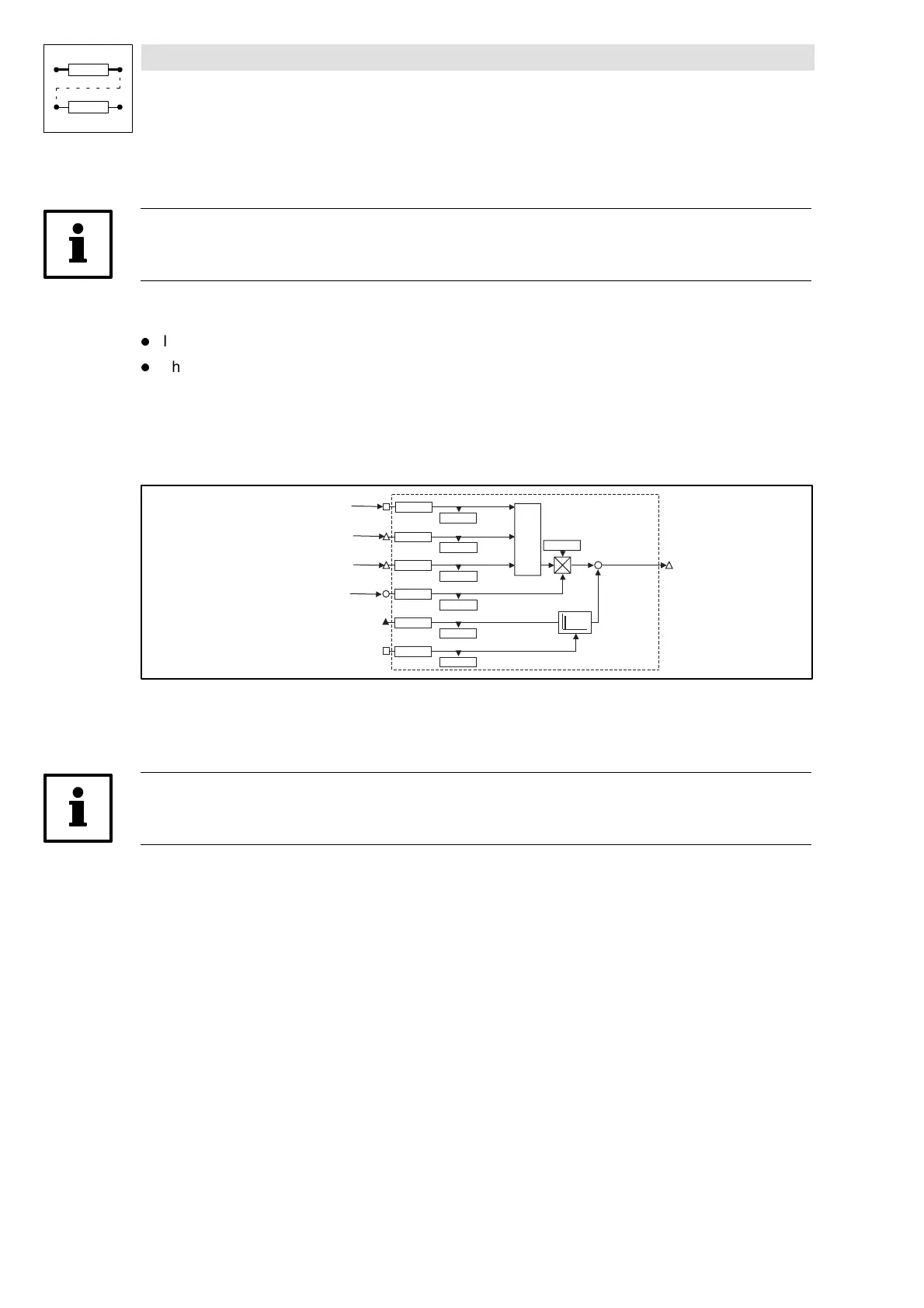

– Interconnection of function blocks

YSET1

YSET1-O UT

C 1357/1

YSET1-O FFS

C 1356/1

C 1353/1

YSET1-FACT

C 1352/1

C 1359/1

YSET1-IN

C 1358/1

+

C 1350

C 1355/1

YSET1-RESET

C 1354/1

C 1359/2

YSET1-IN-SYNCH

C 1358/2

CTRL

C 1355/2

YSET1-SYNCH

C 1354/2

CDATA-X0

CDATA-SYNCH

CDATA-NOUT

– Activate function

The function is only active if C1317 = 1.

The changeover is carried out during zero crossing of the profile.

Note!

Stretching/compression in X direction can be carried out via the input CDATA-XFACT.

7.6.79.2 Offset

It is possible to the X position by a constant value via input YSET-OFFS.

7.6.79.3 Direction reversal

There are two possibilities to inverse the direction of rotation:

1. Via code C1351/1.

2. Application of a stretching/compression factor

YSET-FACT = -100% (see also table above).

Loading...

Loading...