Function block library

7-236

SHB9300CRV EN 2.0

Function

l

Section adaptation of a welding bar (constant welding time)

l

Output of status signals

Stop!

The welding bar control can process only positively directed master phases (see codes 1444/1 and

1445/1). With master phases in negative direction the drive is not running!

7.6.78.1 Basics of welding bar control

General

The material is positioned by the feed drive. The welding bar is then lowered (closes) and welds the

material for the time preselected. After this time, the welding bar is opened and set to its waiting

position. This is the time required for one welding cycle; the next cycle will be started when new

material is applied.

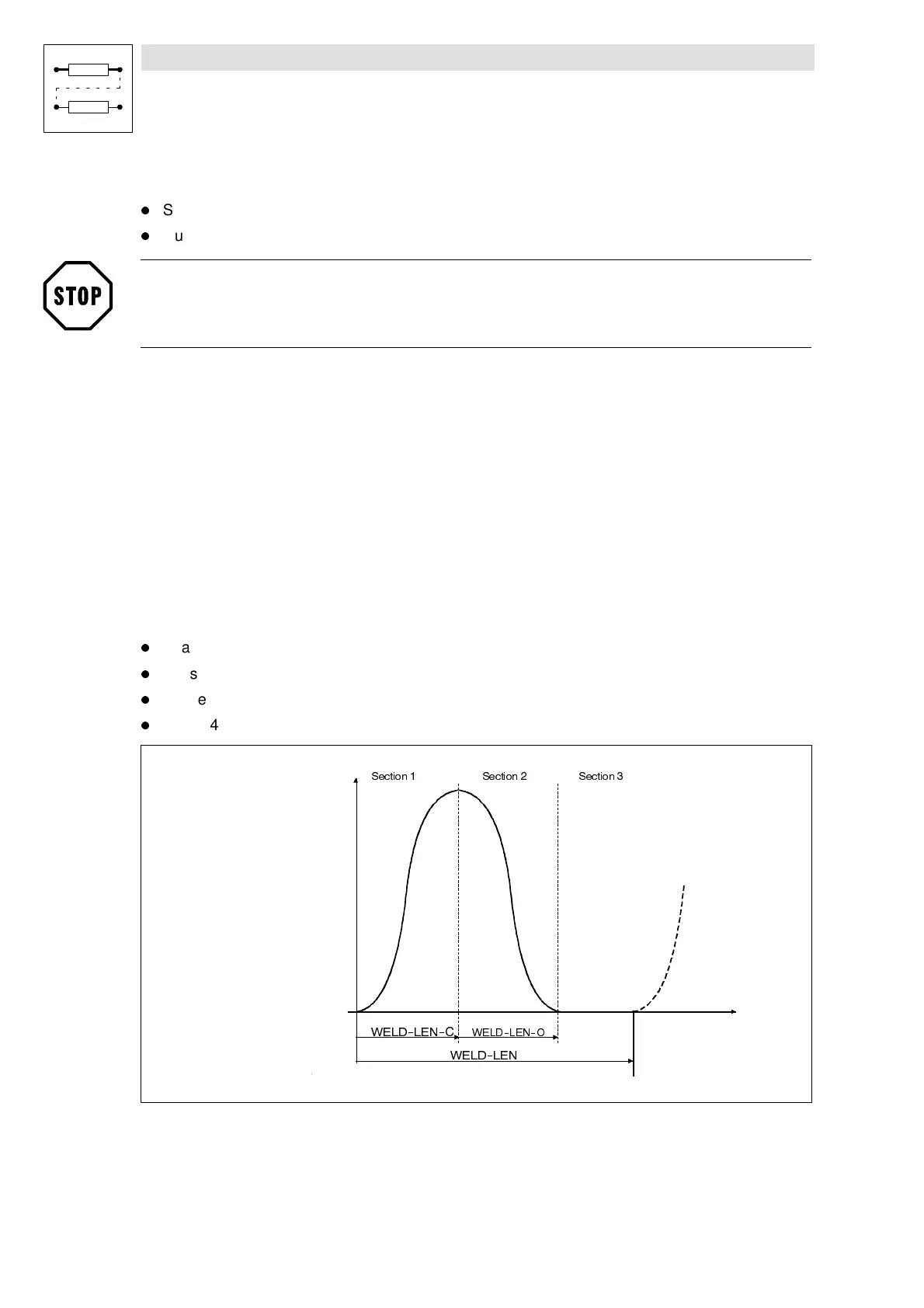

Generation of a cam profile for welding bar control

Because of the motion sequences described above a welding bar control can usually be divided in

3 or more sections (max. 5 for Lenze controllers).

Example for 3 sections:

l

Phase 1 = Welding bar moves down on material (section 1)

l

Phase 2 = Welding, drive remains in position

l

Phase 3 = Welding bar back to waiting position (section 2)

l

Phase 4 = Welding bar remains in waiting position (section 3 of profile).

Y-Pos

X-Pos

:(/'/(1

:(/'/(1&

:(/'/(12

6HFWLRQ 6HFWLRQ 6HFWLRQ

Loading...

Loading...