Function block library

7-185

SHB9300CRV EN 2.0

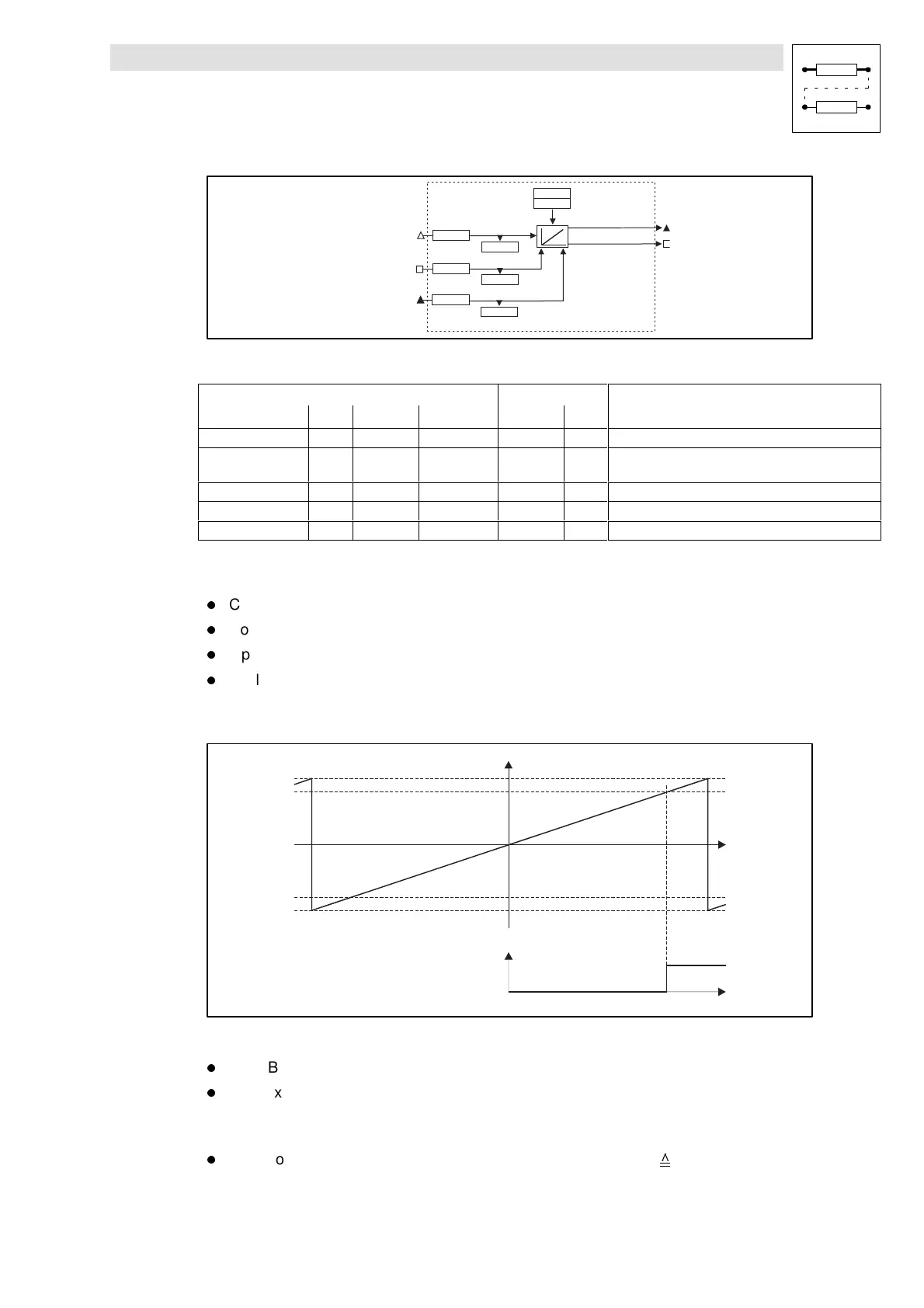

C 1157

PHINT3

PHINT3-O UT

PHINT3-IN

C 1158

PHINT3-LO AD

C 1153

C 1154

PHIN T3-STATUS

C 1150

C 1151

C 1159

PHINT3-SET

C 1155

Fig. 7-150 Phase inte grator (PHINT3)

S ignal

Source Note

Name Type DIS DIS format CFG List

PHINT3-IN phd C1157 dec [rpm] C1153 4 1 revolution = 65536 increments

PHINT3-LOAD d C1158 bin C1154 2 HIGH = sets the phase integrator to the input signal of

PHINT3-IN and PHINT3-STATUS = LOW

PHINT3-SET ph C1159 dec [inc] C1155 3

PHINT3-OUT ph - - - - 65536 inc = 1 encoder revolution, overflow is possible

PHINT3-STATUS d - - - - HIGH = overflow completed or distance covered

Function

l

Constant input value (PHINT1 and PHINT2)

l

Constant input value (PHINT3)

l

Input value with change of the sign (PHINT3)

l

Scaling of PHINTx-OUT

7.6.60.1 Constant input value (PHINT1 and PHINT2)

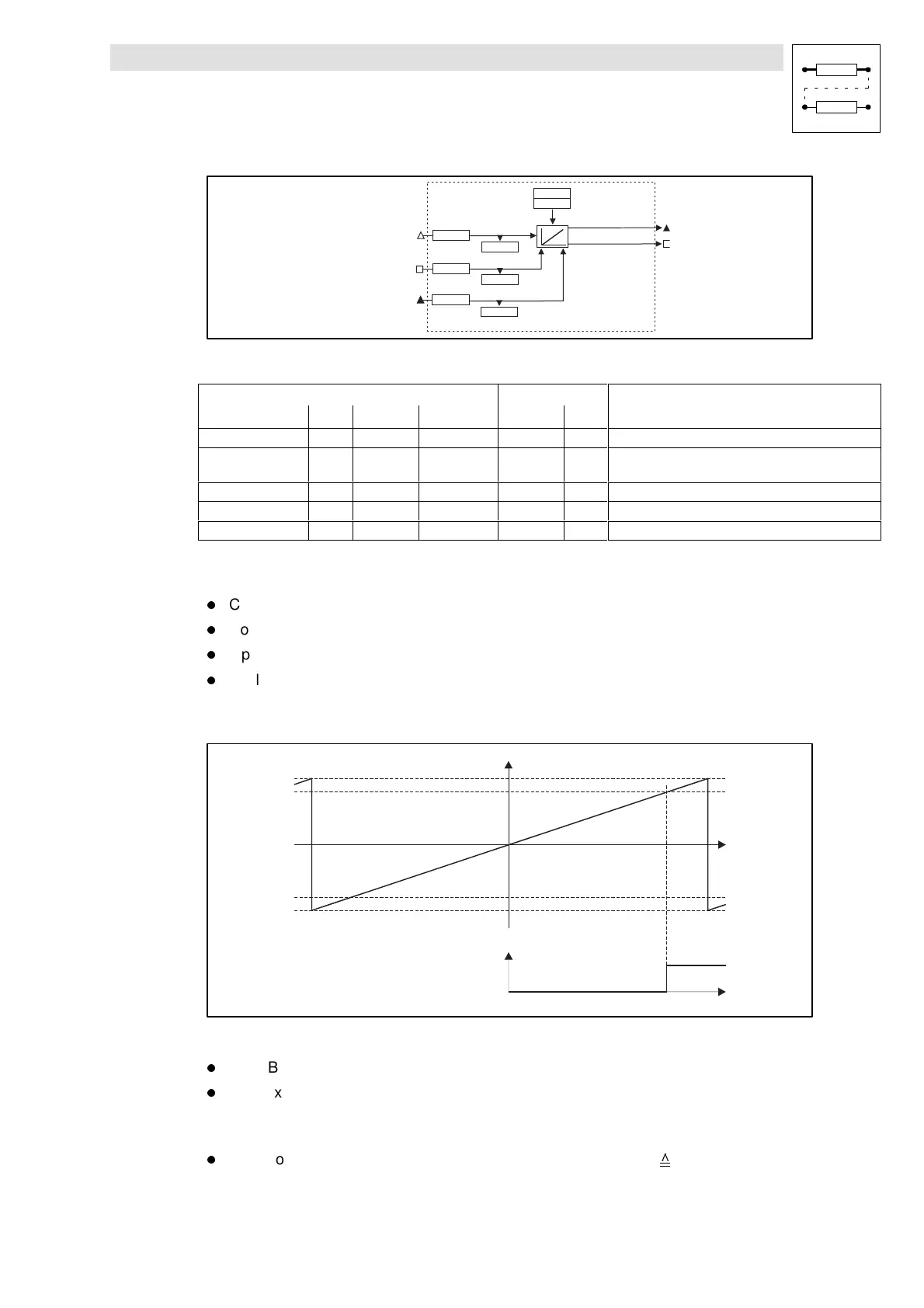

PHINTx-OUT

t

-32767 Umdr.

-C32000

+32000

+32767 Umdr.

PHINTx-FAIL

t

Fig. 7-151 Function of PHINTx with constant input value

l

The FB integrates speed or velocity values at PHINTx-IN to a phase (distance).

l

PHINTx-OUT outputs the count of the bipolar integrator.

– A positive value at PHINTx-IN increments the integrator (count is increased).

– A negative value at PHINTx-IN decrements the integrator (count is reduced).

l

If the count exceeds the value of +32767 encoder revolutions ( +2147483647 inc)

– an overflow results. The counting is continued at the value -32768.

Loading...

Loading...