Configuration

7-285

SHB9300CRV EN 2.0

l

The controller reads the terminals assigned to ”Select parameter” as binary code. The input

DCTRL-PAR*1 is the first input, the input DCTRL-PAR*2 is the second input. Input (e.g. E1 =

1st input, E2 = 2nd input).

– The signal must be constantly assigned to the terminals for at least 10 ms to ensure that the

parameter set to be loaded is correct.

– Terminal signals for the selection of parameter sets:

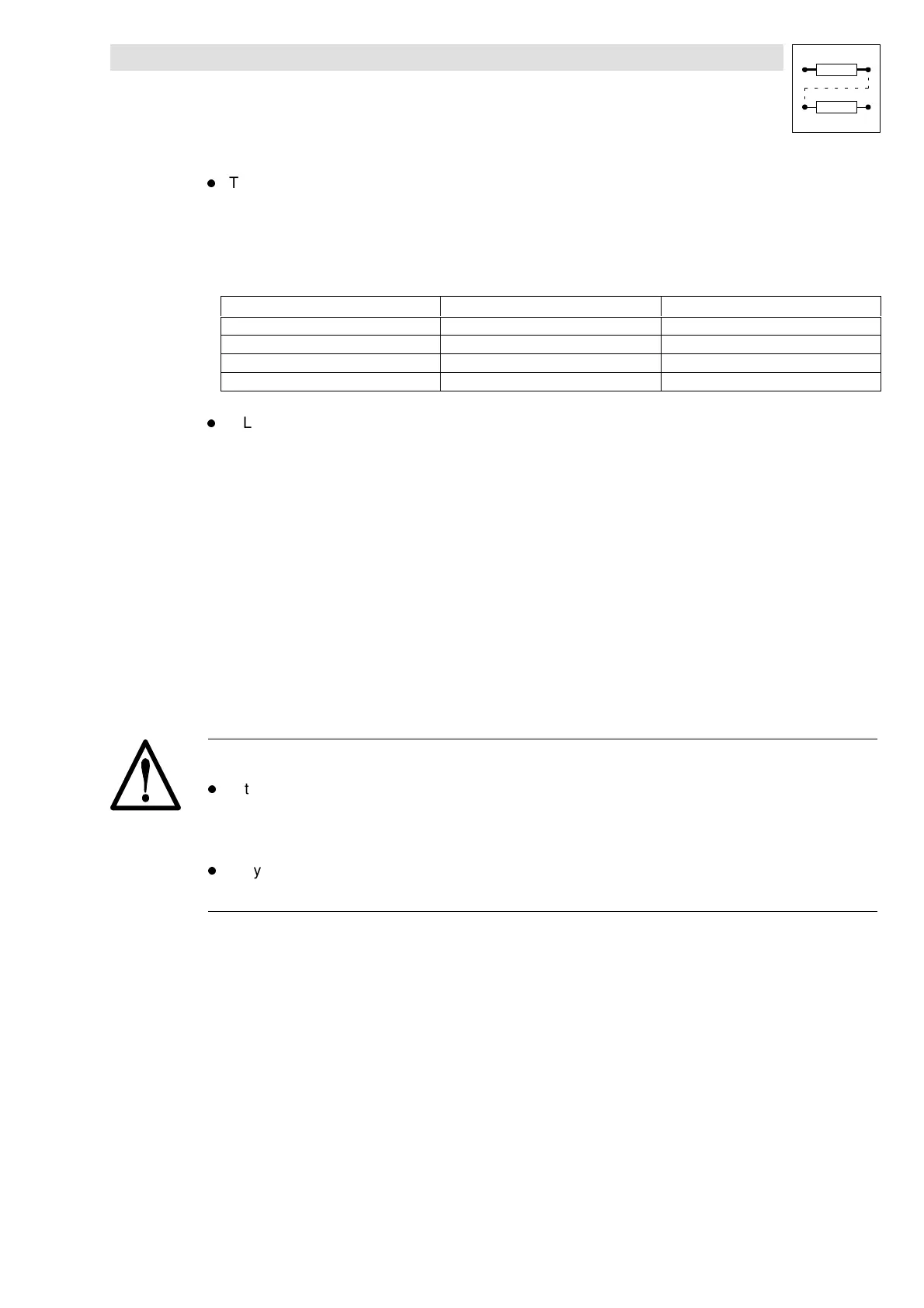

1st input (DCTRL-PAR*1) 2nd input (DCTRL-PAR*2)

Parameter set 1 LOW LOW

Parameter set 2 HIGH LOW

Parameter set 3 LOW HIGH

Parameter set 4 HIGH HIGH

l

A LOW-HIGH signal at the input ”Load parameter set” DCTRL-PAR-LOAD switches to the new

parameter set.

Procedure:

1. Control digital inputs which are assigned to the function ”Select parameter set”.

2. Inhibit the controller with X5/28 = LOW.

3. Activate a LOW-HIGH signal at the input ”Load parameter set”.

4. After loading:

– C0002 indicates the number of the loaded parameter set.

–RDYison.

5. Enable the controller with X5/28 = HIGH.

7.8.2.5 Parameter set transfer

(only possible with controller inhibit)

Warning!

l

After loading of a new parameter set the controller will be initialized again and behaves as if

the mains was switched on:

– System configurations and terminal assignment can be changed. Ensure, that your wiring

and drive configuration correspond to the settings of the parameter set.

l

Only use terminal X5/28 as source for the controller inhibit! Otherwise, the drive can start in an

uncontrolled way when changing to another parameter set.

Use the keypad to transfer complete parameter sets from one controller (e.g. controller 1)to another

controller (e.g. controller 2).

When copying from the controller to the keypad all parameter sets are copied and saved in the

keypad.

Procedure:

1. Plug the keypad in controller 1.

2. Inhibit the controller with X5/28 = LOW.

3. Save the last changes in the corresponding parameter set under C0003.

4. Use the arrow keys to change from the menus to the code level.

”Code” is displayed.

5. With z or y select C0003.

Loading...

Loading...