Function block library

7-127

SHB9300CRV EN 2.0

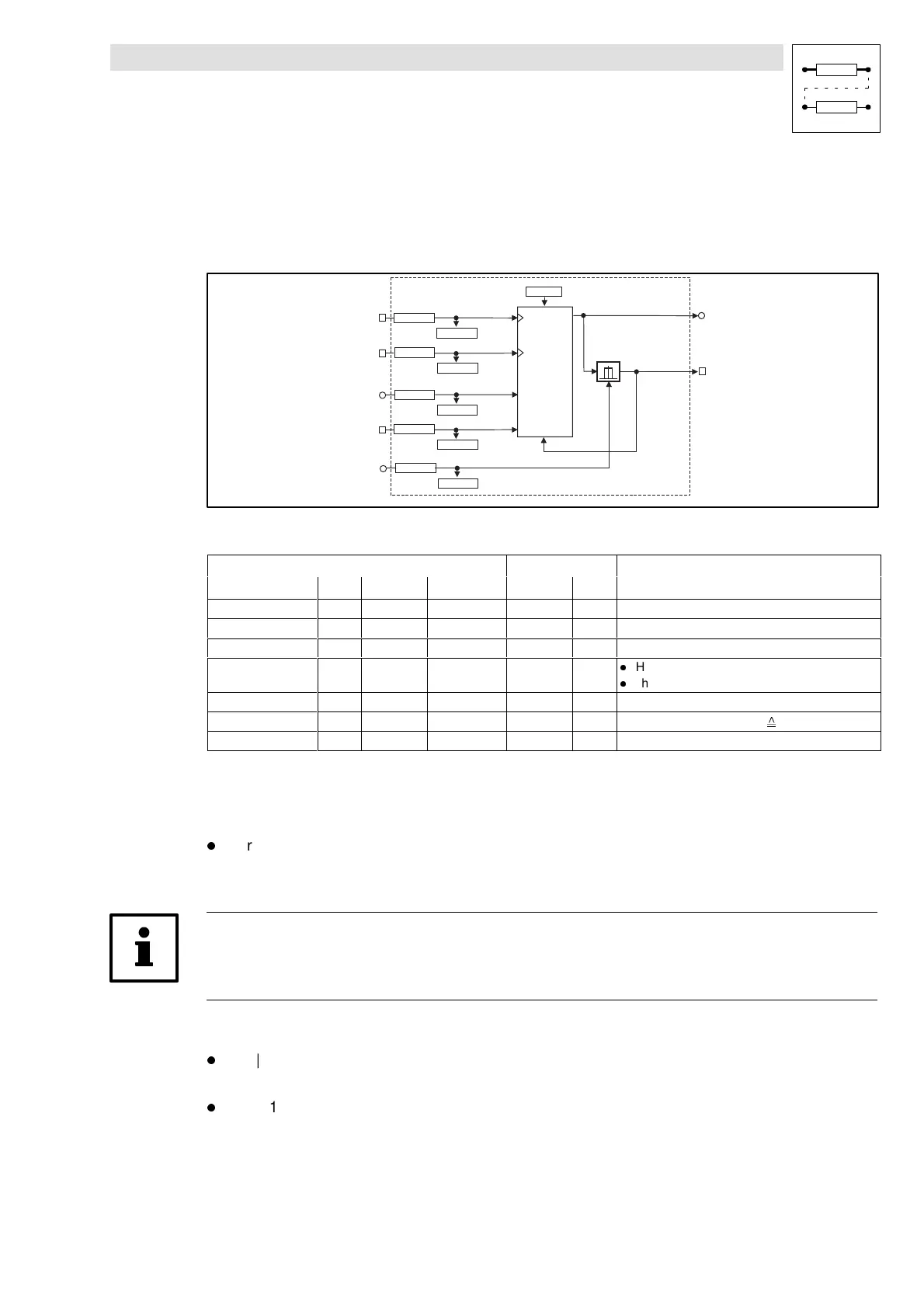

7.6.39 Free piece counter (FCNT)

Purpose

Digital up/down counter.

FCNT1-CLKUP

C 1102/1

FCNT1-CLKDW N

C 1102/2

C 1104/1

C 1104/2

FCNT1-LD-VAL

C 1101/1

C 1103/1

FCNT1-LOAD

C 1102/3

C 1104/3

FCNT1-OUT

FCNT1-EQUAL

C 1101/2

C 1103/2

FCNT1-CM P-VAL

C 1100

CTRL

FCNT1

Fig. 7-96 Free piece counter (FCNT1)

Signal

Source Note

Name Type DIS DIS format CFG List

FCNT1-CLKUP d C1104/1 bin C1102/1 2 LOW-HIGH edge = counts up by 1

FCNT1-CLKDWN d C1104/2 bin C1102/2 2 LOW-HIGH edge = counts down by 1

FCNT1-LD-VAL a C1103/1 dec C1101/1 1 Start value

FCNT1-LOAD d C1104/3 bin C1102/3 2

l

HIGH = Accept start value

l

The input has the highest priority

FCNT1-CMP-VAL a C1103/2 dec C1101/2 1 Comparison value

FCNT1-OUT a - - - - Counter limited to ±199.99 % ( ±32767)

FCNT1-EQUAL d - - - - HIGH = comparison value reached

Function

C1100 = 1

l

For | counter | | FCNT1-CMP-VAL | (comparison value):

– For 1 ms FCNT1-EQUAL = HIGH

– Resets the counter to the start value (FCNT1-LD-VAL)

Tip!

If thesignal isto beset for alonger time, e.g.when the output is requested by aPLC, you canextend

the signal with the TRANS function block.

C1100 = 2

l

For | counter | = | FCNT1-CMP-VAL | (comparison value):

– The counter stops

l

FCNT1-LOAD = HIGH resets the counter to the start value (FCNT1-LD-VAL)

Loading...

Loading...