DC−bus operation

Basic dimensioning

Cables

7

359

EDS94SPP101 EN 10.2

With different motor cable lengths, per axis at least 25 % of the longest cable must be

considered when calculating the total motor cable length.

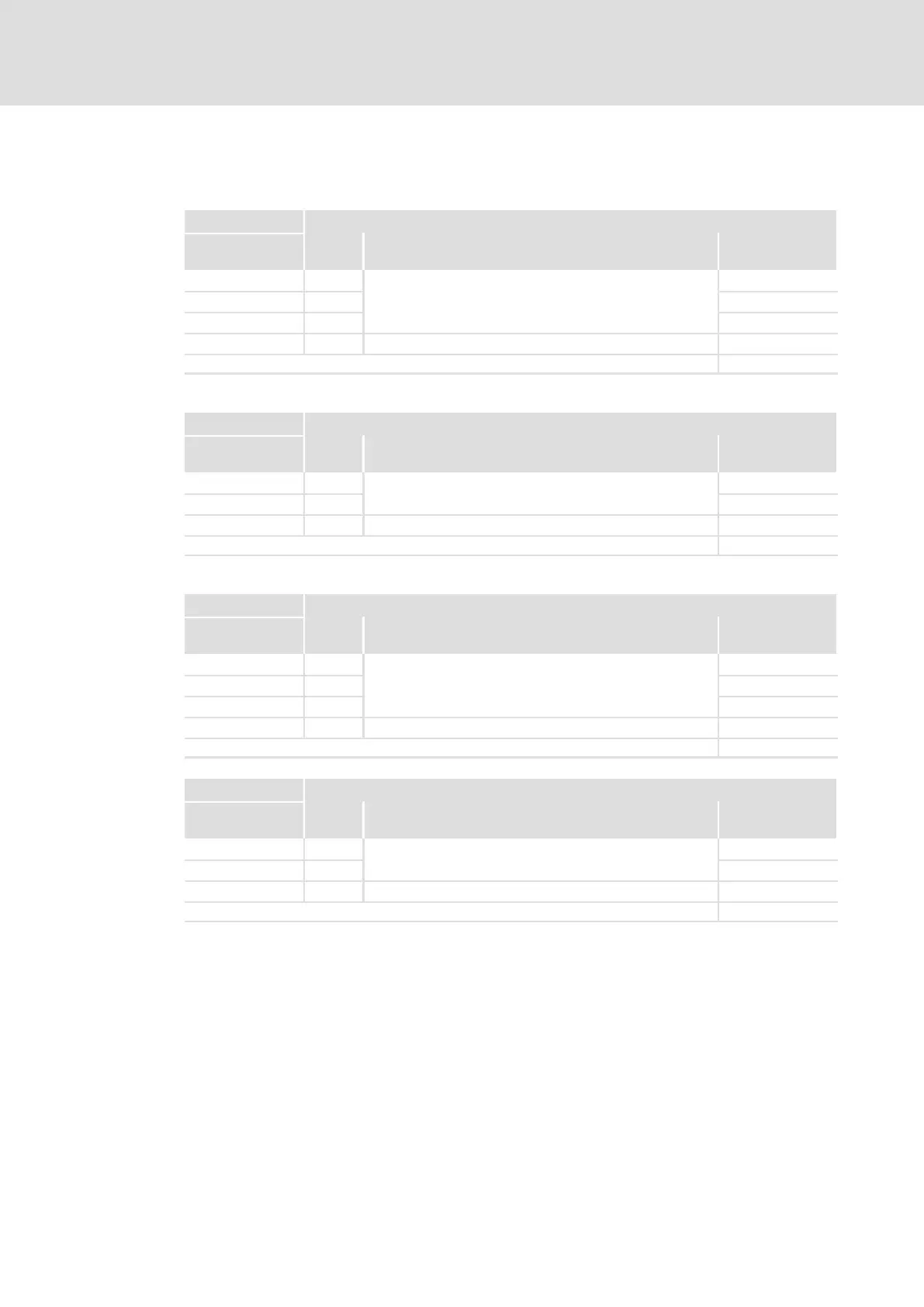

Example: 1 Motor cable length l

mot

[m]

Axis Actual

value

min. 25 % of the longest cable To be considered

16

0.25 * 20 = 5

6

2 ... 4 3 * 10 3 * 10

5 20 20

Total 56 max. permissible for 5 axes: < 60 56

EMC class C2 will be complied with.

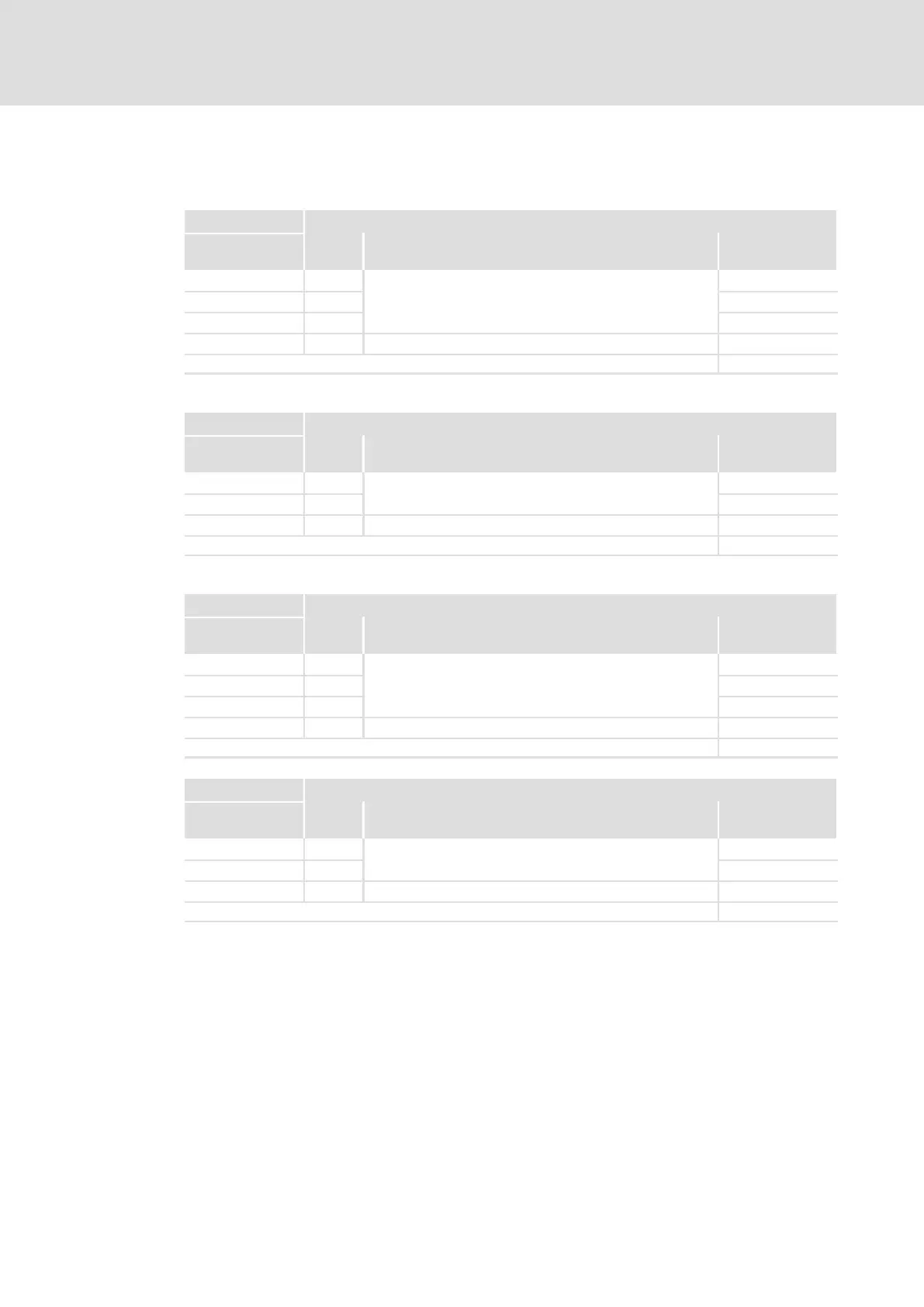

Example 2 Motor cable length l

mot

[m]

Axis Actual

value

min. 25 % of the longest cable To be considered

1 ... 4 4 * 5 0.25 * 40 = 10 4 * 10

5 40 40

Total 60 max. permissible for 5 axes: < 60 80

EMC class C2 will not be complied with.

Example: 3 Motor cable length l

mot

[m]

Axis Actual

value

min. 25 % of the longest cable To be considered

1 ... 3 3 * 100

0.25 * 100 = 25

3 * 100

4 50 50

5 ... 10 6 * 15 6 * 25

Total 410 max. permissible for 10 axes: < 500 500

EMC class C2 will be complied with.

Example: 4 Motor cable length l

mot

[m]

Axis Actual

value

min. 25 % of the longest cable To be considered

1 ... 4 4 * 100

0.25 * 100 = 25

4 * 100

5 ... 10 6 * 15 6 * 25

Total 490 max. permissible for 10 axes: < 500 550

EMC class C2 will not be complied with.

7.5.9 Cables

Select the cable cross−sections for the currents resulting from power P

DC100%

. Please

observe the standards and regulations applicable for the particular location and

application.

Loading...

Loading...