157

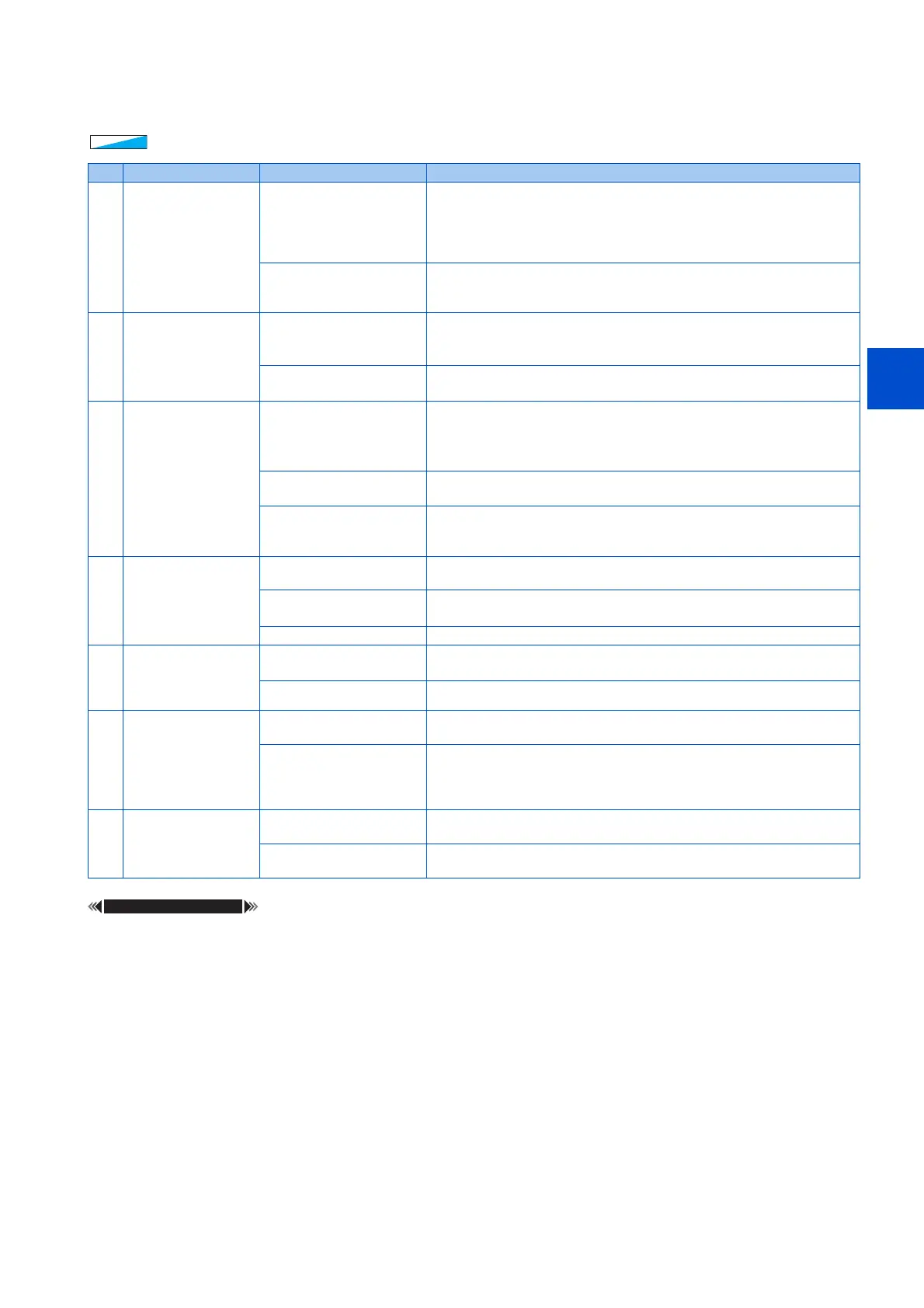

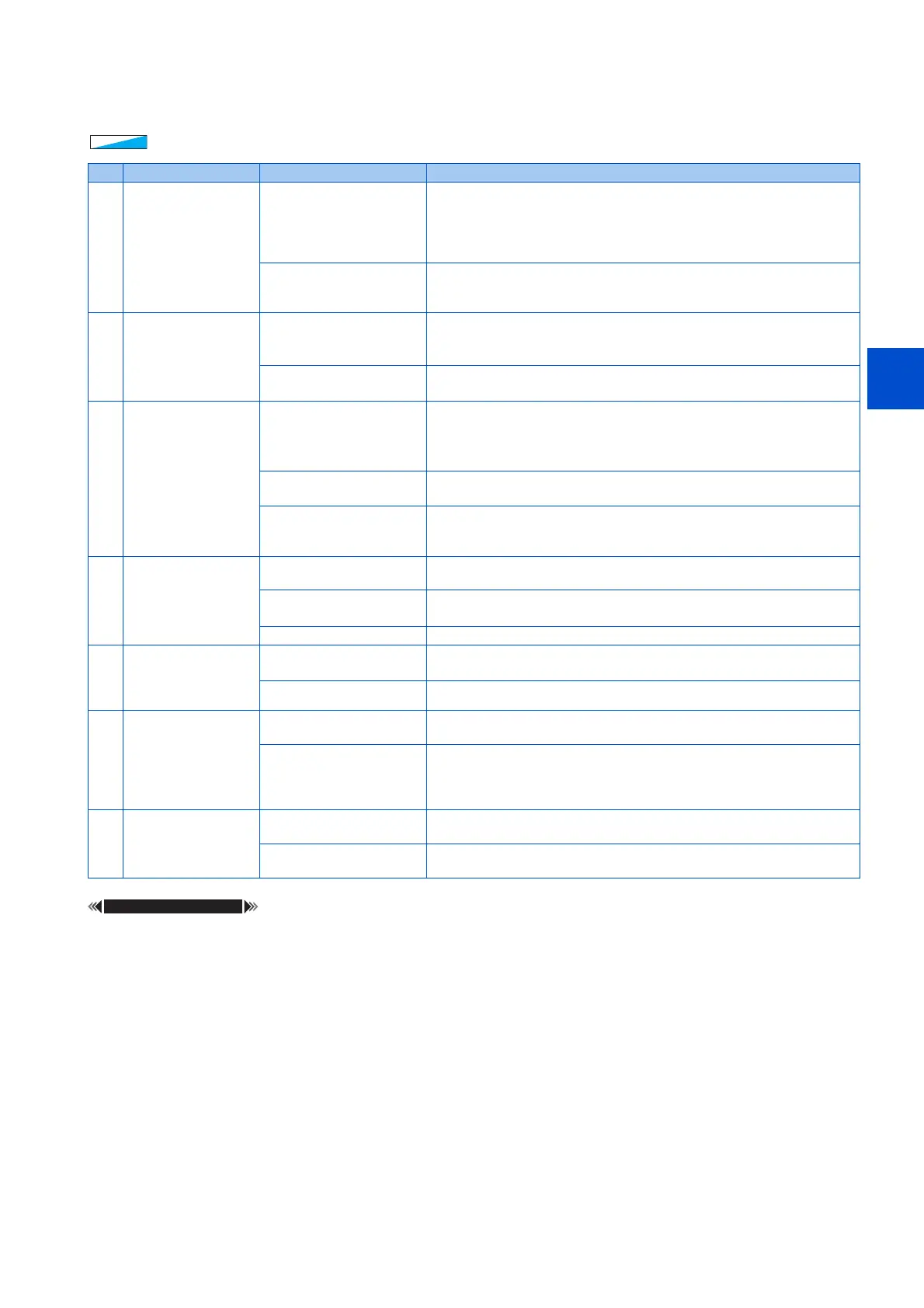

5. PARAMETERS

5.3 Speed control under PM motor control

3

4

5

5

5

6

7

8

9

10

5.3.3 Troubleshooting in the speed control

Pr.3 Base frequency, Pr.19 Base frequency voltage page 539

Pr.72 PWM frequency selection page 179

Pr.80 Motor capacity, Pr.81 Number of motor poles page 145

Pr.125 Terminal 2 frequency setting gain frequency, Pr.126 Terminal 4 frequency setting gain frequency page 328

Pr.822 Speed setting filter 1 page 326

No. Condition Cause Countermeasure

1 Motor does not run at

the correct speed.

(Command speed and

actual speed differ.)

Speed command from the

controller is different from

the actual speed.

The speed command is

affected by noise.

• Check that the speed command sent from the controller is correct. (Take

EMC measures.)

•Set Pr.72 PWM frequency selection lower.

The command speed and

the speed recognized by the

inverter are different.

• Adjust the bias and gain (Pr.125, Pr.126, Pr.902 to Pr.905, Pr.917,

Pr.918) of the speed command again.

2 The speed does not

accelerate to the

command speed.

Torque shortage.

The stall prevention

operation level is operating.

• Raise the stall prevention operation level.

• (Refer to page 257.)

• Increase the capacity.

Only P (proportional) control

is performed.

• Speed deviation occurs under P (proportional) control when the load is

heavy. Select PI control.

3 Motor speed

fluctuates.

Speed command varies. • Check that the speed command sent from the controller is correct. (Take

EMC measures.)

•Set Pr.72 lower.

•Set Pr.822 Speed setting filter 1 higher. (page 326)

Torque shortage. • Raise the stall prevention operation level.

• (Refer to page 257.)

Speed control gain is not

suitable for the machine.

(Resonance occurs.)

• Adjust Pr.820 Speed control P gain 1 and Pr.821 Speed control integral

time 1.

4 Hunting (vibration or

acoustic noise) occurs

in the motor or the

machine.

Speed control gain is too

high.

•Set Pr.820 lower and Pr.821 higher.

Torque control gain is too

high.

•Set Pr.824 Torque control P gain 1 (current loop proportional gain)

lower.

Motor wiring is incorrect. • Check the wiring.

5 Acceleration/

deceleration time is

different from the

setting.

Torque shortage. • Raise the stall prevention operation level.

• (Refer to page 257.)

Load inertia is too high. • Set acceleration/deceleration time suitable for the load.

6 Machine movement is

unstable.

Speed control gain is not

suitable for the machine.

• Adjust Pr.820 and Pr.821.

Response is slow because

of the inverter's

acceleration/deceleration

time setting.

• Set the optimum acceleration/deceleration time.

7 Rotation ripple occurs

during the low-

speed

operation.

High carrier frequency is

affecting the motor rotation.

•Set Pr.72 lower.

Speed control gain is too

low.

•Set Pr.820 higher.

Parametersreferredto

Loading...

Loading...