56

2. INSTALLATION AND WIRING

2.6 Control circuit

2.6.3 Wiring of control circuit

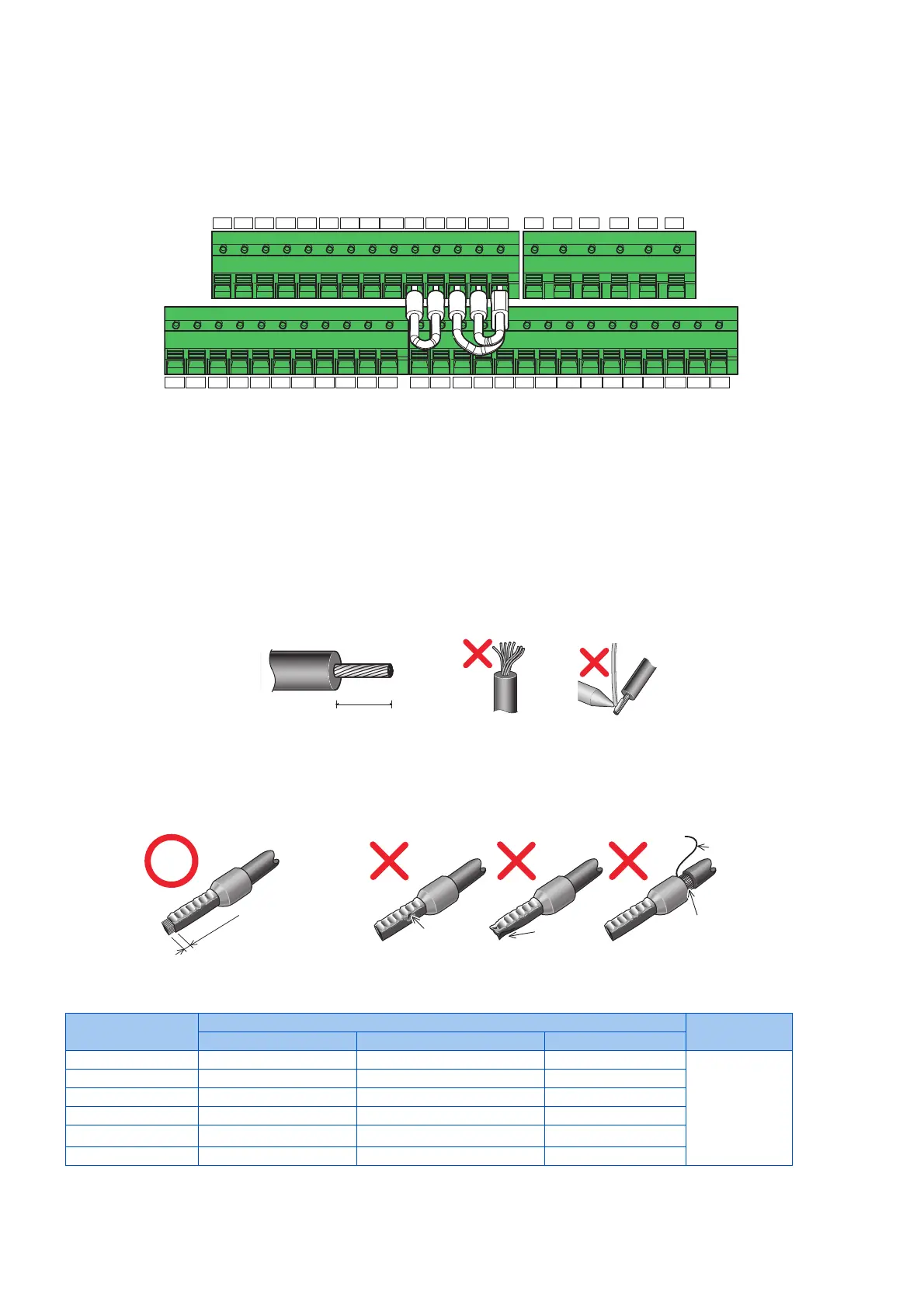

Control circuit terminal layout

• Recommended cable gauge: 0.3 to 0.75 mm

2

*1 This terminal operates as the terminal CA.

Wiring method

Power supply connection

Use crimp terminals and stripped wire for the control circuit wiring. For single wire, the stripped wire can be used without crimp

terminal.

Connect the end of wires (crimp terminal or stranded wire) to the terminal block.

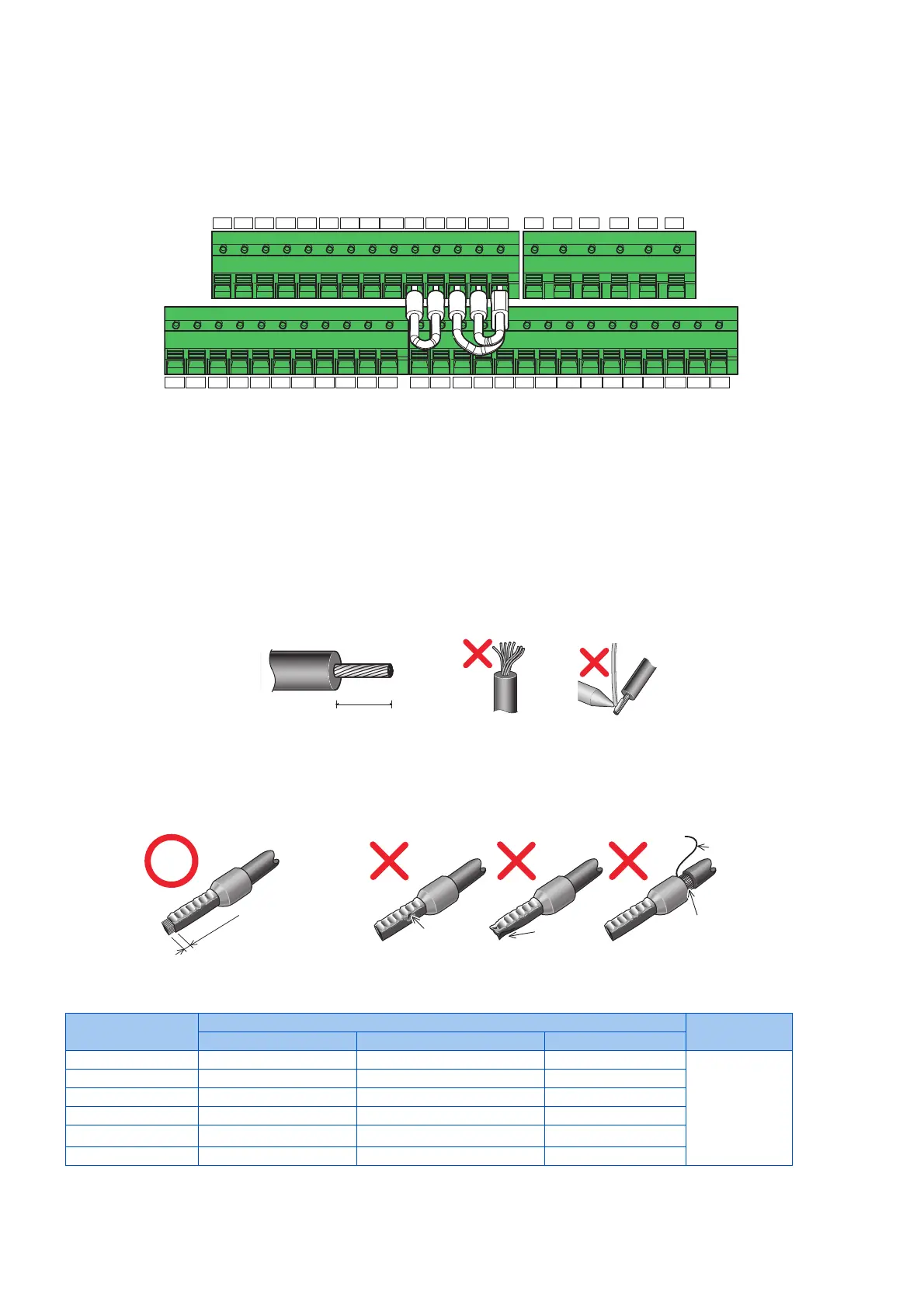

1. Strip the signal wires as shown below. If too much of the wire is stripped, a short circuit may occur with neighboring

wires. If not enough of the wire is stripped, wires may become loose and fall out. Twist the stripped end of wires to

prevent them from fraying. Do not solder it.

2. Use appropriate crimp terminals (ferrules, blade terminals, etc.). Insert wires to the crimp terminal, and check that

the wires come out for about 0 to 0.5 mm from a sleeve. Check the condition of the crimp terminals after crimping.

Do not use the crimp terminals of which the crimping is inappropriate, or the face is damaged.

• Crimp terminals commercially available (as of October 2020)

Phoenix Contact Co., Ltd.

*1 A ferrule terminal with an insulation sleeve compatible with the MTW wire which has a thick wire insulation.

*2 Applicable to the terminals A1, B1, C1, A2, B2, and C2.

Wire strip length

Wire gauge (mm

2

) Ferrule part No. Crimping tool

model No.

With insulation sleeve Without insulation sleeve For UL wire

*1

0.3 AI 0,34-10TQ — — CRIMPFOX 6

0.5 AI 0,5-10WH — AI 0,5-10WH-GB

0.75 AI 0,75-10GY A 0,75-10 AI 0,75-10GY-GB

1 AI 1-10RD A 1-10 AI 1-10RD/1000GB

1.25, 1.5 AI 1,5-10BK A 1,5-10

AI 1,5-10BK/1000GB

*2

0.75 (for two wires) AI-TWIN 2 0,75-10GY — —

AM

2 5 4 1 F/C

+24

SD SD S1 S2 PC A1 B1 C1 A2 B2 C2SICSo

SOC

5 10E 10 SE SE SU

RUN

IPF OL FU PC RL RM RH RT AU SD SD CSSTP

MRS RES

STF STR

JOG

∗1

Crumpled tip

Wires are not inserted

into the sleeve

Unstranded

wires

Damaged

WireWire

SleeveSleeve

0 to 0.5 mm0 to 0.5 mm

Loading...

Loading...