168

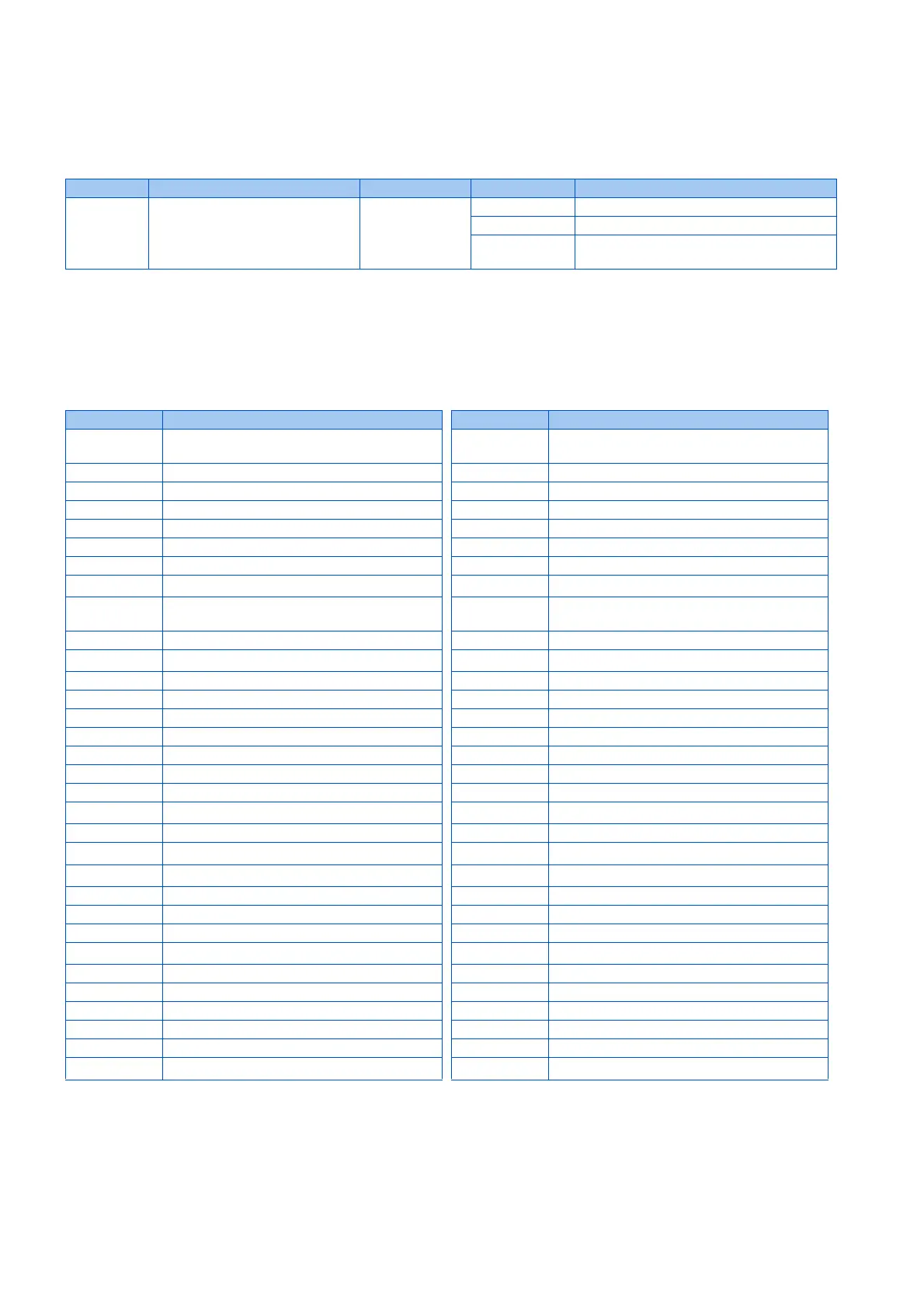

5. PARAMETERS

5.4 (E) Environment setting parameters

5.4.9 Parameter write selection

Whether to enable the writing to various parameters or not can be selected. Use this function to prevent parameter values from

being rewritten by misoperation.

• Pr.77 can be set at any time regardless of the operation mode or operation status. (Setting through communication is

unavailable.)

Writing parameters only during stop (Pr.77 = "0" initial value)

• Parameters can be written only during a stop in the PU operation mode.

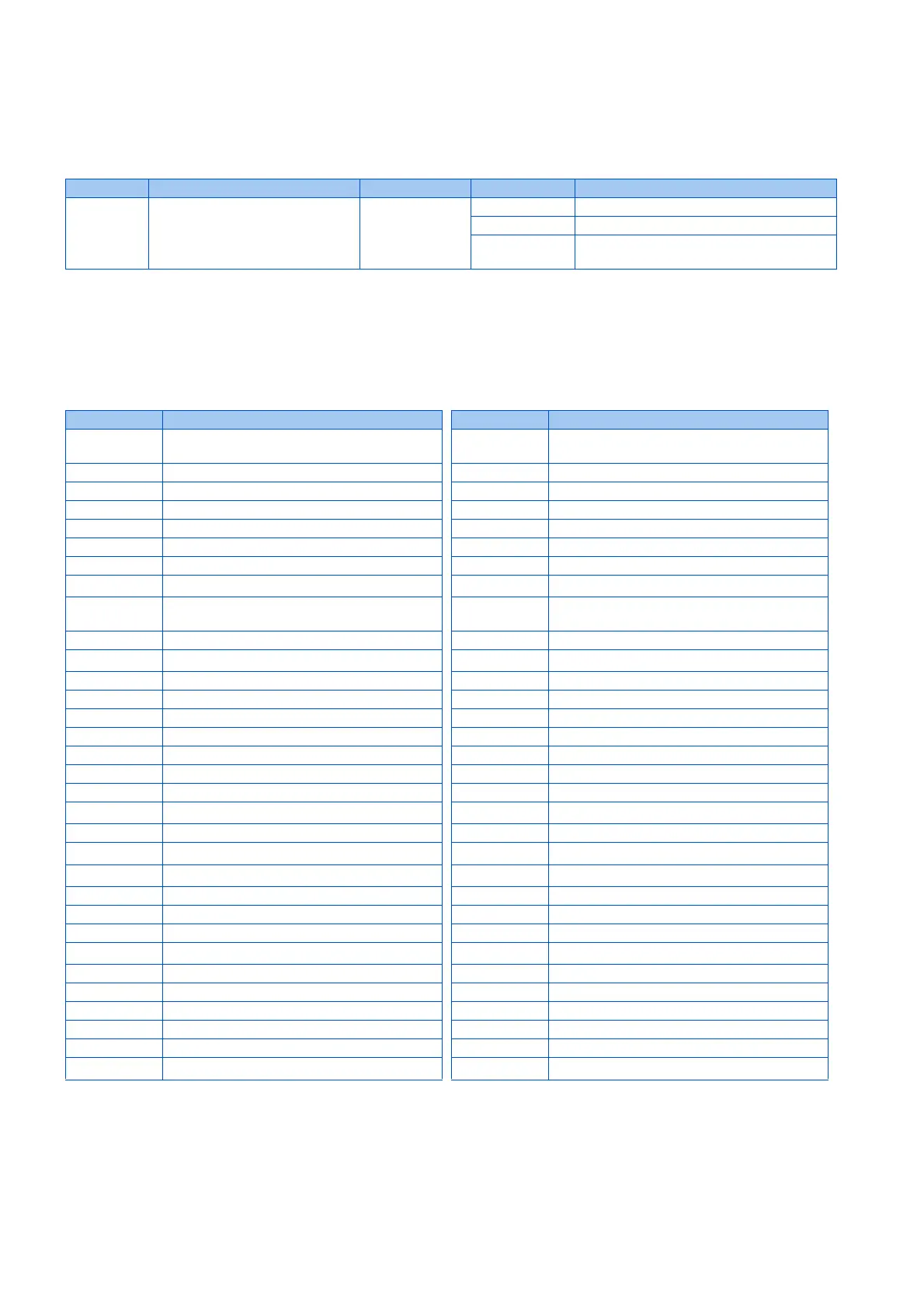

• The following parameters can always be written regardless of the operation mode or operation status.

*1 Writing during operation is enabled in PU operation mode, but disabled in External operation mode.

*2 Writing during operation is disabled. To change the parameter setting value, stop the operation.

Pr. Name Initial value Setting range Description

77

E400

Parameter write selection 0 0 Writing is enabled only during stop.

1 Parameter writing is disabled.

2 Parameter writing is enabled in any operation

mode regardless of the operation status.

Pr. Name Pr. Name

4 to 6 (Multi-speed setting high-speed, middle-speed,

low-speed)

551

*2

PU mode operation command source selection

22 Stall prevention operation level 555 to 557 (Current average value monitor)

24 to 27 (Multi-speed setting speed 4 to speed 7) 656 to 659 (Analog remote output)

52 Operation panel main monitor selection 663 Control circuit temperature signal output level

54 CA terminal function selection 675 User parameter auto storage function selection

55 Frequency monitoring reference 755 to 758 (Second PID control)

56 Current monitoring reference 759 PID unit selection

72

*1

PWM frequency selection 774 to 776 (PU/DU monitor selection)

75 Reset selection/disconnected PU detection/PU

stop selection

866 Torque monitoring reference

77 Parameter write selection 888, 889 (Free parameter)

79

*2

Operation mode selection 891 to 899 (Energy saving monitor)

129 PID proportional band 900 CA terminal calibration

130 PID integral time 901 AM terminal calibration

133 PID action set point 930 Current output bias signal

134 PID differential time 930 Current output bias current

158 AM terminal function selection 931 Current output gain signal

160 User group read selection 931 Current output gain current

232 to 239 (Multi-speed setting speed 8 to speed 15) 990 PU buzzer control

240

*1

Soft-PWM operation selection 991 PU contrast adjustment

241 Analog input display unit switchover 997 Fault initiation

268 Monitor decimal digits selection

998

*2

PM parameter initialization

290 Monitor negative output selection

999

*2

Automatic parameter setting

296, 297 (Password setting) 1000 Direct setting selection

306 Analog output signal selection 1006 Clock (year)

310 Analog meter voltage output selection 1007 Clock (month, day)

340

*2

Communication startup mode selection 1008 Clock (hour, minute)

345, 346 (DeviceNet communication) 1019 Analog meter voltage negative output selection

416, 417 (PLC function) 1142 Second PID unit selection

434, 435 (CC-Link communication) 1150 to 1199 (PLC function user parameters)

496, 497 (Remote output) 1211 to 1219 (PID gain tuning)

498 PLC function flash memory clear 1460 to 1466 (PID multistage set points 1 to 7)

550

*2

NET mode operation command source selection 1480 to 1485 (Load characteristics fault detection)

Loading...

Loading...