622

9. APPENDIX

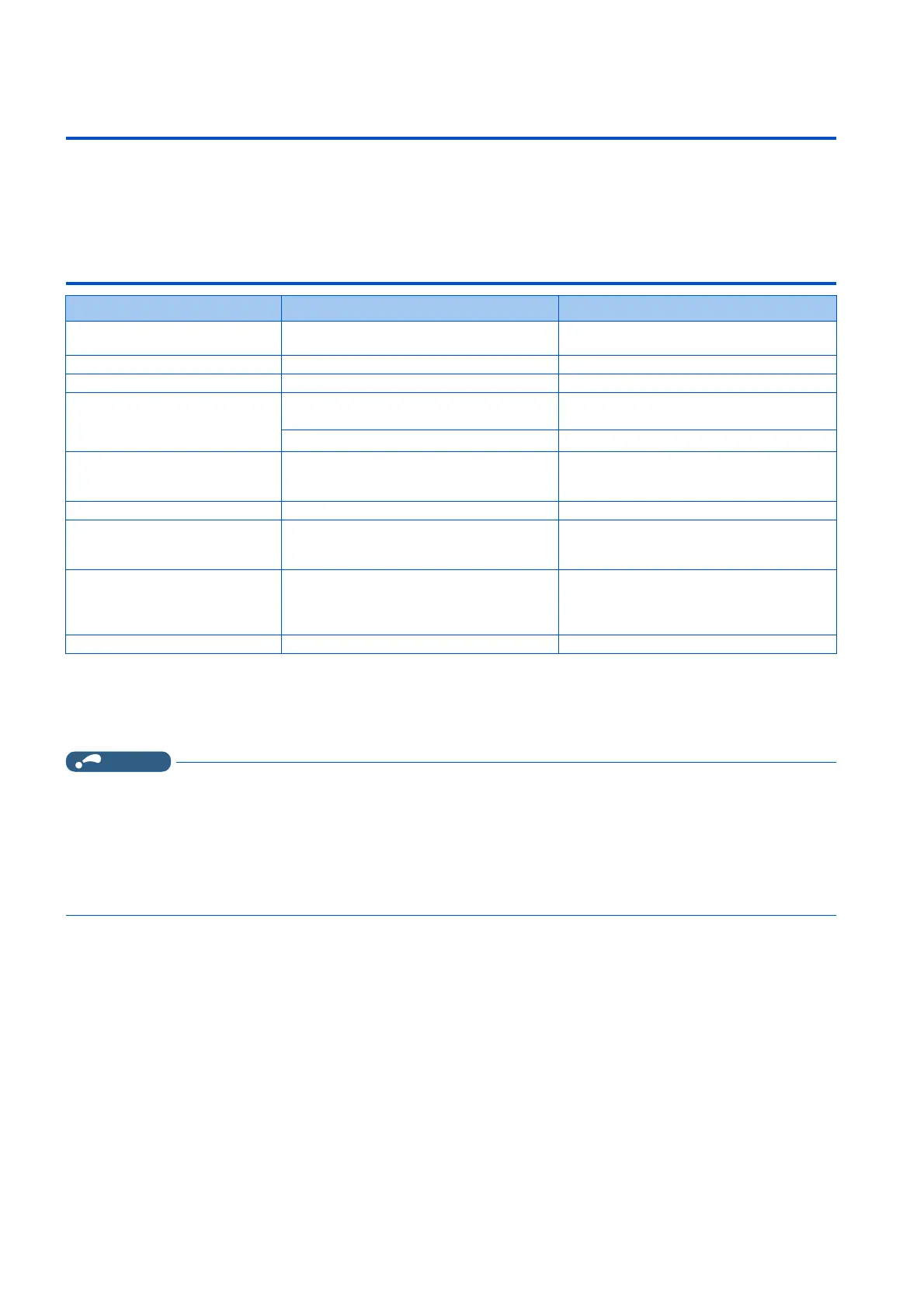

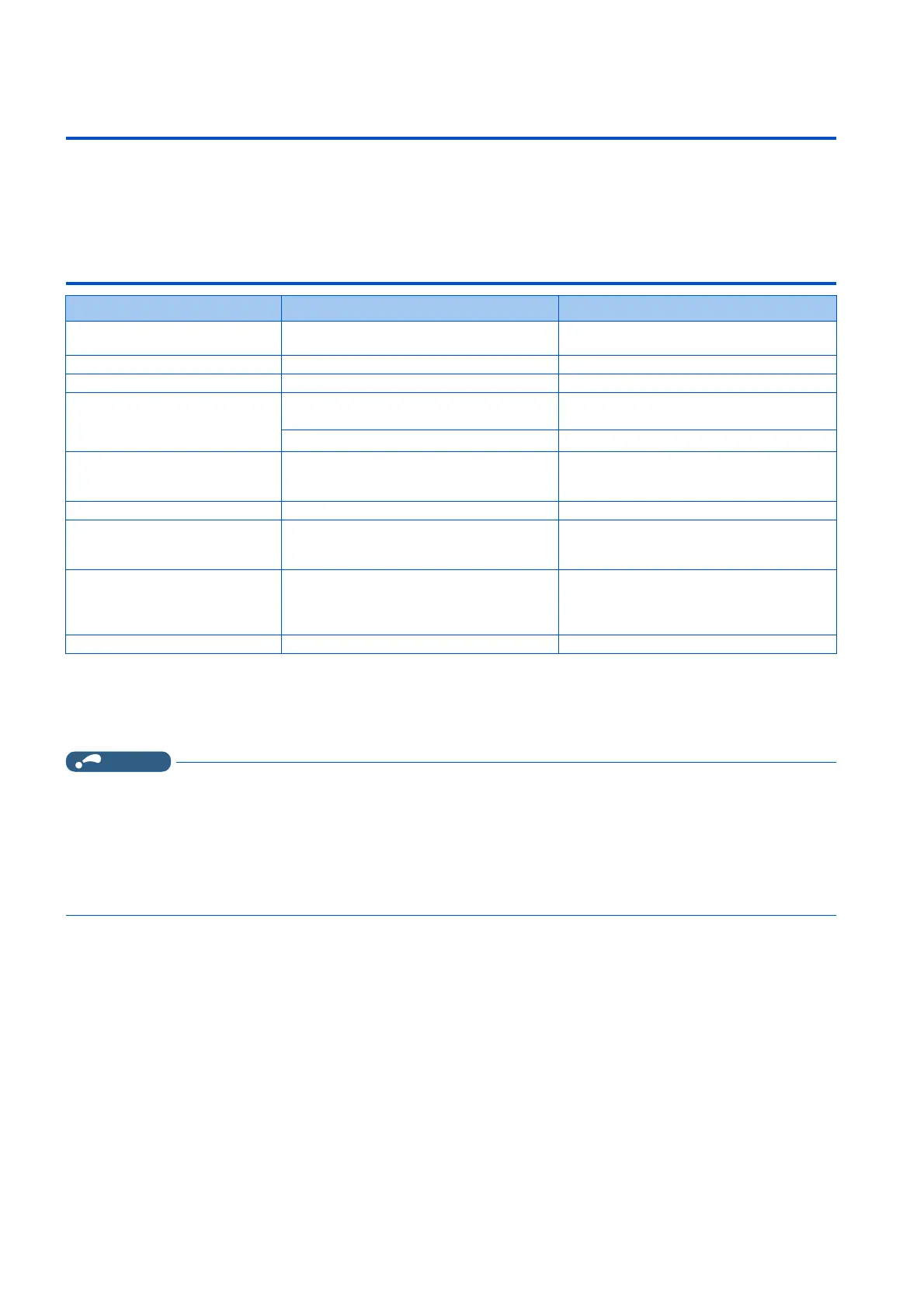

9.1 Specification comparison between PM motor control and induction motor control

9 APPENDIX

APPENDIX provides the reference information for use of this product.

Refer to APPENDIX as required.

9.1 Specification comparison between PM motor

control and induction motor control

*1 For the motor capacity, the rated motor current should be equal to or less than the inverter rated current.

If a motor with substantially low rated current compared with the inverter rated current is used, speed and torque accuracies may deteriorate due

to torque ripples, etc. Set the rated motor current to 40% or higher of the inverter rated current.

*2 For the FR-F860-00680 or lower

*3 For the FR-F860-01080 or higher

• Before wiring, make sure that the motor is stopped. Otherwise you may get an electric shock.

• Never connect a PM motor to the commercial power supply.

• No slippage occurs with a PM motor because of its characteristic. If a PM motor, which took over an induction motor, is

driven at the same frequency as for the general-purpose motor, the rotation speed of the PM motor becomes faster by the

amount of the general-purpose motor's slippage. Adjust the speed command to run the PM motor at the same speed as

the induction motor, as required.

Item PM motor control Induction motor control

Applicable motor PM motor (tuning required)

(The same capacity as the inverter capacity)

Induction motor

*1

Number of connectable motors 1: 1 Several motors can be driven under V/F control.

Maximum starting torque 50% 120% (Advanced magnetic flux vector control)

Carrier frequency Four patterns of 2 kHz, 6 kHz, 10 kHz, and 14

kHz

*2

Selectable between 0.75 kHz to 14.5 kHz

*2

Two patterns of 2 kHz and 6 kHz

*3

0.75 kHz to 6 kHz

*3

Automatic restart after instantaneous

power failure

No startup waiting time.

Using the regeneration avoidance function

together is recommended.

Startup waiting time exists.

Startup delay Startup delay of about 0.1 s for initial tuning. No startup delay.

Driving by the commercial power

supply

Not available

Never connect a PM motor to the commercial

power supply.

Can be driven by the commercial power supply.

Operation during motor coasting While the motor is coasting, an electrical

potential is generated across motor terminals.

Before wiring, make sure that the motor is

stopped.

While the motor is coasting, no potential is

generated across motor terminals.

Maximum motor wiring length 100 m or shorter Overall length: 500 m or shorter

Loading...

Loading...