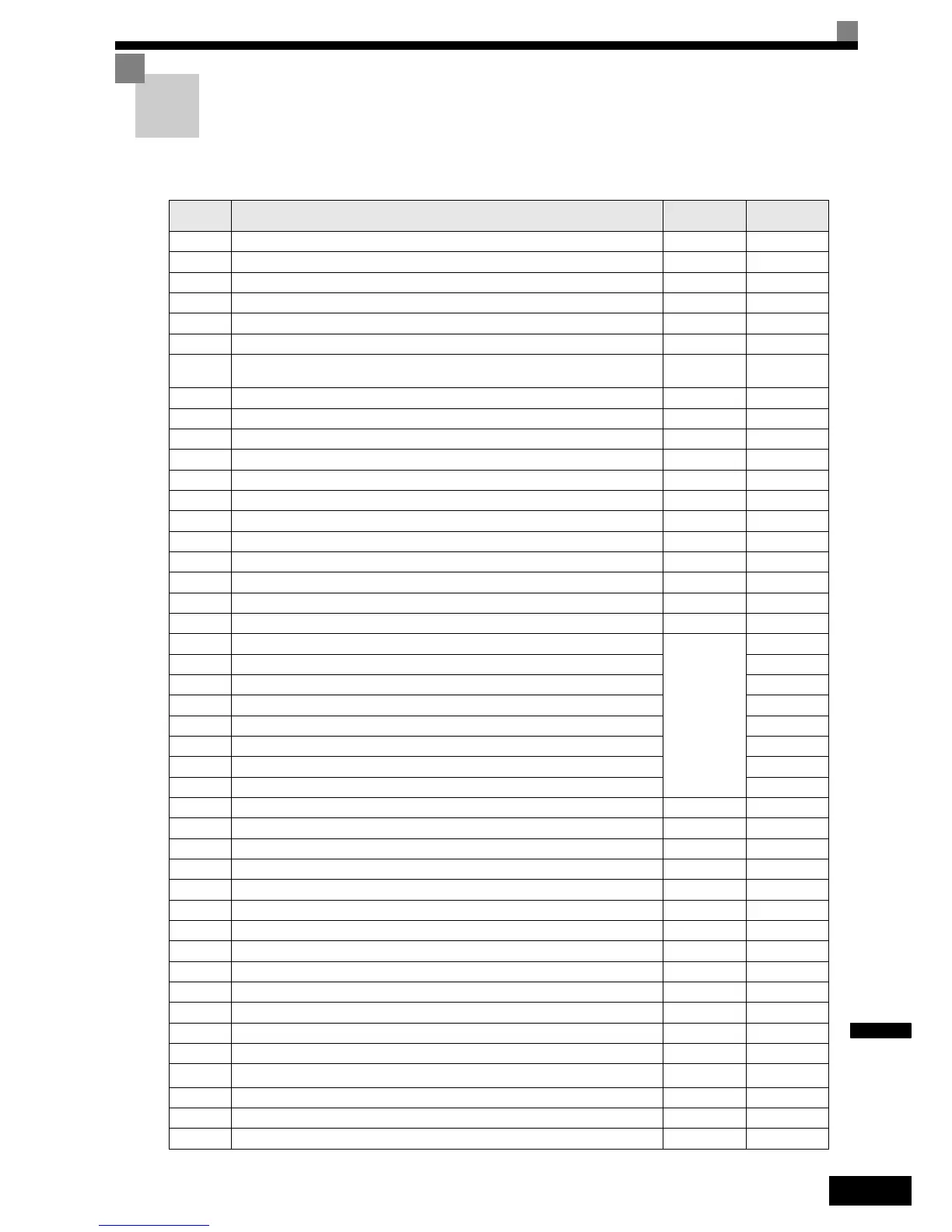

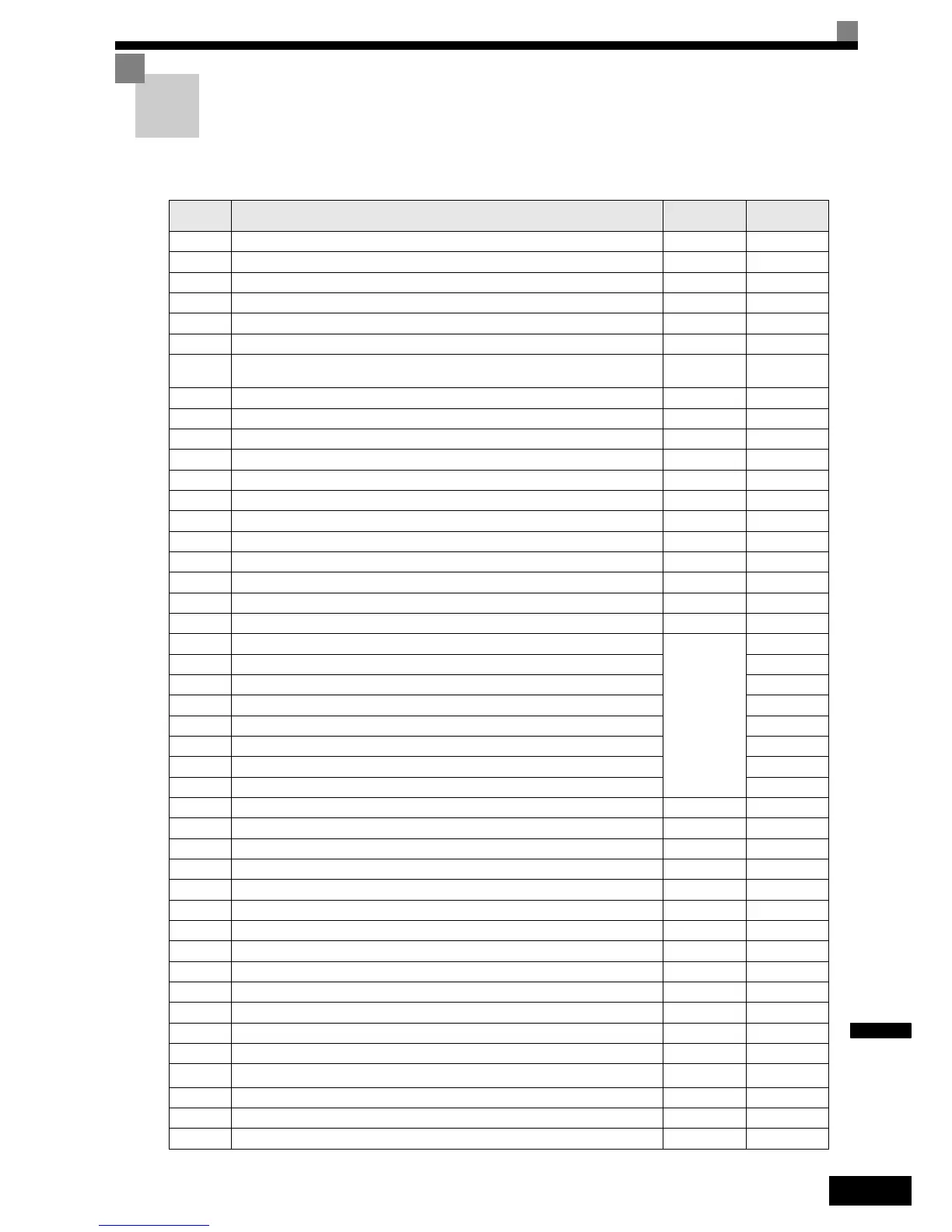

10-5

10

User Constants

The factory settings of each parameter are given in the following table. They are for a 200 V Class Inverter

with 3.7 kW.

No. Name

Factory

Setting

Setting

A1-00 Language selection for Digital Operator display 0

A1-01 Parameter access level 2

A1-02 Control method selection 0

A1-03 Initialize 0

A1-04 Password 0

A1-05 Password setting 0

A2-01 to

A2-32

User specified parameters –

b1-01 Reference source selection 0

b1-02 RUN command source selection 1

b1-06 Control input scan 1

b1-08 Run command selection in programming modes 1

b2-08 Magnetic flux compensation volume 0%

b4-01 Timer function ON-delay time 0.0 sec.

b4-02 Timer function OFF-delay time 0.0 sec.

b6-01 Dwell frequency at start 0.0 Hz

b6-02 Dwell time at start 0.0 sec.

b6-03 Dwell frequency at stop 0.0 Hz

b6-04 Dwell time at stop 0.0 sec.

C1-01 Acceleration time 1 10.0 sec.

C1-02 Deceleration time 1

1.5 s

C1-03 Acceleration time 2

C1-04 Deceleration time 2

C1-05 Acceleration time 3

C1-06 Deceleration time 3

C1-07 Acceleration time 4

C1-08 Deceleration time 4

C1-09 Emergency stop time

C1-10 Accel/decel time setting unit 1

C1-11 Accel/decel time switching frequency 0.0 Hz

C2-01 S-curve characteristic time at acceleration start 0.5 sec.

C2-02 S-curve characteristic time at acceleration end 0.5 sec.

C2-03 S-curve characteristic time at deceleration start 0.5 sec.

C2-04 S-curve characteristic time at deceleration end 0.5 sec.

C2-05 S-curve Characteristic time below leveling speed 0.50 sec.

C3-01 Slip compensation gain 1.0

C3-02 Slip compensation delay time 2000 msec

C3-03 Slip compensation limit 200%

C3-04 Slip compensation selection during regeneration 1

C3-05 Output voltage limit operation selection 1

C4-01 Torque compensation gain 1.00

C4-02 Torque compensation delay time constant

200 msec

*1

C4-03 Starting torque compensation (FWD) 0.0%

C4-04 Starting torque compensation (REV) 0.0%

C4-05 Starting torque compensation time constant 10 msec

Loading...

Loading...