Process Control

SM 6-11 G133

Detailed

Descriptions

ID sensor until its output when reading the bare transfer belt (known as VSG) is as follows.

VSG = 4.0 ± 0.5 Volts

This calibration compensates for the transfer belt’s condition and the ID sensor condition.

For example, dirt on the surface of the belt or ID sensor.

VSG adjustment is always done during initial process control. But, at other times, it is only

done if the VSG adjustment counter (SP3-510-007) is more than the value set with

SP3-511-007 (default: 500) during a job or at job end.

SC400 is displayed if VSG is out of adjustment range sequentially 3 times.

SP3-321: Forced VSG Adjustment for each sensor

SP 3-325: Shows the results of the VSG adjustment (automatic or forced VSG adjustment)

- 7 digits (Front, Bk, C, Center, M, Y, Rear)

Step 2: ID Sensor Solid Pattern Generation

First, the machine agitates the developer for between 15 and 30 seconds until the

fluctuation in TD sensor output becomes less than 0.3V.

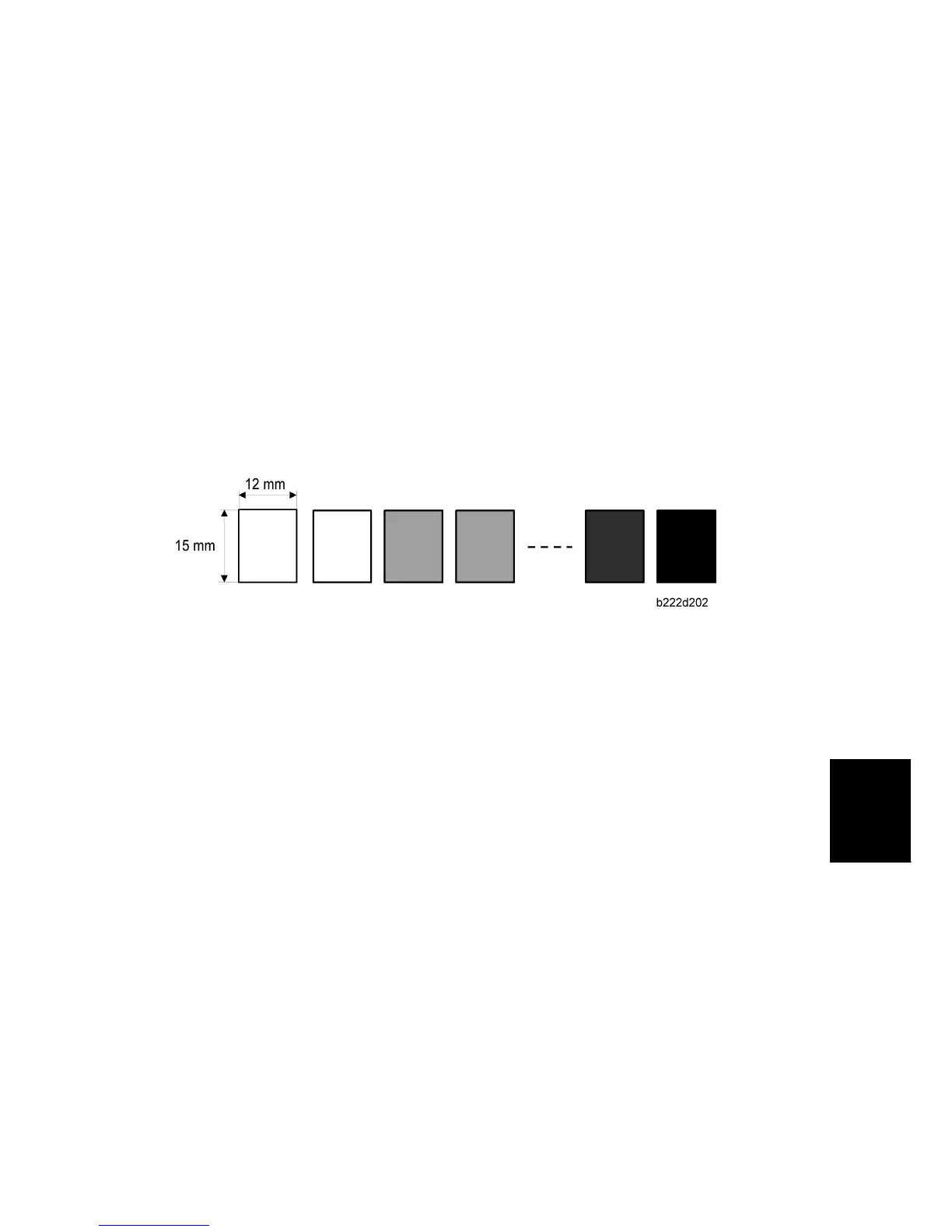

Second, the machine makes the grade patterns (see the diagram). This 10-grade pattern is

made in black, yellow, cyan, and magenta (40 squares in total).

The machine first makes the first five grades for each color (the first 20 squares), and

then the second five grades for each color (the remaining 20 squares).

The patterns are made by changing the development bias and charge roller voltage. The

difference between development bias and charge roller voltage is always the same. But,

the development potential changes for each pattern.

The development potential is the difference between the development bias and the

charge remaining on the drum where the laser writes a black area. The development

bias changes for each grade, and the charge on black areas of the image is always the

same, so the development potential also changes.

Step 3: Sensor Pattern Detection

The ID sensor measures the light reflected from each grade of the pattern, to detect the

densities of each grade. This data goes to memory.

Step 4: Toner Amount Calculation

The machine calculates the amount of toner on the transfer belt that is required to make

Loading...

Loading...