SC Tables: SC3xx

G179 4-6 SM

4.4 SC TABLES: SC3XX

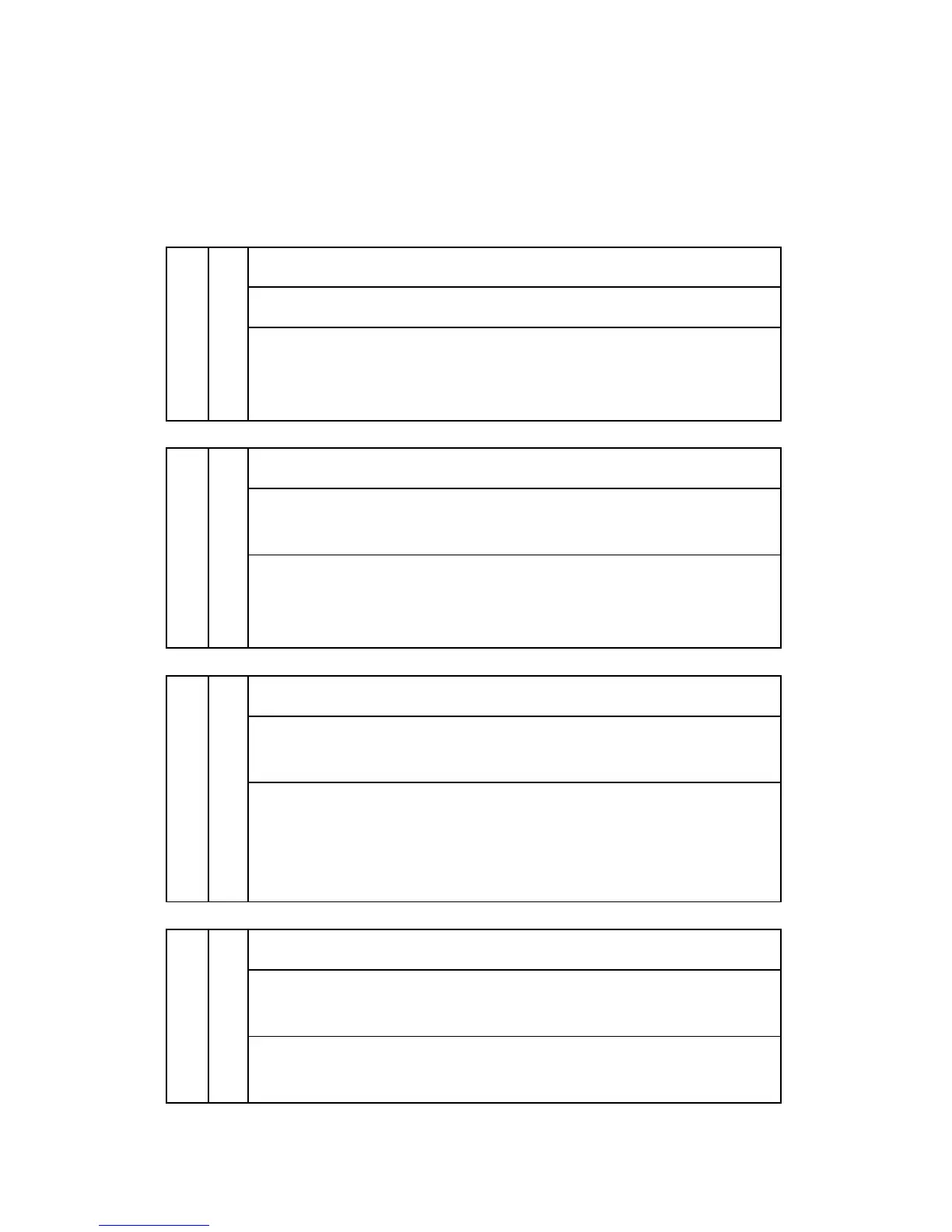

Charge roller bias leak

The charge roller bias leak signal is detected.

302 D

Charge roller damaged

High voltage supply board defective

PCDU harness defective or disconnected

Charge roller bias correction leak

The charge roller bias correction is performed twice even if the maximum

charge roller bias (-2000V) is applied to the roller.

304 D

ID sensor defective

Worn charge roller

Charge roller damaged

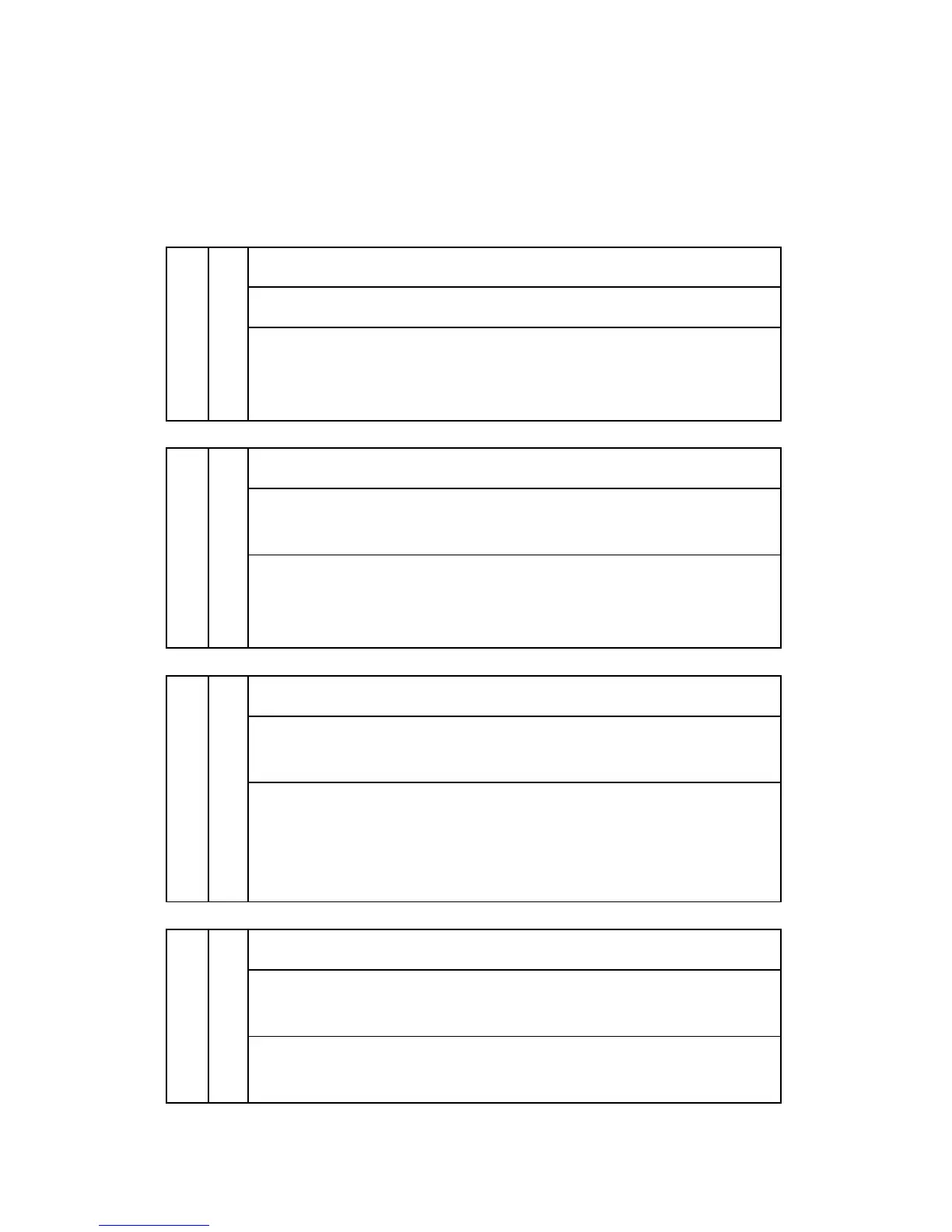

Development roller bias leak

A development roller bias leak is detected for 60 ms after the high voltage

has been supplied to the development unit.

320 D

Development bias leak

Broken harness

Defective high voltage power supply, voltage supply

Defective high voltage supply unit

Development paddle motor error

The machine detects a lock signal error from the development puddle motor

for 2 seconds after the drum motor has turned on.

324 D

Overload on the development puddle motor

Defective development puddle motor

Loading...

Loading...