Development

SM 6-27 G179

Detailed

Descriptions

Toner Supply Mechanism

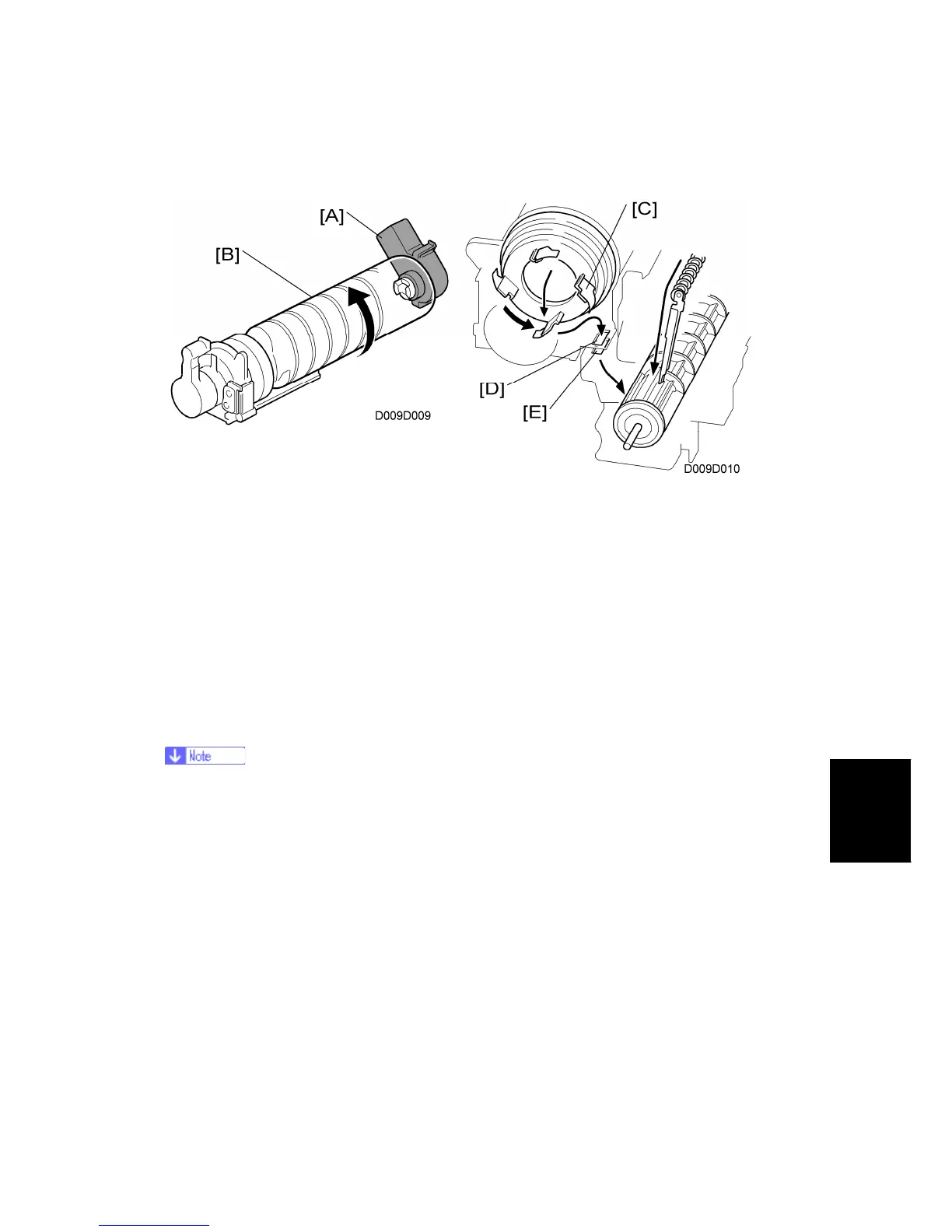

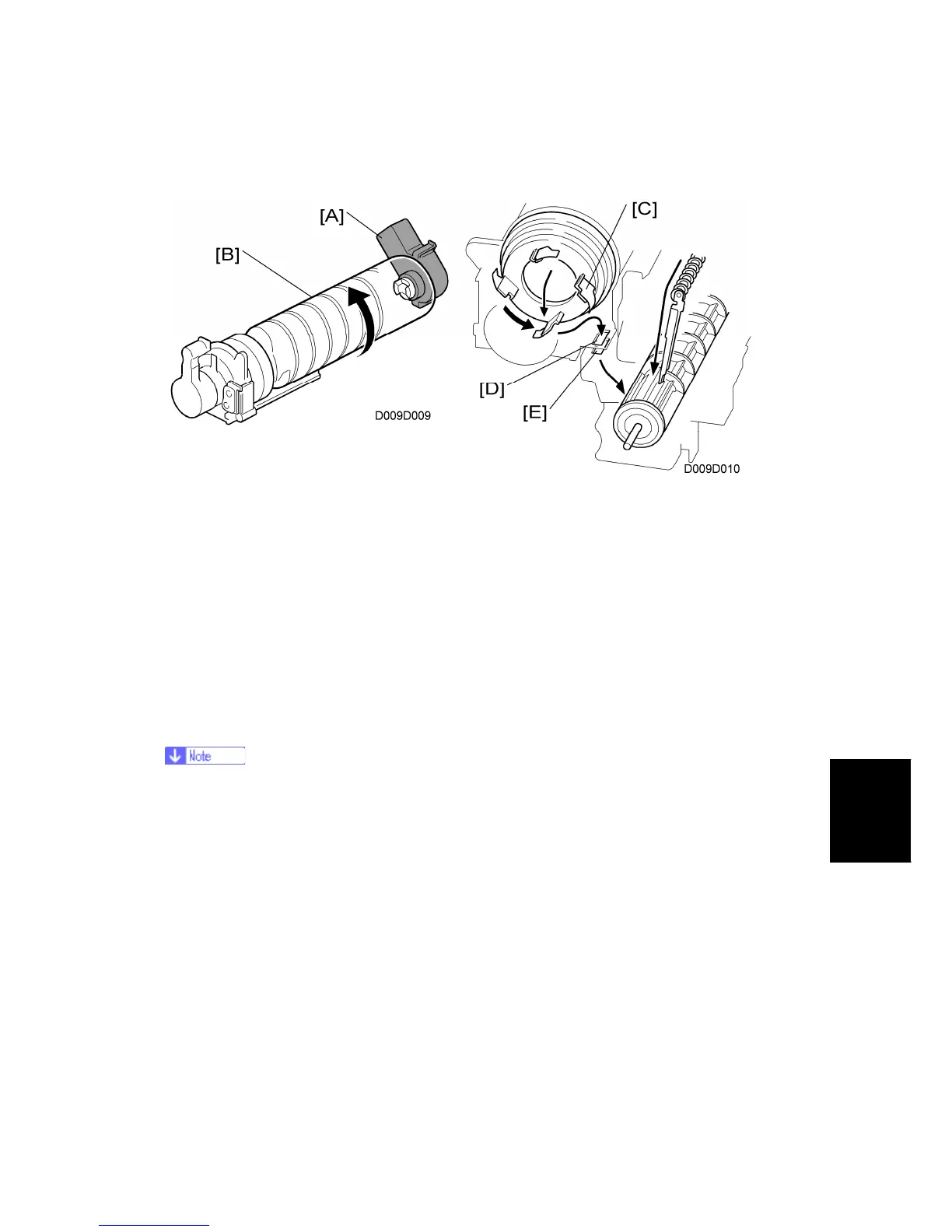

The toner supply motor [A] rotates the toner bottle [B] and the mylar blades [C]

Toner falls into the toner bottle holder, and the toner supply mylar blades [C] transfer the

toner to slit [D]. The toner falls into the development unit through the port [E].The left side of

the entrance seal is higher than the right. This improves the efficiency of seal on the left

side, especially when the drum is removed.

Toner Density Control

There are two modes for controlling and maintaining constant toner supply: sensor control

(both direct and indirect) and image pixel count control. The mode can be changed with

SP2-208-1 (Toner Supply Mode).

The factory setting is sensor control mode; image pixel count mode should only be

used temporarily until a defective TD or ID sensor can be replaced.

Sensor Control Mode

In the sensor control mode, the amount of toner required to print the page is calculated by

the CPU; it adds up the image data value of each pixel and converts the sum to a value

between 0 and 255. (255 would mean a completely black page.)

The machine must vary toner supply for each print in order to maintain the correct amount

of toner in the developer and to account for changes in drum reflectivity due to changes in

temperature and humidity. The CPU uses data from the TD sensor and ID sensor to

determine whether or not the toner supply motor should be switched on and to calculate

how long it should remain on in order to supply more toner to the mixture in the

development unit.

Loading...

Loading...