Loading...

Loading...

Do you have a question about the Ricoh G179 and is the answer not in the manual?

| Brand | Ricoh |

|---|---|

| Model | G179 |

| Category | All in One Printer |

| Language | English |

Specifies environmental, power, and space requirements for machine installation.

Provides critical safety and handling cautions before replacement or adjustment.

Covers safety precautions and procedures for replacing the laser unit.

Explains the replacement and re-installation procedures for the PCDU.

Details procedures for replacing the development filter, roller, and developer.

Covers replacement procedures for the transfer belt unit and related components.

Provides steps for replacing paper feed unit components like rollers and motors.

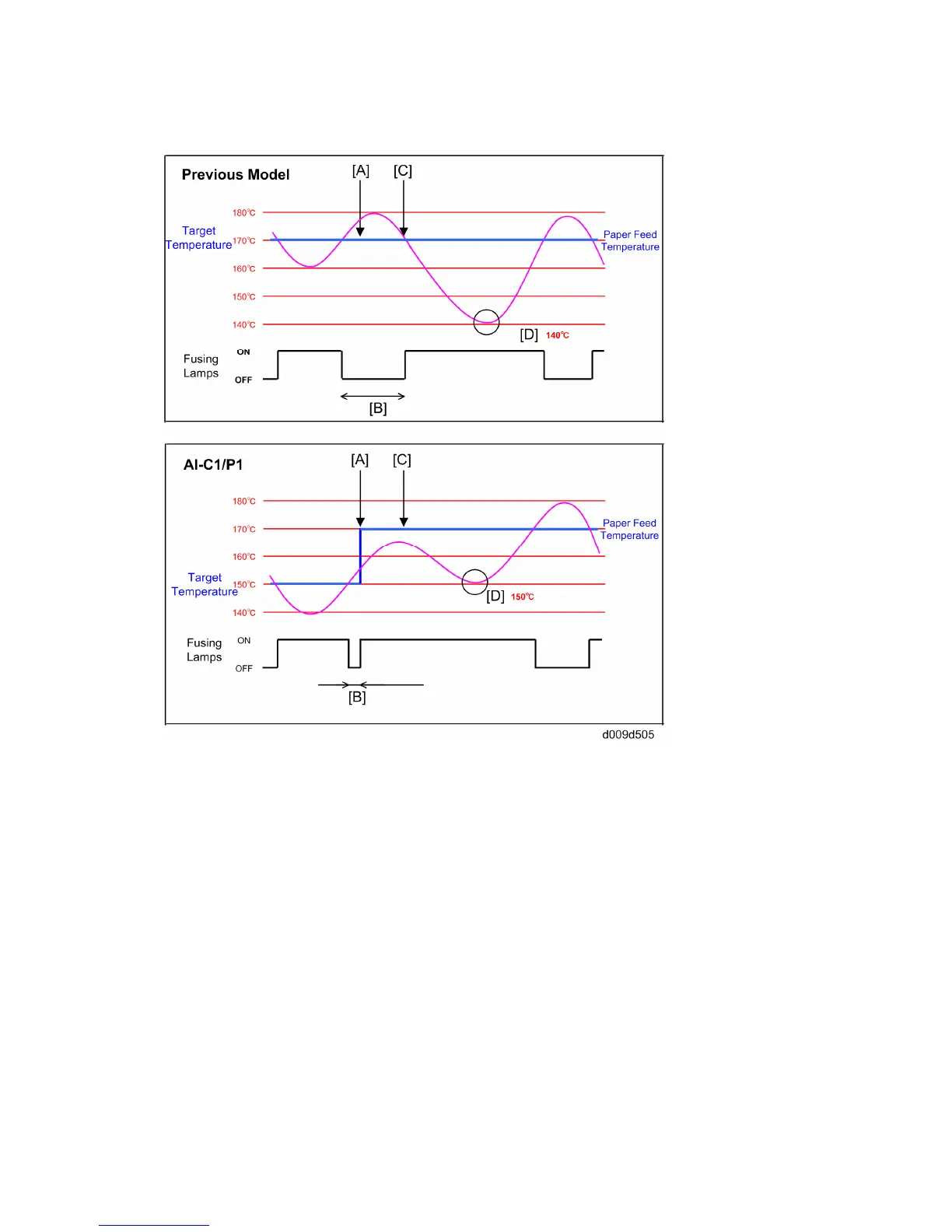

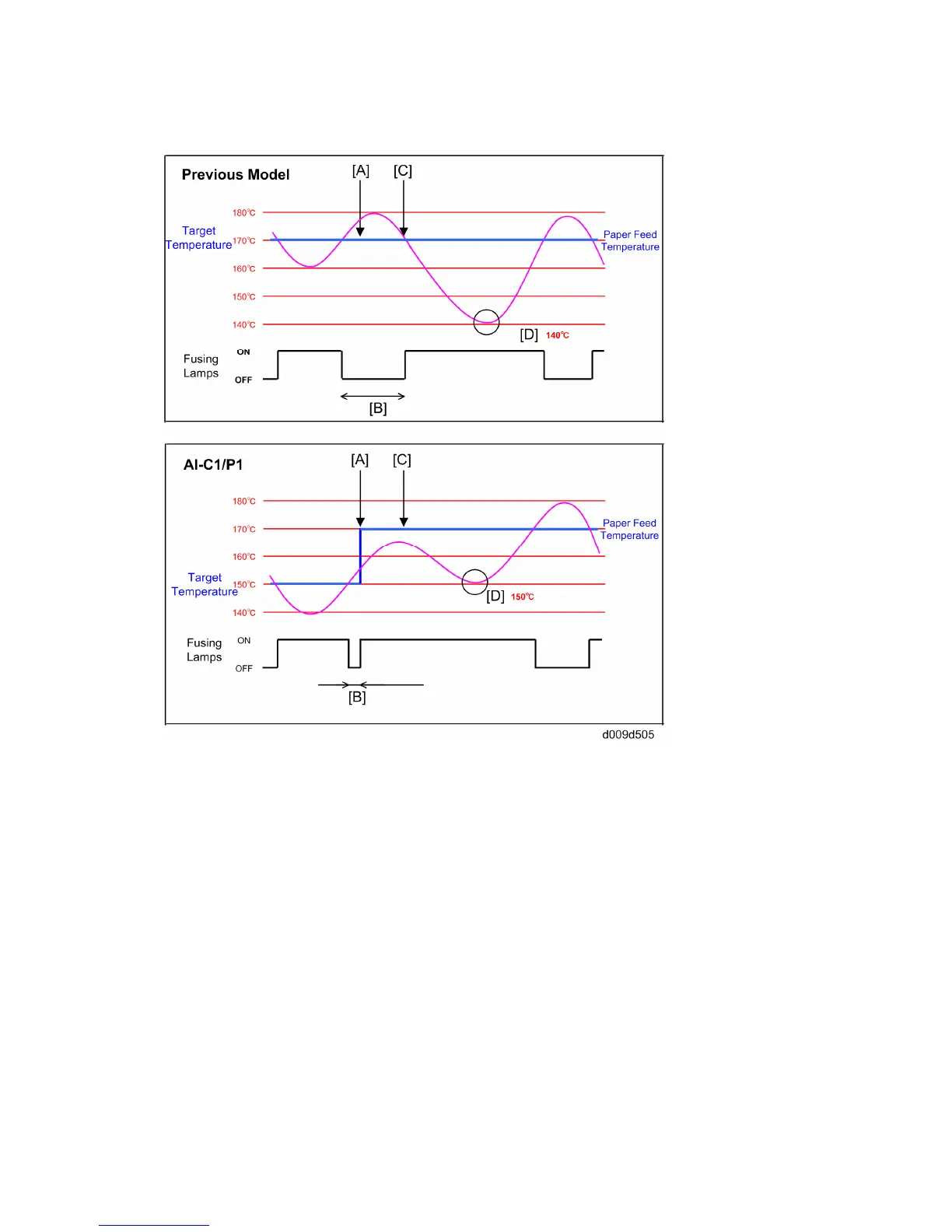

Details procedures for replacing fusing unit components like rollers and heaters.

Explains replacement procedures for paper exit unit components and sensors.

Covers replacement procedures for duplex unit components like motors and sensors.

Details replacement procedures for by-pass paper size and end sensors.

Covers replacement procedures for various drive motors and clutches.

Explains replacement procedures for electrical components like controller and power boards.

Explains the different levels of service call conditions and their reset procedures.

Lists common electrical component defects, their CN, conditions, and symptoms.

Details blown fuse conditions, ratings, and symptoms at power on.

Provides detailed steps for updating the machine's firmware via SD card.

Describes the self-diagnostic mode at power-on and test flows.

Lists jam detection modes, staple status, and content for troubleshooting.

Covers replacement of control board, drive motor, tray exit, and relay sensors.