GENERAL INFORMATION

- 20 -

around an object. Close the micrometer around the highest point so it can be removed with a slight

drag.

Adjustment

Before using a micrometer, check its adjustment as follows:

1. Clean the anvil and spindle faces.

2A. To check a 0-1 in. or 0-25 mm micrometer:

a. Turn the thimble until the spindle contacts the anvil. If the micrometer has a ratchet stop, use

it to ensure that the proper amount of pressure is applied.

b. If the adjustment is correct, the 0 mark on the thimble will align exactly with the 0 mark on

the sleeve line. If the marks do not align, the micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to adjust the micrometer.

2B. To check a micrometer larger than 1 in. or 25 mm use the standard gauge supplied by the

manufacturer. A standard gauge is a steel block, disc or rod that is machined to an exact size.

a. Place the standard gauge between the spindle and anvil, and measure its outside diameter

or length. If the micrometer has a ratchet stop, use it to ensure that the proper amount of

pressure is applied.

b. If the adjustment is correct, the 0 mark on the thimble will align exactly with the 0 mark on the

sleeve line. If the marks do not align, the micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to adjust the micrometer.

Care

Micrometers are precision instruments. They must be used and maintained with great care. Note

the following:

1. Store micrometers in protective cases or separate padded drawers in a tool box.

2. When in storage, make sure the spindle and anvil faces do not contact each other or another

object. If they do, temperature changes and corrosion may damage the contact faces.

3. Do not clean a micrometer with compressed air. Dirt forced into the tool will cause wear.

4. Lubricate micrometers with WD-40 to prevent corrosion.

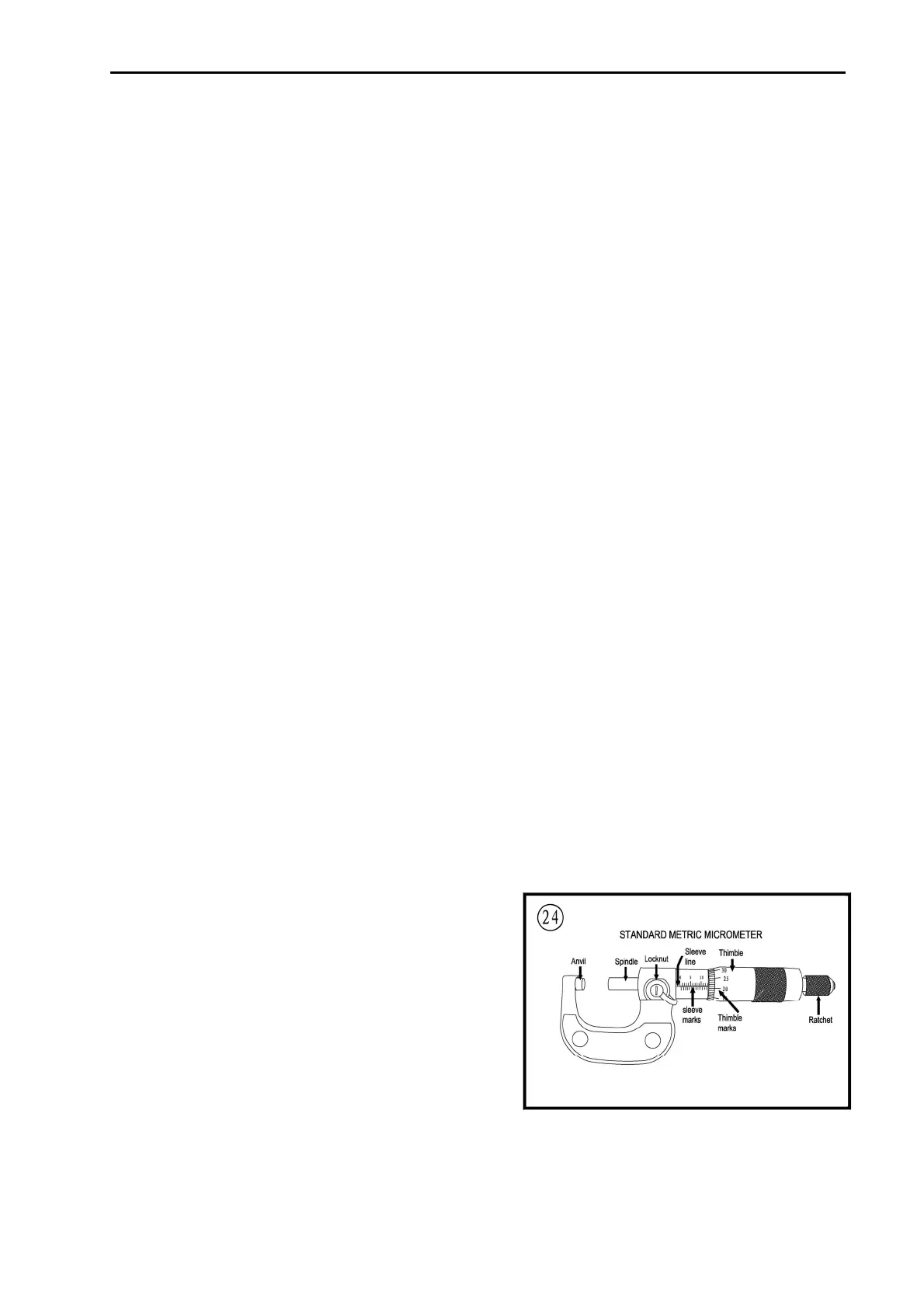

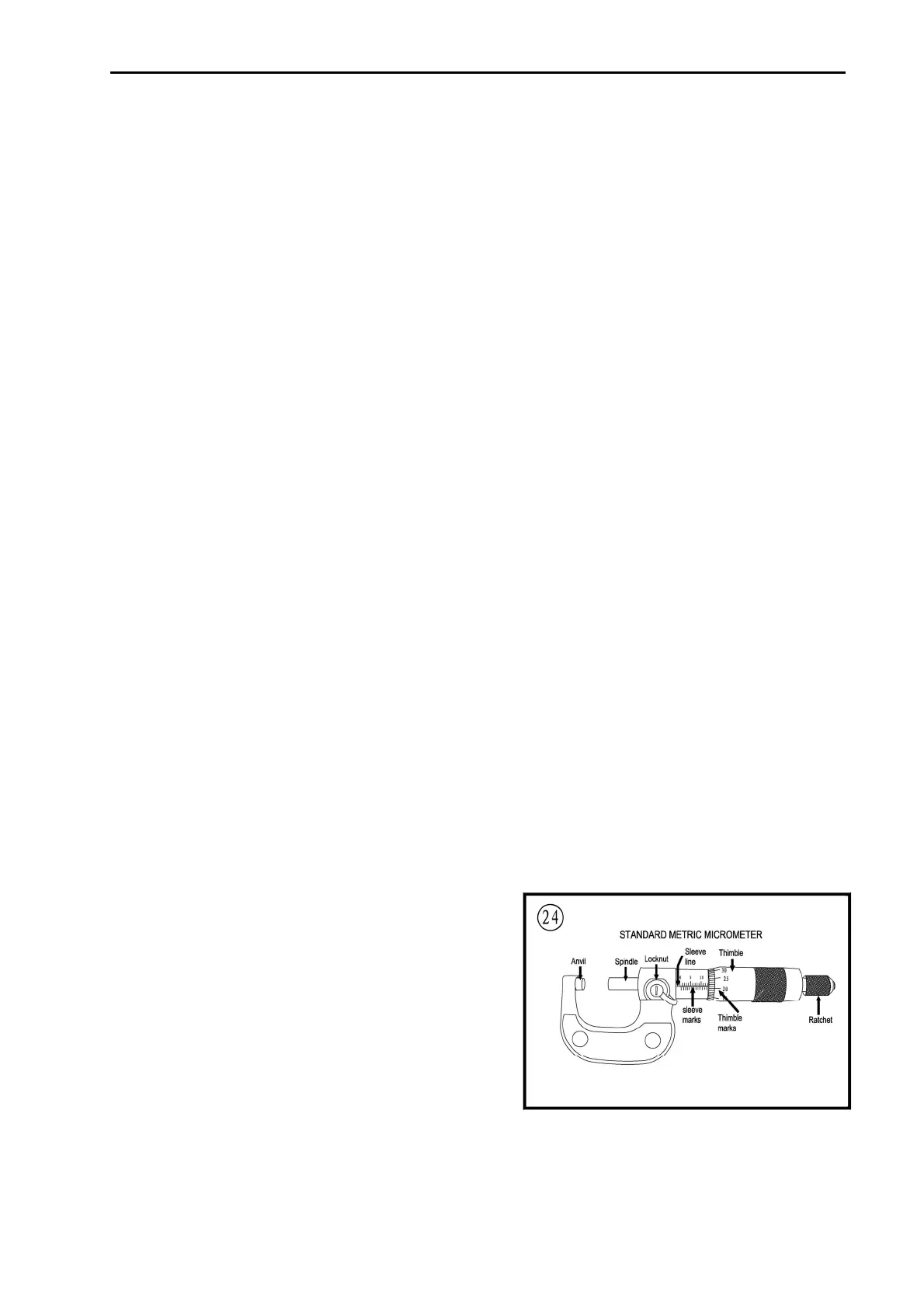

Metric micrometer

The standard metric micrometer (Figure 24) is

accurate to one one-hundredth of a millimeter (0.01

mm). The sleeve line is graduated in millimeter and

half millimeter increments. The marks on the upper

half of the sleeve line equal 1.00 mm. Each fifth mark

above the sleeve line is identified with a number. The

number sequence depends on the size of the

micrometer. A 0-25 mm micrometer, for example, will have sleeve marks numbered 0 through 25 in 5

Loading...

Loading...