GENERAL INFORMATION

- 22 -

2. Count the number of lines between the numbered sleeve mark and the edge of the thimble. Each

sleeve mark equals 0.025 in.

3. Read the thimble mark that aligns with the sleeve line. Each thimble mark equals 0.01 in.

NOTE

If a thimble mark does not align exactly with the

sleeve line, estimate the amount between the

lines. For accurate readings in ten-thousandths

of an inch (0.0001 in), use a vernier inch

micrometer.

4. Add the readings from Steps 1-3.

Telescoping and Small Bore Gauges

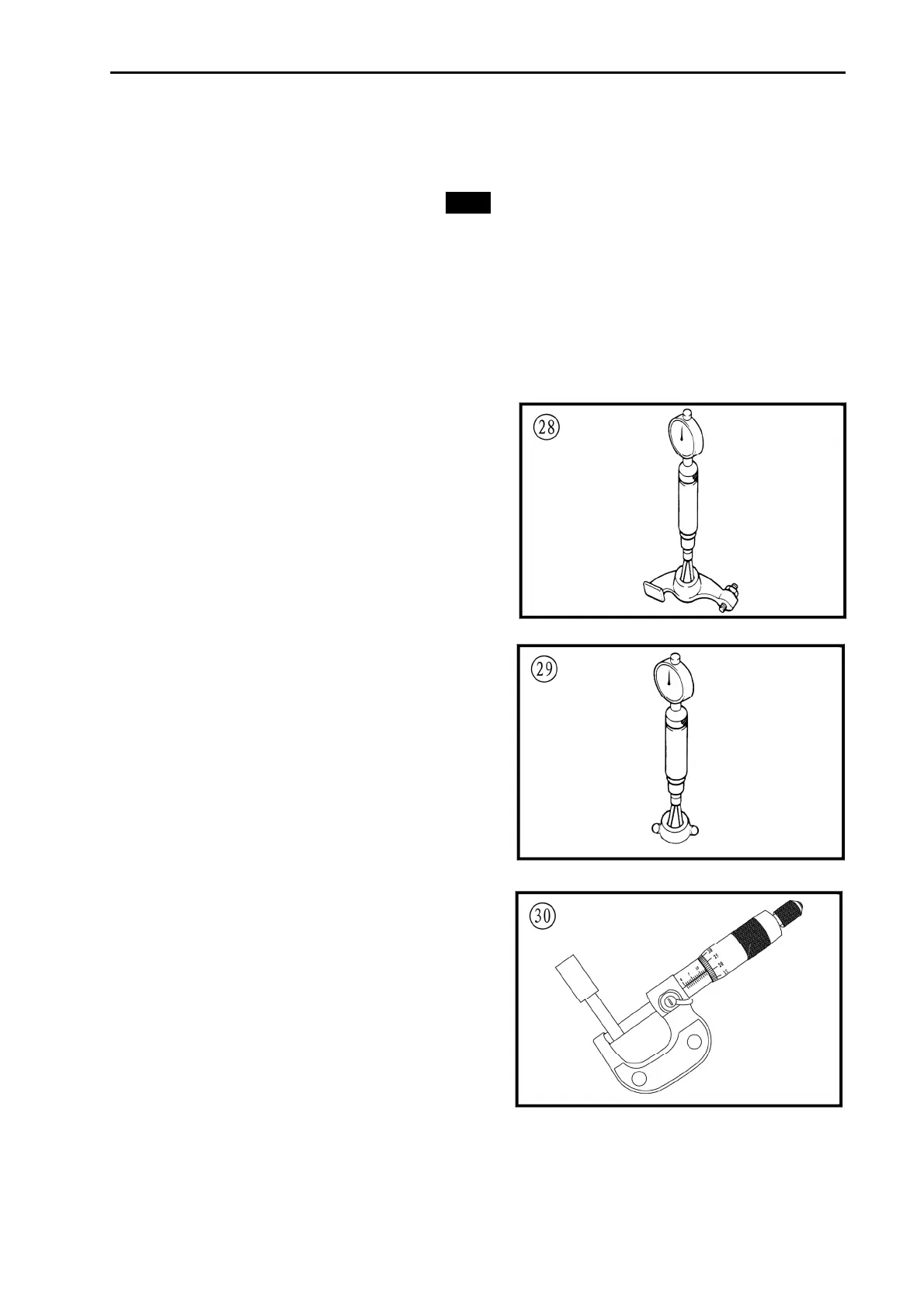

Use telescoping gauges (Figure 28) and small

bore gauges (Figure 29) to measure bores. Neither

gauge has a scale for direct readings. Use an outside

micrometer to determine the reading.

To use a telescoping gauge, select the correct

size gauge for the bore. Compress the movable post

and. Care fully insert the gauge into the bore. Carefully

move the gauge in the bore to make sure it is centered.

Tighten the knurled end of the gauge to hold the

movable post in position. Remove the gauge and

measure the length of the posts. Telescoping gauges

are typically used to measure cylinder bores.

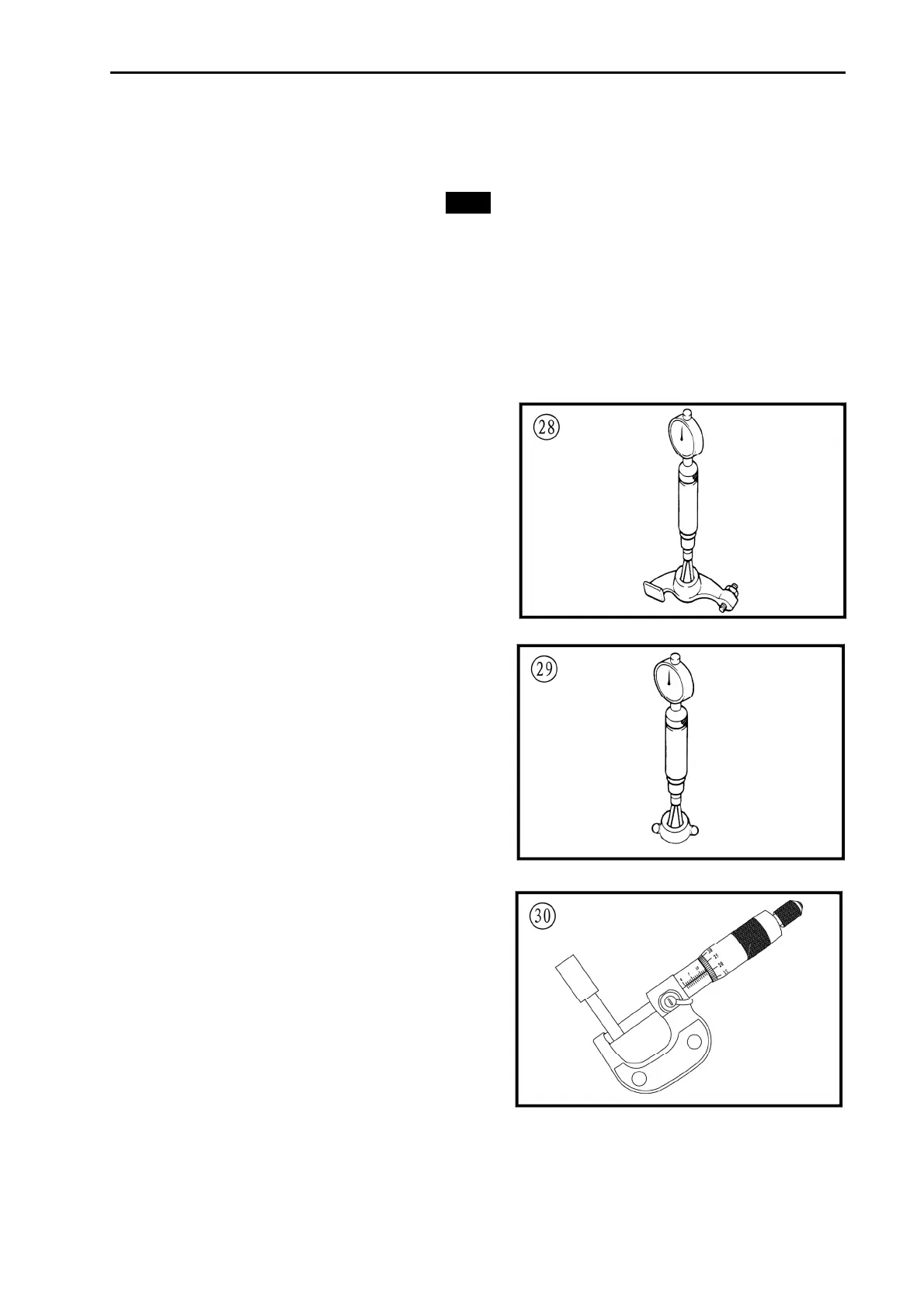

To use a small bore gauge, select the correct size

gauge for the bore. Carefully insert the gauge into the

bore. Tighten the knurled end of the gauge to carefully

expand the gauge fingers to the limit within the bore.

Do not over tighten the gauge because there is no

built-in release. Excessive tightening can damage the

bore surface and damage the tool. Remove the

gauge and measure the outside dimension (Figure

30). Small bore gauges are typically used to

measure valve guides.

Dial Indicator:

A dial indicator (Figure 31) is a gauge with a dial

face and needle used to measure variations in

dimensions and movements. Measuring brake rotor

runout is a typical use for a dial indicator.

Loading...

Loading...