MAINTENANCE

7-94

J. Tire

Check and Replace Tire (Tire Pressure)

Check appearance --- 10 hours (daily)

f

NOTE: Check tire pressure when appearance is

questionable or each week (50 hours)

Replace --- as necessary

d

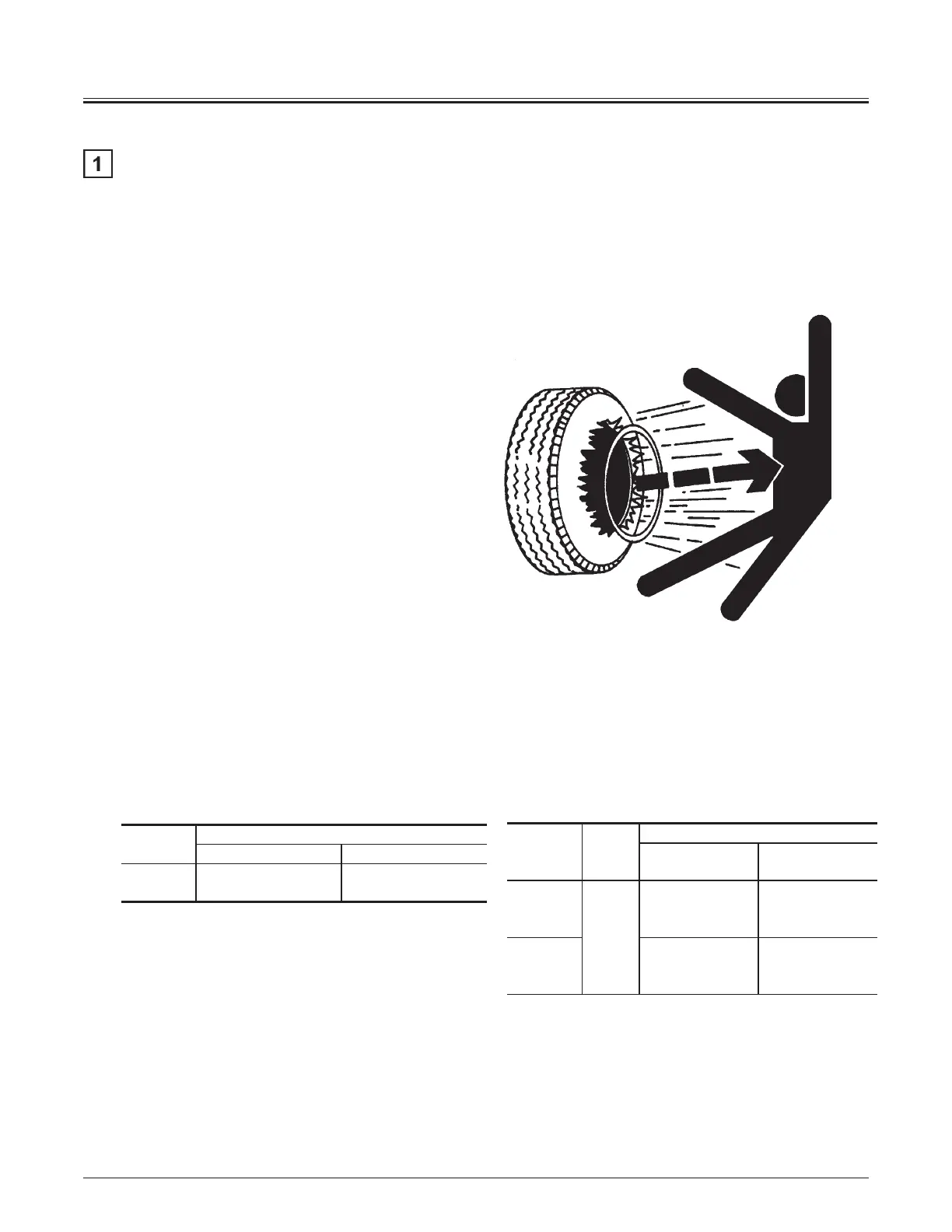

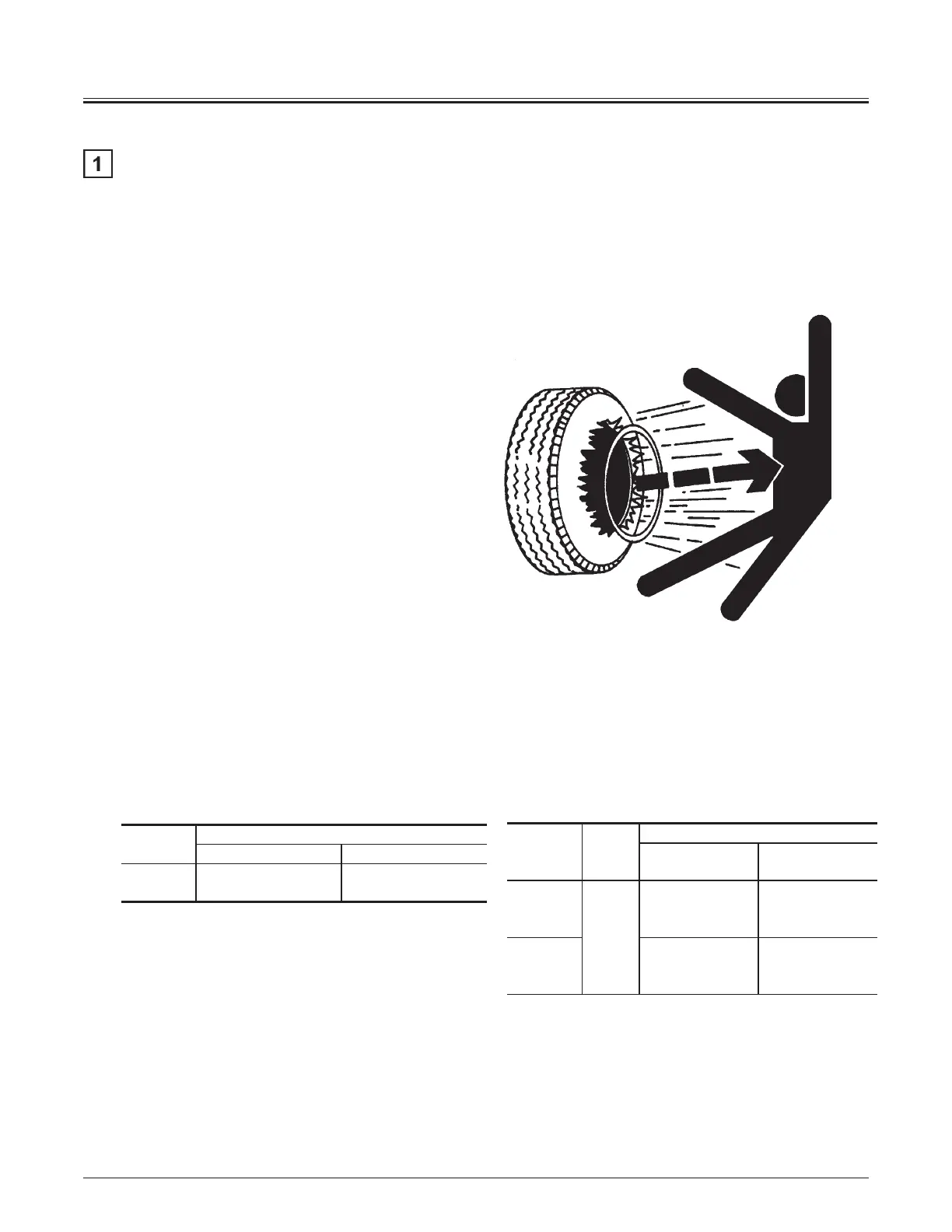

WARNING:

Secure the front and rear chassis with the

articulation stopper (lock bar and pins).

When inflating tires, stand behind the tread and

use the self-attaching chuck with a line extension.

Avoid welding near tires, which could potentially

cause the tires to explode.

A tire may explode if it is smoking due to intense

heat such as if the machine catches fire.

Never weld on rims. Replace defective rims.

IMPORTANT:

Always maintain the correct tire pressure.

Even if only one tread pattern has worn out,

replace the tire with new one. Tires must be

evenly sized. Before operating the machine,

check the tires for damage.

When replacing one tire, use a new tire having the

same tread pattern and specification as the other

tires.

Check Air Pressure

1. Measure air pressure when the tires are cool before

operating the machine.

Radial tire

(standard)

Standard Air pressure

Front Rear

35/65R33

471~490 kPa (4.8~5.0

kgf/cm

2

) (68~71 PSI)

373~392 kPa (3.8~4.0

kgf/cm

2

) (54~57 PSI)

2. Check tires for damage and/or excessive wear.

Bias

ply tire

(option)

Pattern

Standard Air pressure

Front Rear

29.5-29-

28PR

L4, L5

520~539 kPa

(5.3~5.5 kgf/cm

2

)

(75~78 PSI)

422~441 kPa

(4.3~4.5 kgf/cm

2

)

(61~64 PSI)

35/65-33-

24PR

422~441 kPa

(4.3~4.5 kgf/cm

2

)

(61~64 PSI)

324~343 kPa

(3.3~3.5 kgf/cm

2

)

(47~50 PSI)

SA-249

Loading...

Loading...