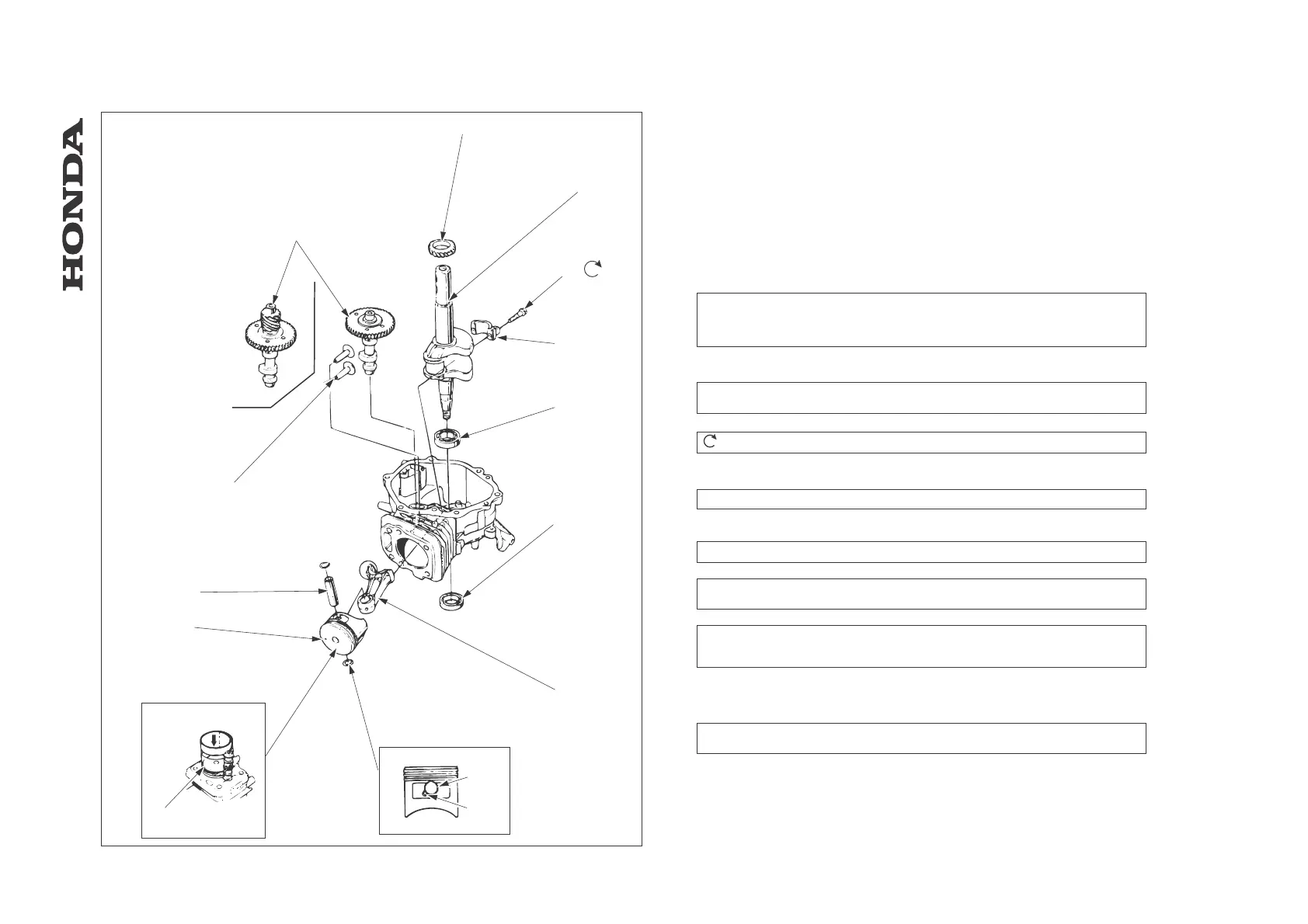

12. CRANKSHAFT / PISTON / CYLINDER

12.1 Disassembly / Reassembly

1. Remove the engine (ch. 5) then remove the following:

- Air cleaner and muffler (ch. 6).

- Fuel tank (ch. 7).

- Control arm and carburetor (ch. 8).

- Flywheel and starter motor (ch. 9).

- Cylinder head (ch. 10).

- Oil pan (ch. 11).

[1] CAMSHAFT

VALVE TIMING ADJUSTMENT: ch. 12.1

INSPECTION: ch. 12.2

[A] HRD535/K1/K2 Q type - HRA536

[B] HRD535/K1 except Q type - HRD536/K1/K2

[2] TIMING GEAR

[3] CRANKSHAFT

REASSEMBLY: Push in firmly until contact is made with the bearing surface.

Be careful not to damage the oil seal lip.

[4] CONNECTING ROD SCREW

TIGHTNING TORQUE: 12 N.m

[5] LOWER CAP

[6]

BALL BEARING (HRD535/K1/K2: 62/22, HRA536 - HRD536/K1/K2: 6205)

REPLACEMENT: ch. 12.1

[7]

OIL SEAL (HRD535/K1/K2: 22x35x6mm,

HRA536 - HRD536/K1/K2: 25x38x7mm

REASSEMBLY: ch. 12.1

[8] CONNECTING ROD

REASSEMBLY: Make sure that the longer end mark “A” facing side of the piston head

with the “+” mark.

[9] PISTON PIN SNAP RING (2)

REASSEMBLY: Install by setting one end of snap ring in the piston cut-out, holding the

other edge with long-nosed pliers, and rotating the snap ring in. Do not align the end gap

of the snap ring with the cut-out in the piston pin bore.

[9]-1 SNAP RING

[9]-2 CUT-OUT

[10] PISTON

REASSEMBLY: Install the piston using a piston slider (commercially available) and

facing the “+” mark toward the push rods.

[10]-1 PISTON SLIDER ...............................................commercially available

[11] “+” MARK

[12] PISTON PIN

[13] VALVE LIFTER (2)

-75-

HRA536 - HRD535 - HRD536

[1]

[

]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[9]-1

[9]-2

[10]

[10]-1

[11]

[12]

[13]

[A]

[B]

12

- OIL PAN / DRIVE SHAFT / GOVERNOR

Loading...

Loading...