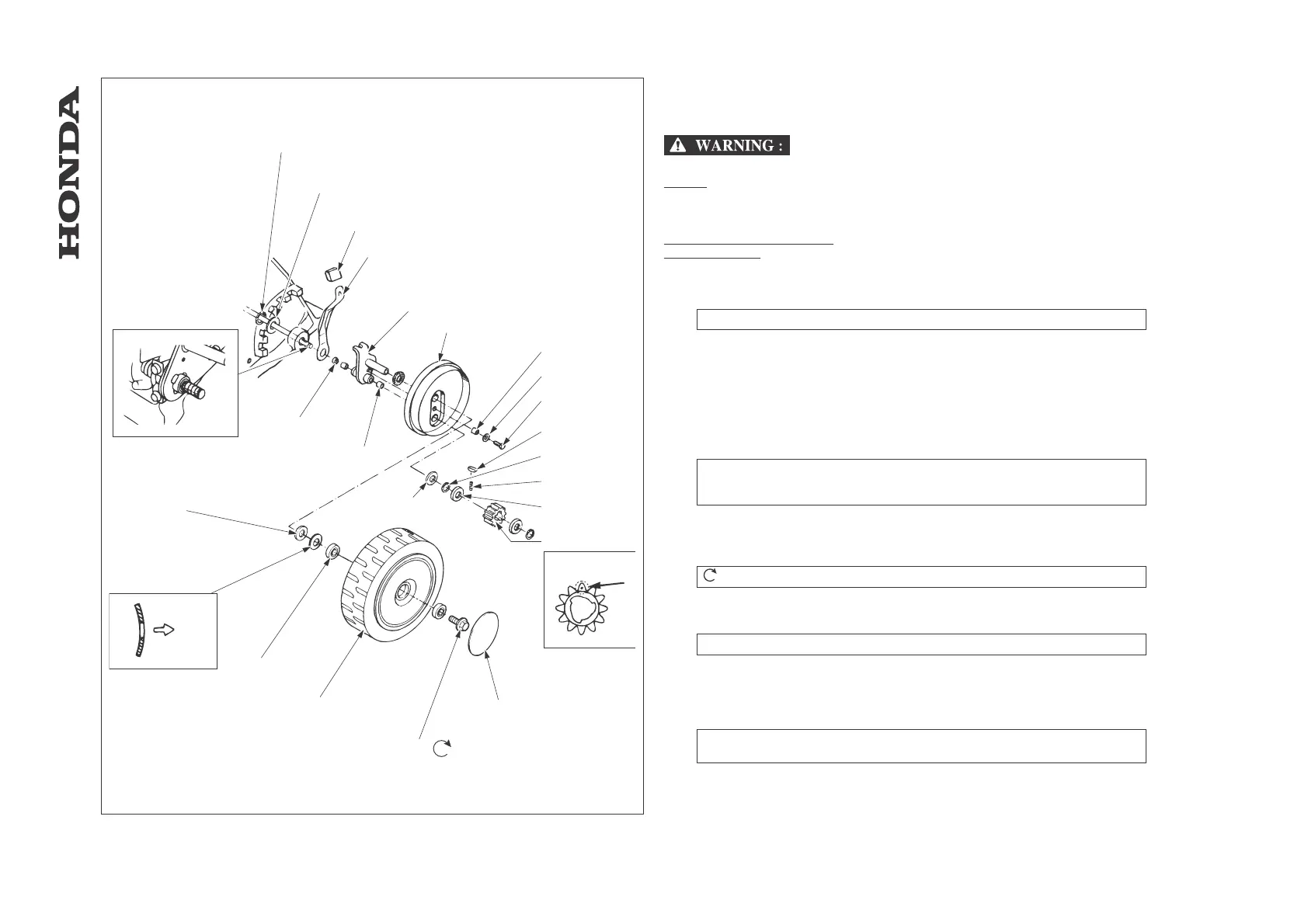

13.2 Rear wheel

a. Disassembly / Reassembly

Wear heavy gloves to protect your hand when servicing near the blade.

NOTE:

The rear wheel servicing can be done with the engine on the cutter housing.

Place the mower on wooden blocks and support the housing securely. Do not turn upside

down.

HRD535/K1 except Q type

HRD536/K1/K2

[1] REAR ADJUSTER LEVER (2)

[2] ADJUSTER GRIP (2)

[3] REAR ADJUSTER ARM (2)

REASSEMBLY: Apply grease to the inside before installing.

[4] WHEEL COVER (2)

[5] COLLAR (2)

[6] WASHER, 5 mm (2)

[7] PAN SCREW,5x12mm(2)

[8] THRUST WASHER, 13 mm (2)

[9] SNAP RING (4)

[10] RATCHET RETURN SPRING (2)

[11] PINION GEAR COLLAR

[12] PINION GEAR (2)

REASSEMBLY: Install with punch mark facing:

LEFT: inside

RIGHT: outside

[12]-1 PUNCH MARK

[13] RATCHET KEY (2)

[14] REAR WHEEL CAP (2)

[15] WHEEL SCREW,8x12mm(2)

TIGHTNING TORQUE: 24 N.m

[16] WHEEL BEARING (4)

[17] REAR WHEEL ASSEMBLY (2)

[18] WHEEL WASHER (2)

REASSEMBLY: Install the washer as shown.

[18]-1 WHEEL SIDE

[19] THRUST WASHER (2)

[20] BUSHING (4)

[21] SEAL (2)

[22] AXLE SHAFT GROOVE

REASSEMBLY: Apply transparent tape over axle grooves to protect seal when

inserting the rear adjuster arm.

[23] PLAIN WASHER, 22 mm (2)

[24] SNAP RING, 22 mm (2)

-84-

HRA536 - HRD535 - HRD536

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[12]-1

[13]

[14]

[15]

[16]

[17]

[18]

[18]-1

[19]

[20]

[21]

[22]

[23]

[24]

24

- FRONT WHEEL / REAR WHEEL

Loading...

Loading...