MICROPROCESSOR-BASED/DDC FUNDAMENTALS

138

ENGINEERING MANUAL OF AUTOMATIC CONTROL

The use of preprogrammed operators saves time when writing

control sequences and makes understanding of the control

sequence the equivalent of reading a pneumatic control diagram.

Programming schemes often allow program operators to be

selected, positioned, and connected graphically. The alternative

to using preprogrammed operators is to write an equivalent

control program using the programming language furnished

for the controller.

ENERGY MANAGEMENT SOFTWARE

Microprocessor-based controllers can combine control and

energy management functions in the controller to allow sensor

and data file sharing and program coordination. Energy

management functions can be developed via the above DDC

operators, math functions, and time clock values, or they can

be separate program subroutines.

A summary of energy management programs possible for

integration into microprocessor-based controllers follows:

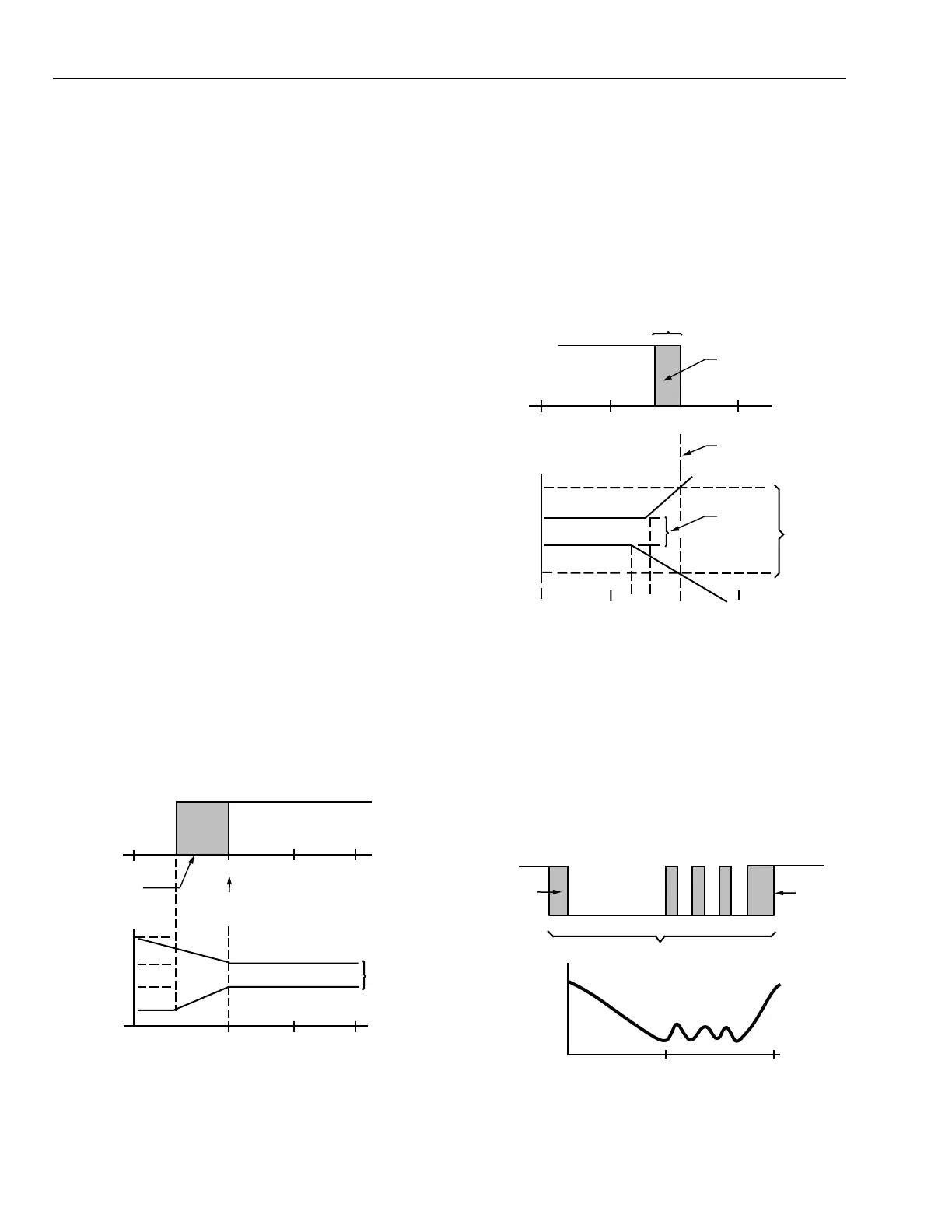

Optimum Start

Based on measurements of indoor and outdoor temperatures

and a historical multiplier adjusted by startup data from the

previous day, the optimum start program (Fig. 5) calculates a

lead time to turn on heating or cooling equipment at the

optimum time to bring temperatures to proper level at the time

of occupancy. To achieve these results the constant volume AHU

optimum start program delays AHU start as long as possible,

while the VAV optimum start program often runs the VAV AHU

at reduced capacity. Unless required by IAQ, outdoor air

dampers and ventilation fans should be inactive during

preoccupancy warmup periods. For weekend shutdown periods,

the program automatically adjusts to provide longer lead times.

This program adapts itself to seasonal and building changes.

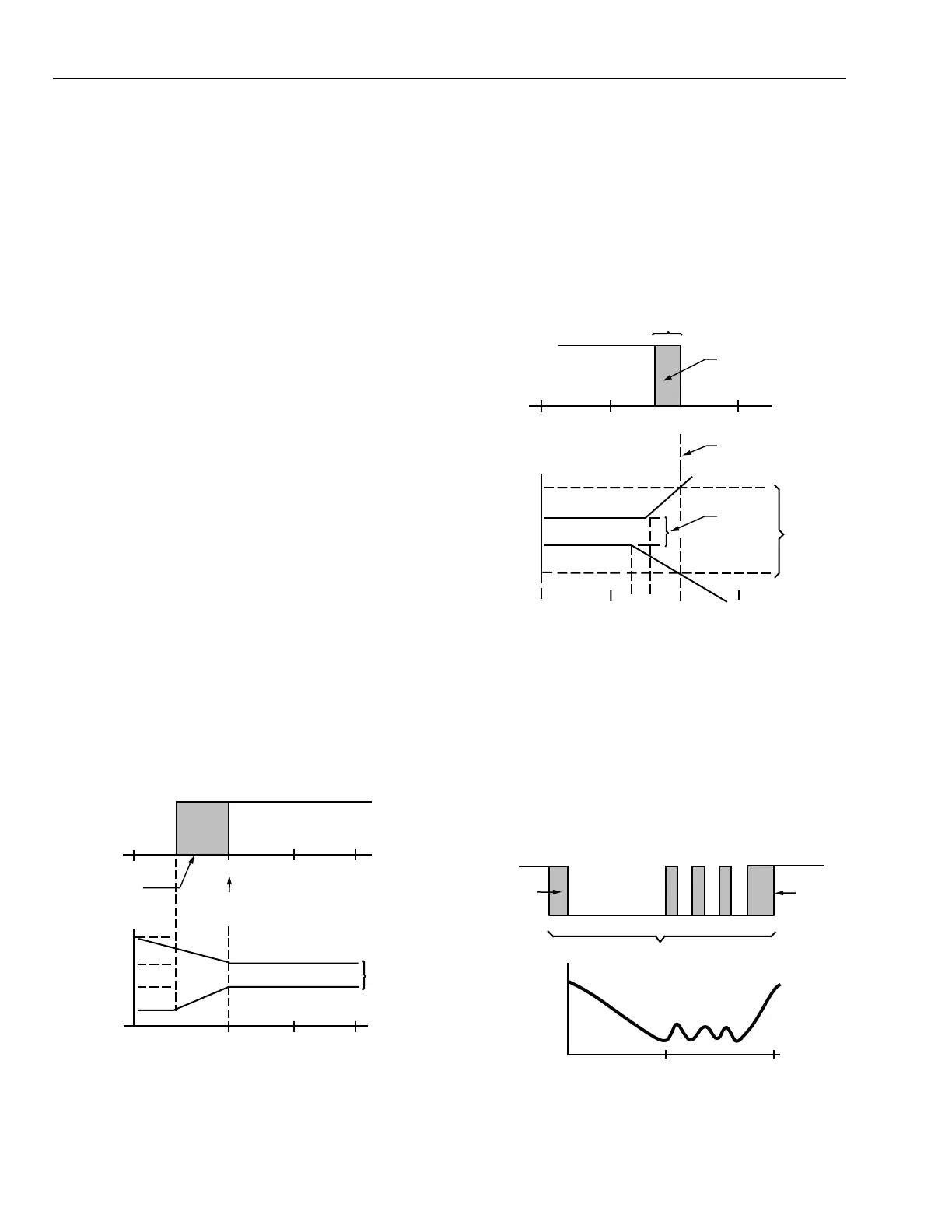

Optimum Stop

The optimum stop program (Fig. 6) uses stored energy to

handle the building load to the end of the occupancy period.

Based on the zone temperatures that have the greatest heating

and greatest cooling loads, and the measured heating and

cooling drift rates, the program adjusts equipment stop time to

allow stored energy to maintain the comfort level to the end

of the occupancy period. This program adapts itself to

changing conditions.

Fig. 5. Optimum Start.

Fig. 6. Optimum Stop.

Night Cycle

The night cycle program (Fig. 7) maintains a low temperature

limit (heating season) or high temperature limit (cooling season)

during unoccupied periods by cycling the air handling unit while

the outdoor air damper is closed. Digital control systems often

reduce fan capacity of VAV AHU systems to accomplish this

and reduce energy usage.

Fig. 7. Night Cycle.

AHU ON

AHU OFF

6:00 AM

8:00 AM 10:00 AM

12:00 NOON

NORMAL

OCCUPANCY

ADAPTIVELY

ADJUSTED

LEAD TIME

INDOOR

TEMPERATURE (°C)

27

24

21

18

6:00 AM

8:00 AM 10:00 AM 12:00 NOON

TIME

COOLING

HEATING

COMFORT

LEVEL

C4311

AHU ON

AHU OFF

3:00 PM

4:00 PM

6:00 PM

END OF

OCCUPANCY

INDOOR

TEMPERATURE (°C)

24

23

22

21

4:00 PM

C4312

OPTIMUM STOP

PERIOD

3:00 PM

6:00 PM

TIME

NORMAL

CONTROL

RANGE

COMFORT

LIMITS

5:00 PM

5:00 PM

LEAD TIME

OF SHUTDOWN

SUMMER

WINTER

AHU ON

AHU OFF

5:00 PM

12:00 MIDNIGHT

8:00 AM

OPTIMUM

STOP

PERIOD

M15137

UNOCCUPIED PERIOD

INDOOR

TEMPERATURE (°C)

22

18

16

5:00 PM 12:00 MIDNIGHT 8:00 AM

4:30 PM

OPTIMUM

START

PERIOD

Loading...

Loading...