ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

379

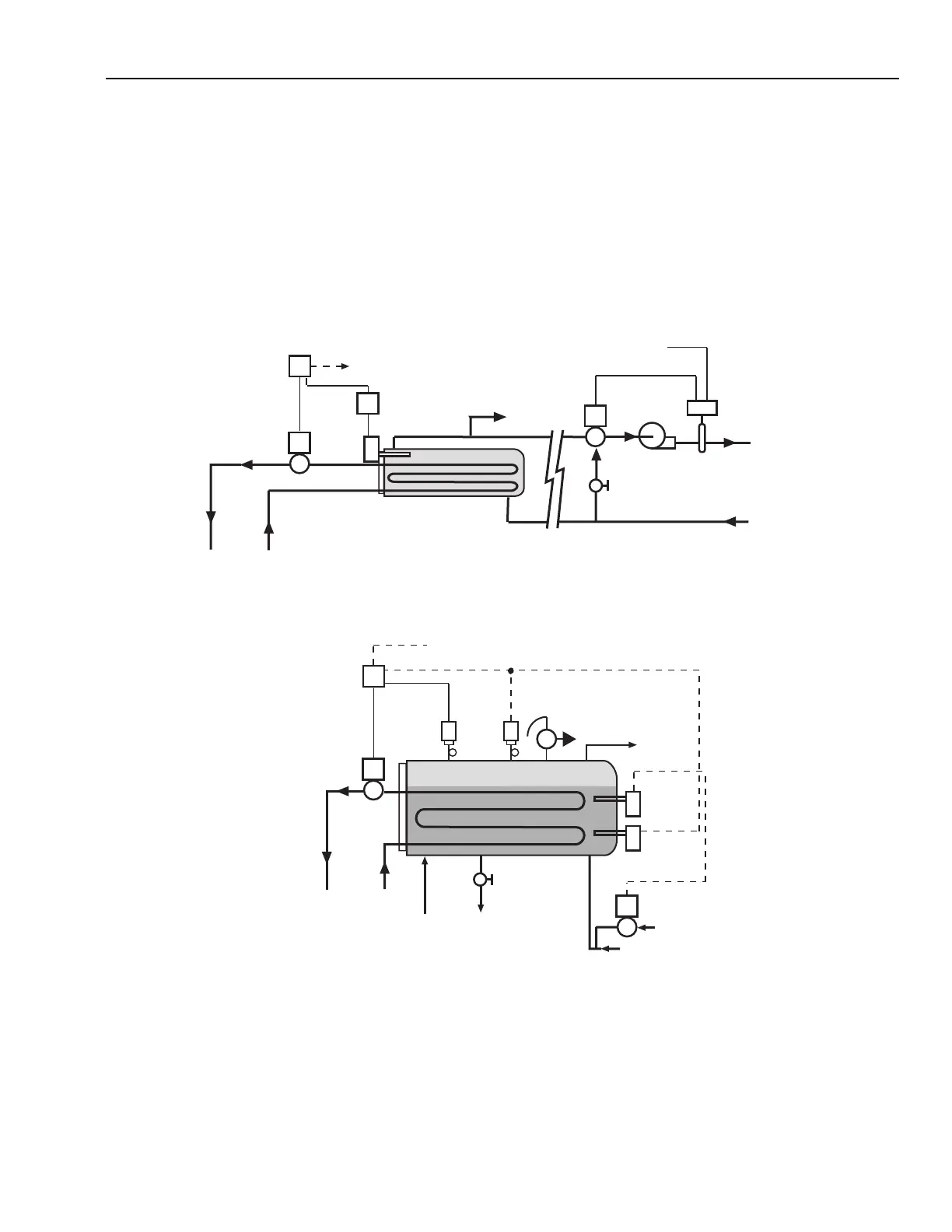

C2588

RELAY

CLOSES

VALVE IF

SAFETY

LIMITS

EXCEEDED

HIGH

TEMPERATURE

WATER VALVE

HTWR HTWS

STORAGE

CONVERTER

STEAM

MAKE UP

WATER

LEVEL

CONTROL

LOW

WATER

CUT OFF

MAKE UP

WATER

CONDENSATE

RETURN

STEAM

GENERATOR

BLOWDOWN

AND DRAIN

FEED

INLET

RELIEF

VALVE

PRESSURE

HIGH LIMITPRESSURE

CONTROL

OPTIONAL

ALARM

HTW STEAM GENERATORS

Using the central HTW boilers for steam production is not

recommended. The HTW system is best used to produce steam

by locating steam generators at the point of need.

The steam generator (Fig. 125) is designed so that the

minimum water level covering the tubes takes up 60 percent or

less of the volume of the shell. The remaining 40 percent for

steam is sufficient to avoid water carry over. A water eliminator

at the steam exit removes most water from the steam.

Flash converters convert HTW to steam by reducing the

pressure. They are not satisfactory steam generators because

water is carried with the steam and control is less stable.

Control of a steam generator is simpler because pressure

changes are sensed immediately and corrections in valve position

are made quickly to maintain the desired steam pressure.

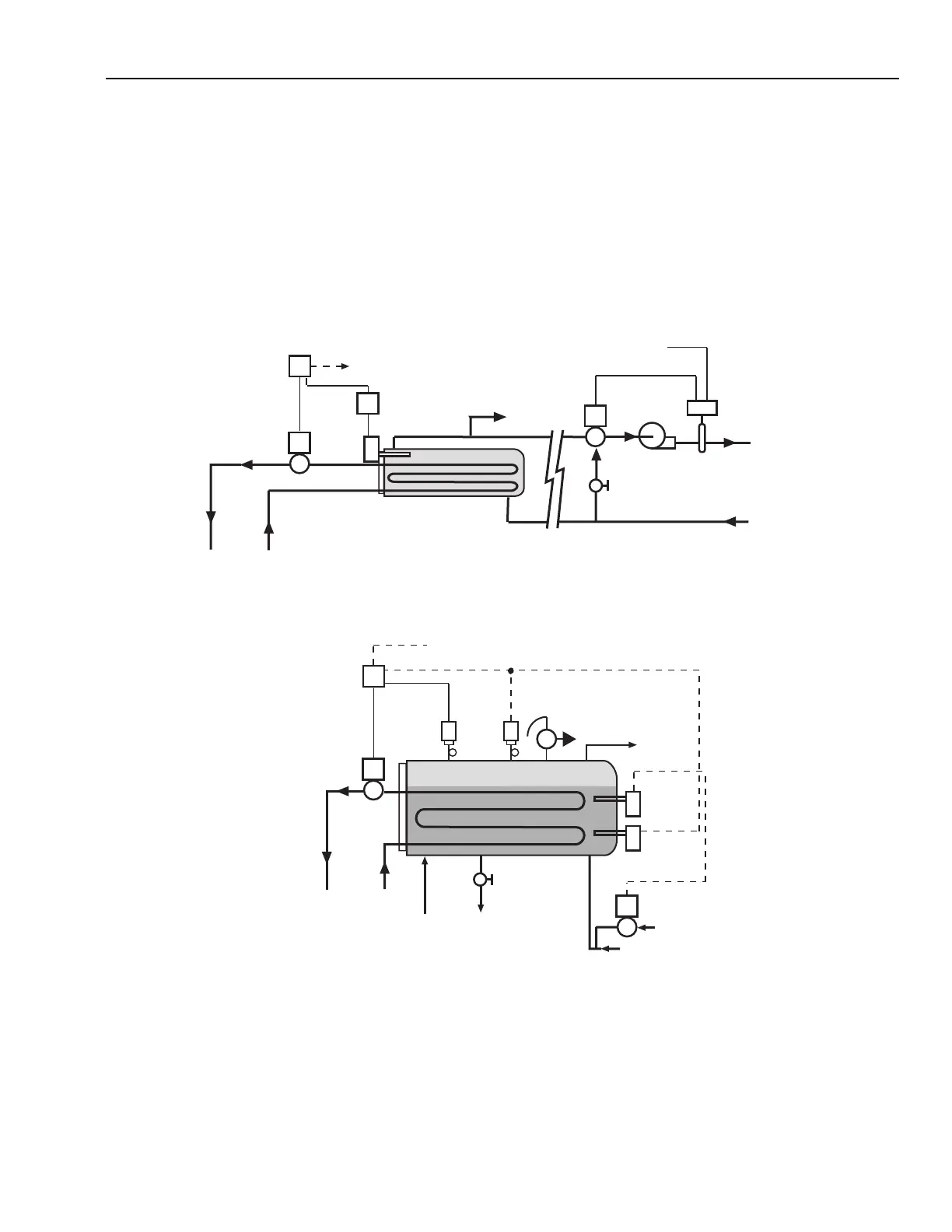

Fig. 124. HTW to HW Multizone Storage Converter.

Fig. 125. Steam Generator Using HTW.

C4627

RELAY CLOSES

VALVE WHEN PUMP STOPS

(NOT REQUIRED TO

PREVENT FLASHING)

HIGH TEMPERATURE

WATER VALVE

HTWR HTWS

STORAGE

CONVERTER

HOT WATER

TEMPERATURE

CONTROL

TO PUMP INTERLOCK

AND/OR OUTDOOR

CONTROLLER

TO HOT WATER

CONVERTER

RESET SIGNAL

FROM OUTDOOR

CONTROLLER

HOT WATER

3-WAY ZONE

VALVE

PUMP

MANUAL

BALANCING

VALVE

TYPICAL ZONE

HWR

HWS

45-95˚C

ZONE WATER

TEMPERATURE

CONTROLLER

Loading...

Loading...