ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

328

Fig. 41. Boiler Ratings and Efficiency.

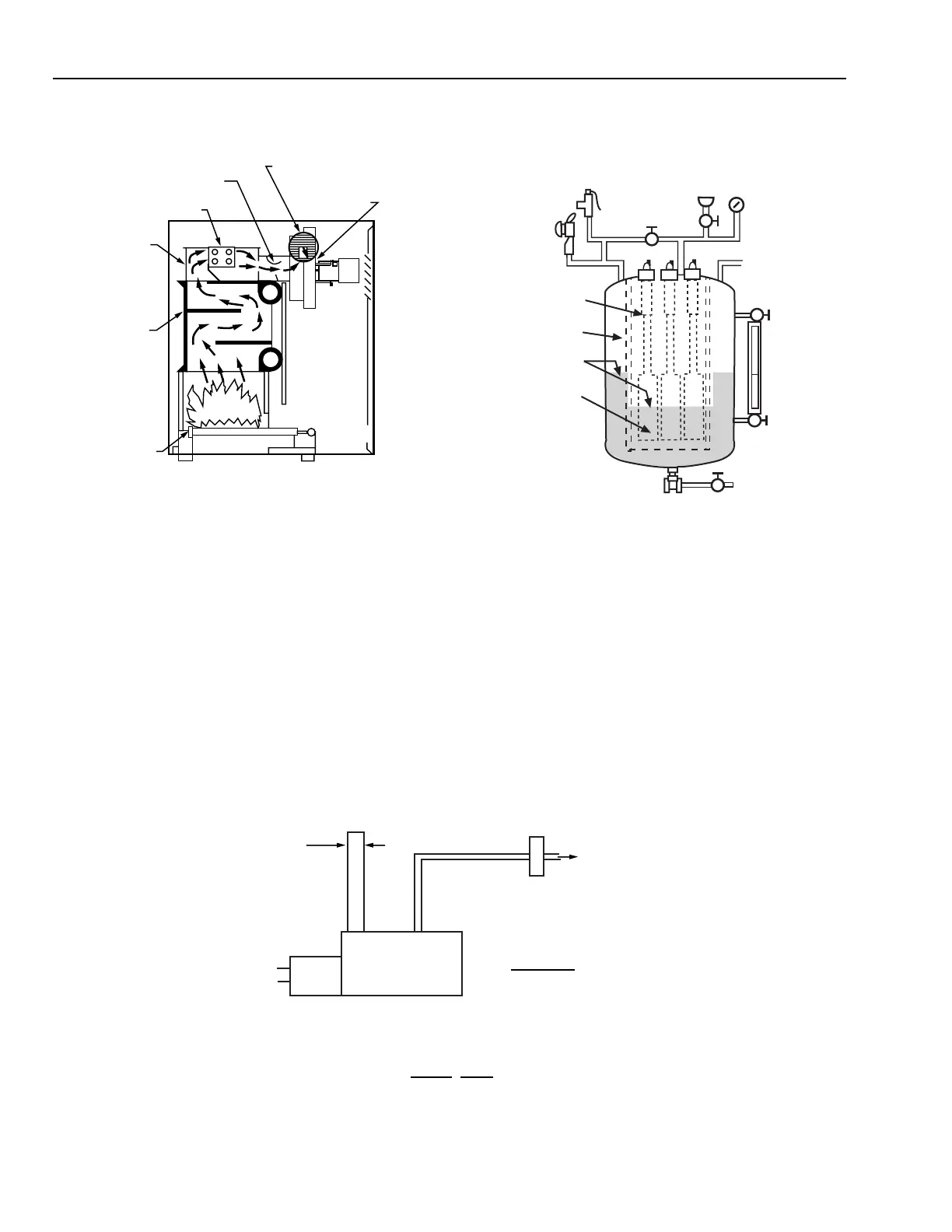

Some modular boilers have very small storage capacity and

very rapid heat transfer so water flow must be proven before

the burner is started.

BIOLER

SECTIONS

BURNER

M15055

FLUE GAS

COLLECTOR

HEAT

EXCHANGER

FLUE GAS

CLOSE-OFF

SIDE

OUTLET

BLOWER

ASSEMBLY

GENERATING

CHAMBER

REGULATING

CHAMBER

WATER

LEVEL

ELECTRODES

C2901

Fig. 39. High Efficiency Modular Boiler.

ELECTRIC BOILERS

Electric boilers heat water or produce steam by converting

electrical energy to heat using either resistance elements or

electrodes. Electric boilers are considered to be 100 percent

efficient since all power consumed, directly produces hot water

or steam. Heat losses through the jacket and insulation are

negligible and there is no flue.

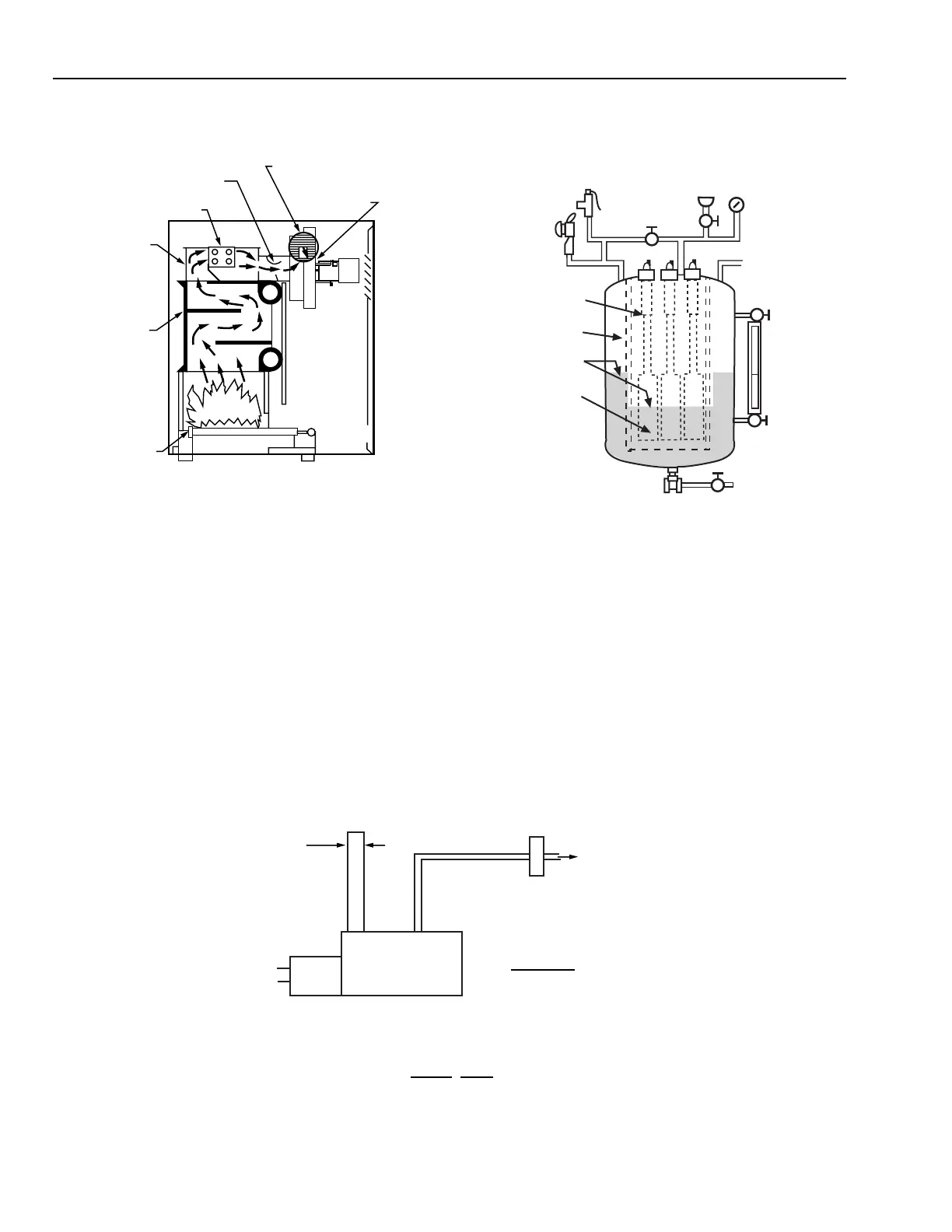

Electrode boilers (Fig. 40) have electrodes immersed in the

water. Current passes through the water between electrodes

and the resistance of the water generates heat. Electrode boilers

are available in sizes up to 11,000 kW. Resistance boilers have

the resistance (heating) elements immersed in but electrically

insulated from the water and are manufactured in sizes up to

3000 kW.

Electric elements and electrodes are grouped to provide four

or more stages of heating. A step controller responding to steam

pressure or hot water temperature activates each stage of heating

as required to heat the building.

Fig. 40. Electrode Steam boiler.

BOILER RATINGS AND EFFICIENCY

Boilers can be rated in several ways. Figure 41 shows

commonly used ratings and terms. Boiler input rate is in

kilowatts (kW). Input ratings are usually shown on the boiler

(or burner) nameplate. The boiler output rate is given in grams

per second (g/s).

Gross efficiency is output (steam or water heat content and

volume) divided by fuel input (measured by a fuel meter at

steady-state firing conditions). The efficiency as indicated by

flue gas conditions does not take into account jacket and piping

losses so is usually higher than the gross efficiency.

FLUE GAS:

6% OXYGEN

300°C STACK

TEMPERATURE

80% EFFICIENCY

STEAM BOILER

STACK

DUAL

BURNERS

OIL

GAS

200 kPa

STEAM

METER

INPUT:

NATURAL GAS: 15.8 L/s AT 37 kJ/L

586 kW

#2 OIL: 0.9 L/s

OUTPUT:

kW= 441.5

GJ/h= 1.589

STEAM: KILOGRAMS PER HOUR OR

GRAMS PER SECOND

C4089

441 389 J/s

2 325 800 J/kg

POWER: 441 kW

=

=

0.1898 kg/s

190 g/s (683 kg/h)

GROSS EFFICIENCY = OUTPUT = 441 kW

X 100 = 75.26 ≈ 75%

INPUT 586 kW

Loading...

Loading...