ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

360

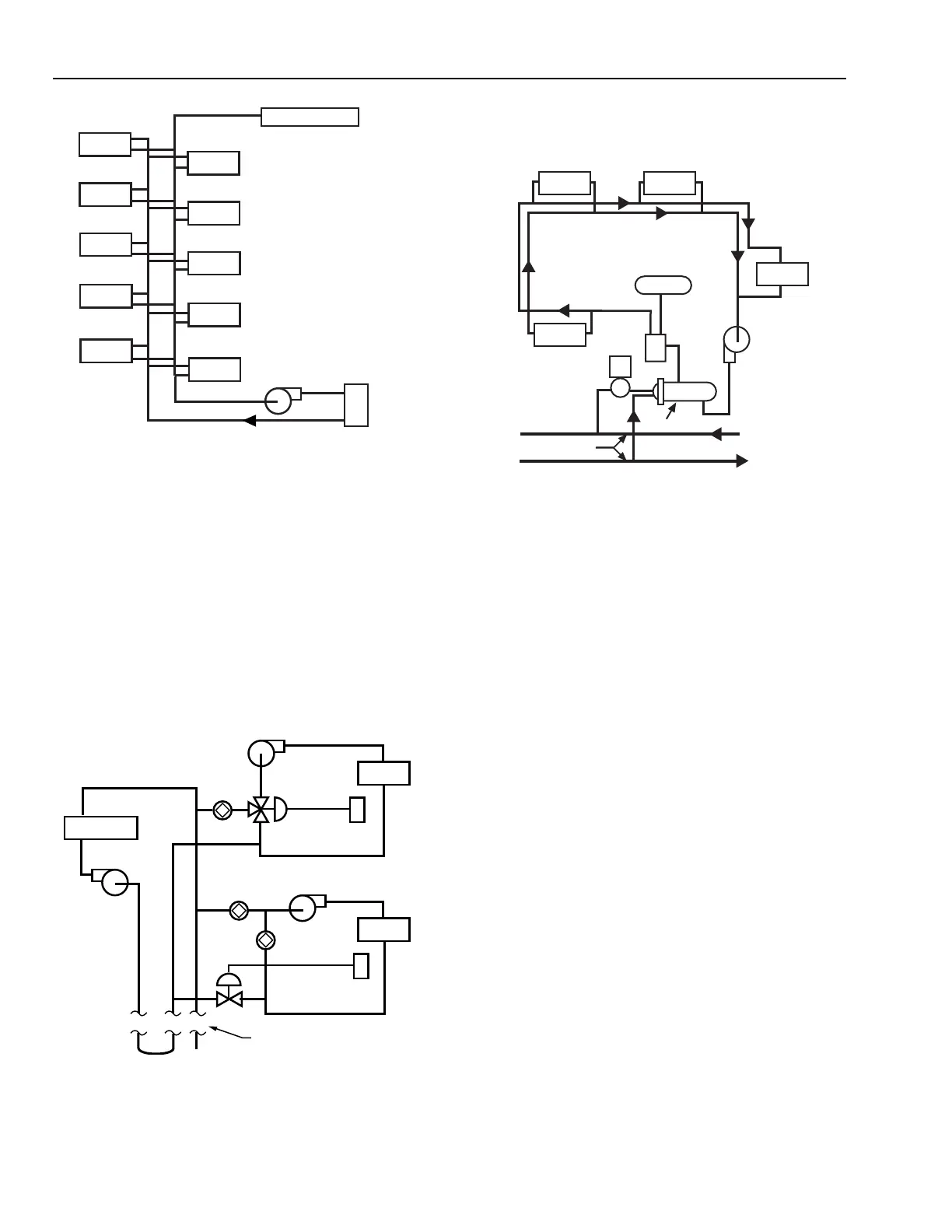

Fig. 87. Two-Pipe Direct-Return System.

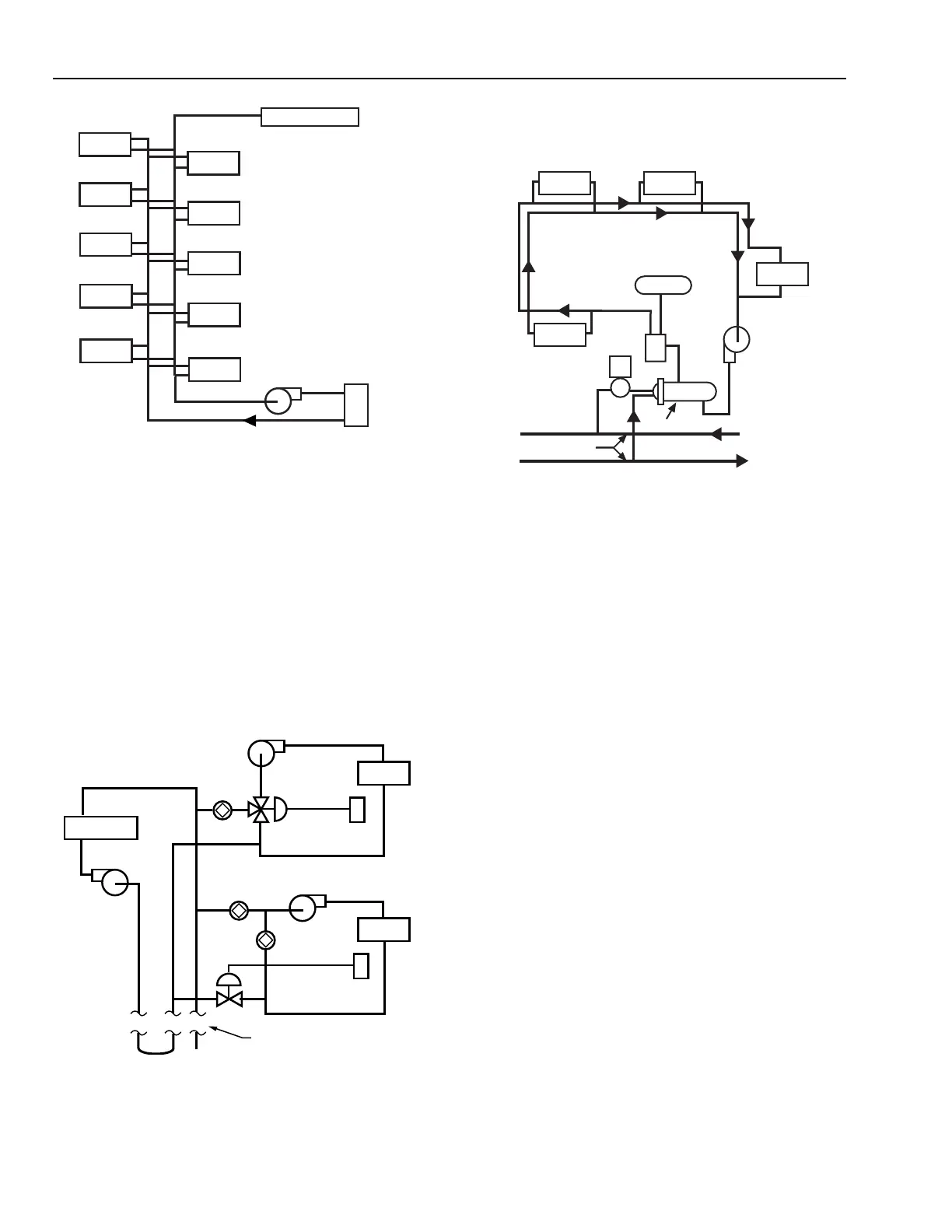

Primary-Secondary Pumping

Primary-secondary pumping allows water temperature and

on/off times of each secondary zone to be independently

controlled. The main supply pump uses less power in this

arrangement since it is sized to handle only main pressure losses.

Secondary pumps handle only the zone piping losses.

Figure 88 shows common configurations for primary-

secondary pumping. The three-way valve configuration

provides more positive control than the two-way valve.

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

EXPANSION TANK

BOILER

OR

CHILLER

SUPPLY

RETURN

C2835

Fig. 88. Piping for Primary-Secondary Pumping.

BOILER

LOAD

LOAD

T

T

PRIMARY

PUMP

ZONE PUMP

ROOM

THERMOSTAT

ROOM

THERMOSTAT

ZONE WITH 2-WAY VALVE

OTHER

ZONES

ZONE WITH 3-WAY VALVE

BALANCING

VALVE

ZONE PUMP

M10485

A converter (heat exchanger) shown in Figure 89 can be used

in large or high rise buildings to reduce the zone temperature/

pressure requirements from those of the mains.

EXPANSION TANK

CONVERTER

HIGH OR MEDIUM

TEMP MAINS

RETURN

SUPPLY

C2915-1

LOAD

LOAD

LOAD

LOAD

Fig. 89. Converter Used to Supply

Zones from a Larger System.

CONTROL OF HOT WATER SYSTEMS

General

Heating (terminal) units used in hot water heating systems are:

— Radiant Panels

— Radiators or finned tubes

— Forced air heating coils

Control of heat output from a heating unit can use one or a

combination of the following methods:

— On-off control, by starting and stopping a pump or

opening and closing a valve

— Modulating flow control

— Supply water temperature control

Modulating Flow Control

Varying water flow to finned tube radiation or a heating coil,

each supplied with constant temperature hot water, is shown

graphically in Figures 90 and 91.

In both cases, reducing flow 75 percent reduces the heat

output only 30 percent because as flow is reduced, more heat is

extracted from each liter of water. At low flows leaving water

temperature decreases sharply (Fig. 91). At light loads

modulating flow control by itself is not the best means of

controlling heat output.

Loading...

Loading...