ENGINEERING MANUAL OF AUTOMATIC CONTROL

VALVE SELECTION AND SIZING

437

The close-off pressure in a diverting valve equals the

maximum value of the inlet pressure minus the minimum value

of the downstream pressure.

Globe diverting valves must not be used for mixing service.

As with mixing valves used for diverting service, media pressure

drop across the valve can cause it to slam shut with resulting

loss of control.

EXAMPLE:

A diverting valve application has 140 kPa maximum on

the inlet port, one outlet port discharging to the

atmosphere, and the other outlet port connecting to a tank

under 70 kPa constant pressure. The pressure difference

between the inlet and the first outlet port is 140 kPa and

between the inlet and second outlet port is 70 kPa. The

application requires a diverting valve with at least 140 kPa

close-off rating.

VALVE SIZING

Every valve has a capacity index or flow coefficient (K

v

).

Typically determined for the globe and ball valves at full open

and about 60 degrees open for butterfly valves. K

v

is the quantity

of water in cubic meters per hour between 5 and 40°C that

flows through a valve with a pressure differential of 10

5

pascals.

Sizing a valve requires knowing the medium (liquid or gas)

and the required pressure differential to calculate the required

K

v

. When the required K

v

is not available in a standard valve,

select the next closest and calculate the resulting valve pressure

differential at the required flow to verify to verify acceptable

performance.

After determination of the valve K

v

, calculation of the flow

of any medium through that valve can be found if the

characteristics of the medium and the pressure drop across the

valve are known.

WATER VALVES

Determine the capacity index (Kv) for a valve used in a water

application, using the formula:

Determining the K

v

of a water valve requires knowing the

quantity of water (m

3

/h) through the valve and the pressure

drop (∆P) across the valve. If the fluid is a glycol solution, use

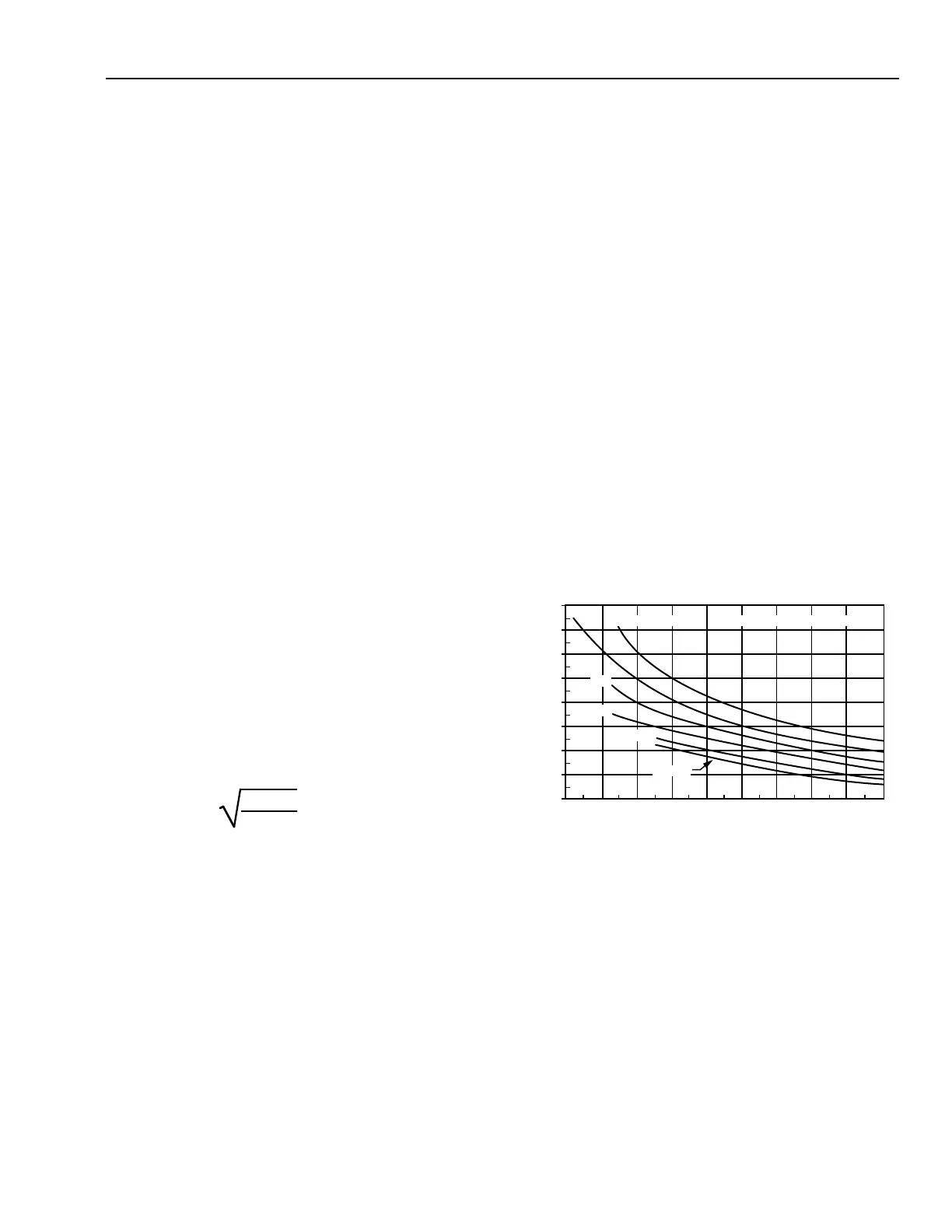

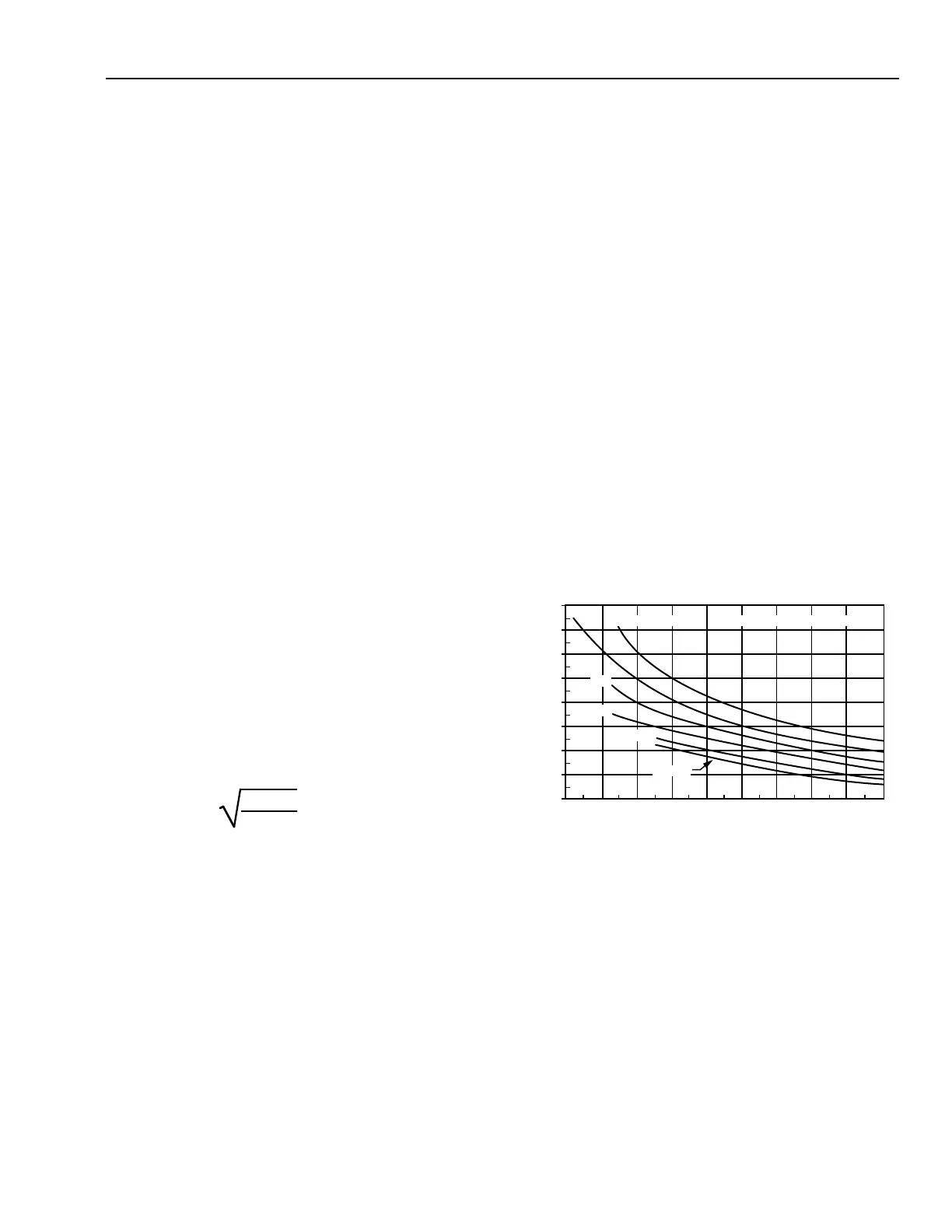

the pressure drop multipliers from either Figure 14 or 15. See

the sections on QUANTITY OF WATER and WATER VALVE

PRESSURE DROP. Then select the appropriate valve based

on K

v

, temperature range, action, body ratings, etc., per VALVE

SELECTION guidelines.

REPRINTED BY PERMISSION FROM ASHRAE HANDBOOK—

1996 HVAC SYSTEMS AND EQUIPMENT

K

v

=Q

ρ

∆P • 10

Where:

Q = Flow of fluid in cubic meters per hour

required to pass through the valve.

ρ = Specific gravity of the fluid (water =

1000 kg/m

3

).

∆P = Pressure drop in kPa. See Figures 14 and 15

for glycol solution correction values.

Fig. 14. Pressure Drop Correction for

Ethylene Glycol Solutions.

-20 -10 0 10 20 30 40 50 60 70

PRESSURE DROP CORRECTION FACTOR

TEMPERATURE, °C

M15319

40%

10%

20%

30%

WATER

50% BY MASS

0.8

0.9

1.1

1.3

1.5

1.0

1.2

1.4

1.6

ETHYLENE GLYCOL SOLUTION

Loading...

Loading...