ENGINEERING MANUAL OF AUTOMATIC CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

244

WATER COIL FACE AND BYPASS SYSTEM CONTROL

Functional Description

The following results are obtained:

Item

No. Explanation

1 Mixed air temperature at cooling design

condition.

2 Air entering the cooling coil is cooled along a

line of constant moisture content until saturation

is approached. Near saturation the moisture con-

tent is reduced as the air is cooled. This process

involves both latent and sensible cooling.

3 The final leaving air temperature necessary to

satisfy space requirements will be maintained

by reheating along a constant moisture line.

4 Heating coil discharge.

5 This process line represents the increase in

temperature and humidity that occurs due to

the sensible and latent heat gains in the space.

Item

No. Function

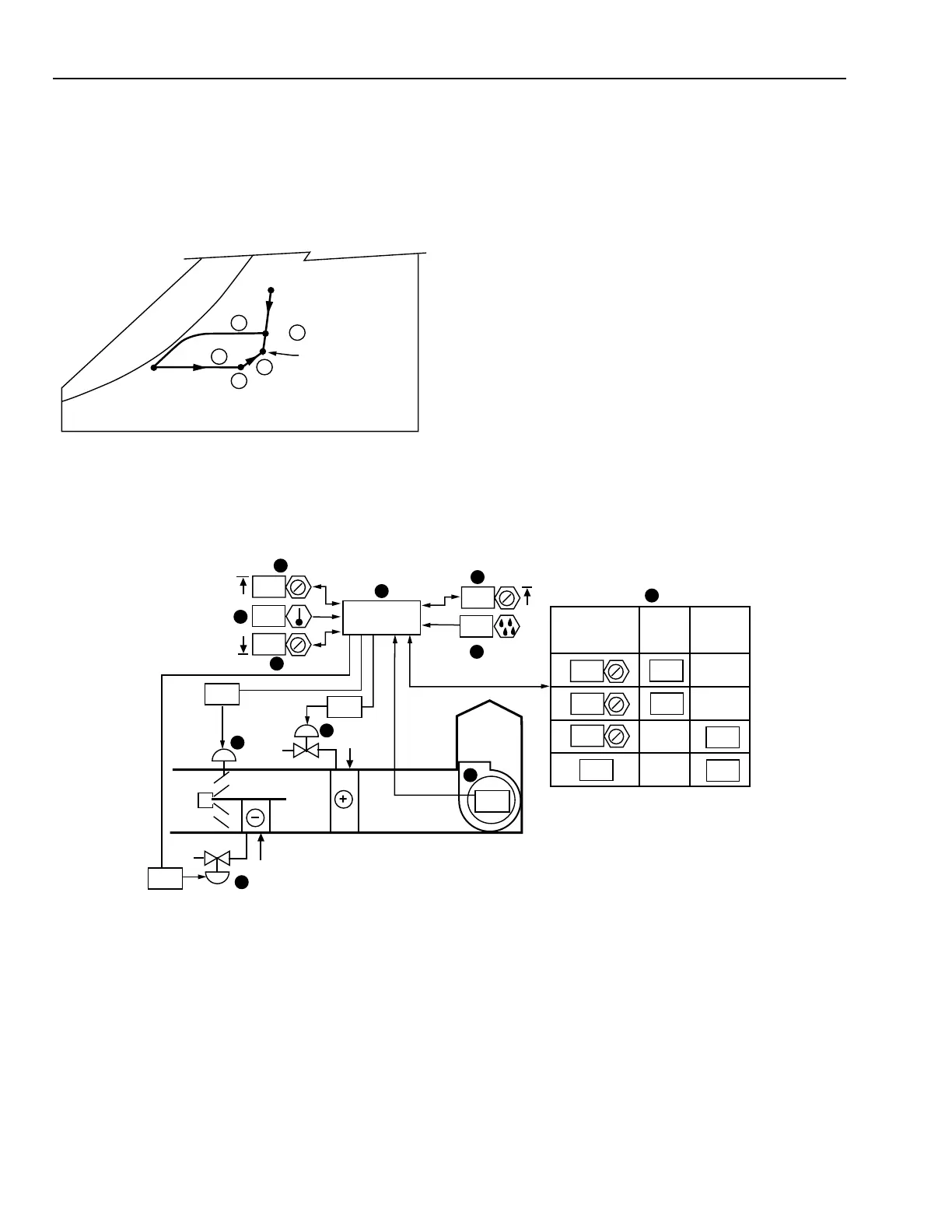

1 Control system energizes when fan is turned

on (See FAN SYSTEM START-STOP

CONTROL).

2-4 Space temperature PI control loops have heat

and cool setpoints with deadband.

5,6 Space humidity sensor and setpoint enable

dehumidification.

7-9 Heating and cooling valves and face and

bypass dampers position for heating, cooling,

and dehumidifying cycles.

10 Stages chilled water and face-and-bypass

damper loading.

11 Control program coordinates cooling, heating,

dehumidifying, and fan and hot water

interlock control.

In the following chart it is assumed that:

1. Desired space condition is 24°C DB and a maximum of

50% RH.

2. OA condition is 27°C DB and 26°C WB.

3. Air entering the system is from the ECONOMIZER

CYCLE DECISION application. The system operates on

25 percent OA during the cooling cycle.

4. Cooling coil leaving air temperature is 13°C.

M15174

SA

11

6

5

2

70

90

32

SUPPLY

FAN

COOL

HEAT

ON

1

CONTROL

PROGRAM

3

4

7

9

25

50

50

22

23.5

MA

8

10

0

60

10

100

COOL OR

DEHUMIDIFIER

DEMAND

CHW

VALVE

0

100

0

100

FACE

DAMPER

C3253

RA 24°C DB,

50% RH

MA

OA 27°C DB,

26°C WB

1

2

3

5

4

COOLING COIL

DISCHARGE

13°C DB

Loading...

Loading...