PNEUMATIC CONTROL FUNDAMENTALS

ENGINEERING MANUAL OF AUTOMATIC CONTROL

65

construction (Fig. 10) and are used to amplify, reverse, average,

select, and switch controller outputs before being sent to valve

and damper actuators.

AIR COMPRESSOR

The air compressor provides the power needed to operate

all control devices in the system. The compressor maintains

pressure in the storage tank well above the maximum required

in the control system. When the tank pressure goes below a

minimum setting (usually 480 to 620 kPa), a pressure switch

starts the compressor motor. When the tank pressure reaches a

high-limit setting, the pressure switch stops the motor. A

standard tank is typically large enough so that the motor and

compressor operate no more than 50 percent of the time, with

up to twelve motor starts per hour.

AIR DRYER

MOTOR

INTAKE FILTER

COMPRESSOR

PRESSURE SWITCH

HIGH PRESSURE SAFETY RELIEF VALVE

DRIVE BELT

STORAGE

TANK

NORMALLY OPEN

SERVICE/TEST VALVE

NORMALLY CLOSED

SERVICE/TEST VALVE

C2617-2

HIGH-PRESSURE

GAGE

DRAIN

COCK

PRESSURE

REDUCING

VALVE

SAFETY REFIEF VALVE

LOW-PRESSURE GAGE

MAIN AIR

TO SYSTEM

TEST COCK

TEST COCK

AUTO TRAP

AUTO

SEPARATOR

FILTER/TRAP

SERVICE

BYPASS

VALVE

PIPED TO DRAIN

SUBMICRON

FILTER

Fig. 11. Typical Air Supply.

The controlling pressure is connected at the pilot port (P),

and pressures to be switched are connected at the normally

connected port (O) or the normally disconnected port (X). The

operating point of the relay is set by adjusting the spring pressure

at the top of the relay.

When the pressure at the pilot port reaches the relay operating

point, it pushes up on the diaphragm in the control chamber

and connects pressure on the normally disconnected port (X)

to the common port as shown. If the pilot pressure falls below

the relay setpoint, the diaphragm moves down, blocks the

normally disconnected (X) port, and connects the normally

connected port (O) to the common port.

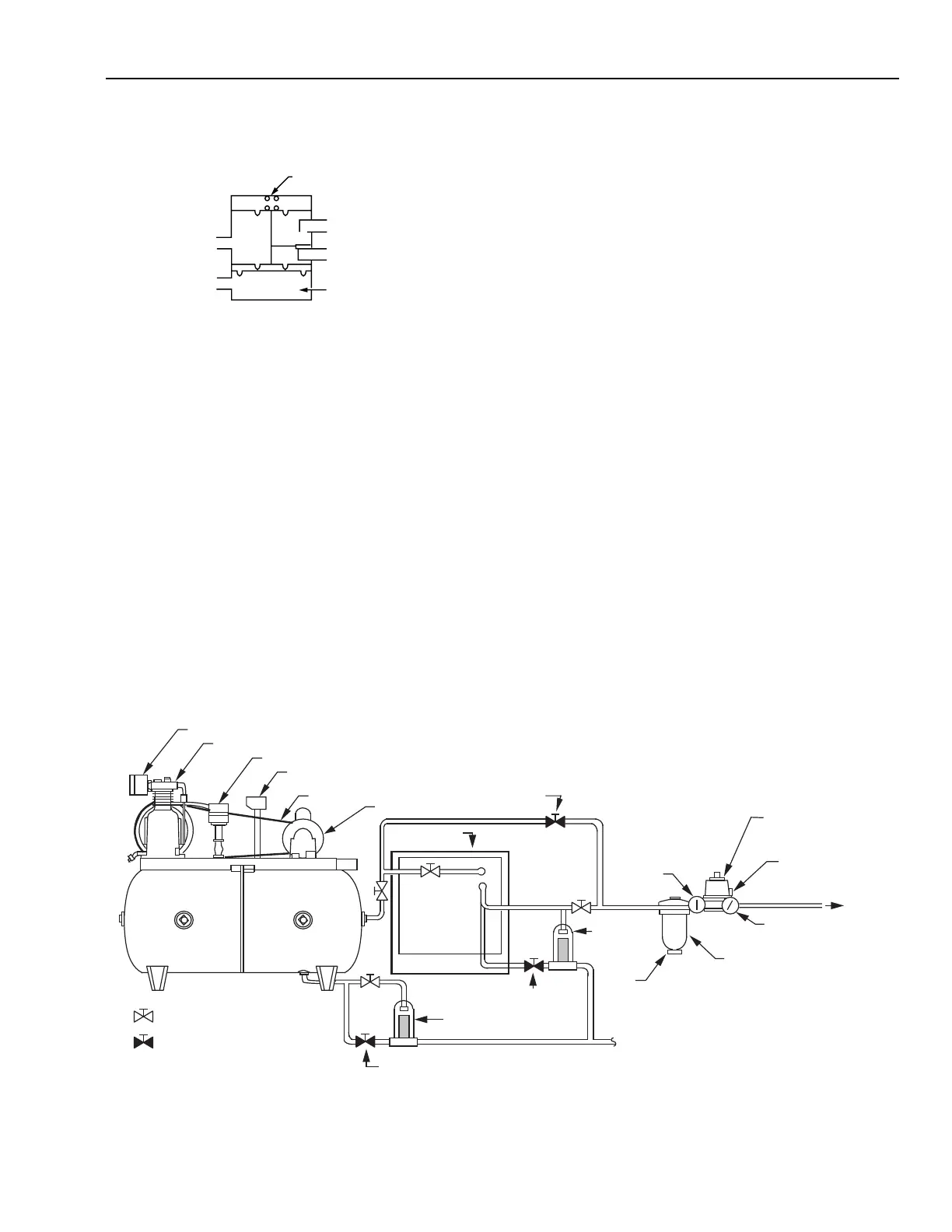

AIR SUPPLY EQUIPMENT

GENERAL

A pneumatic control system requires a supply of clean, dry,

compressed air. The air source must be continuous because

many pneumatic sensors, controllers, relays, and other devices

bleed air. A typical air supply system includes a compressor,

an air dryer, an air filter, a pressure reducing valve, and air

tubing to the control system (Fig. 11).

The following paragraphs describe the compressor, filter,

pressure reducing valves, and air drying techniques. For

information on determining the moisture content of compressed

air, refer to the General Engineering Data section.

COMMON

PORT

P

PILOT

PORT

CONTROL

CHAMBER

X

O

NORMALLY

CONNECTED PORT

NORMALLY

DISCONNECTED PORT

C2608

SPRING

Fig. 10. Typical Switching Relay.

Loading...

Loading...