ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

368

STEAM DISTRIBUTION SYSTEMS

STEAM PIPING MAINS

Steam piping mains must carry steam to all parts of the

system allowing a minimum amount of condensate (heat loss)

to form, must provide adequate means to collect the condensate

that does form, and must prevent water pockets that can cause

water hammer.

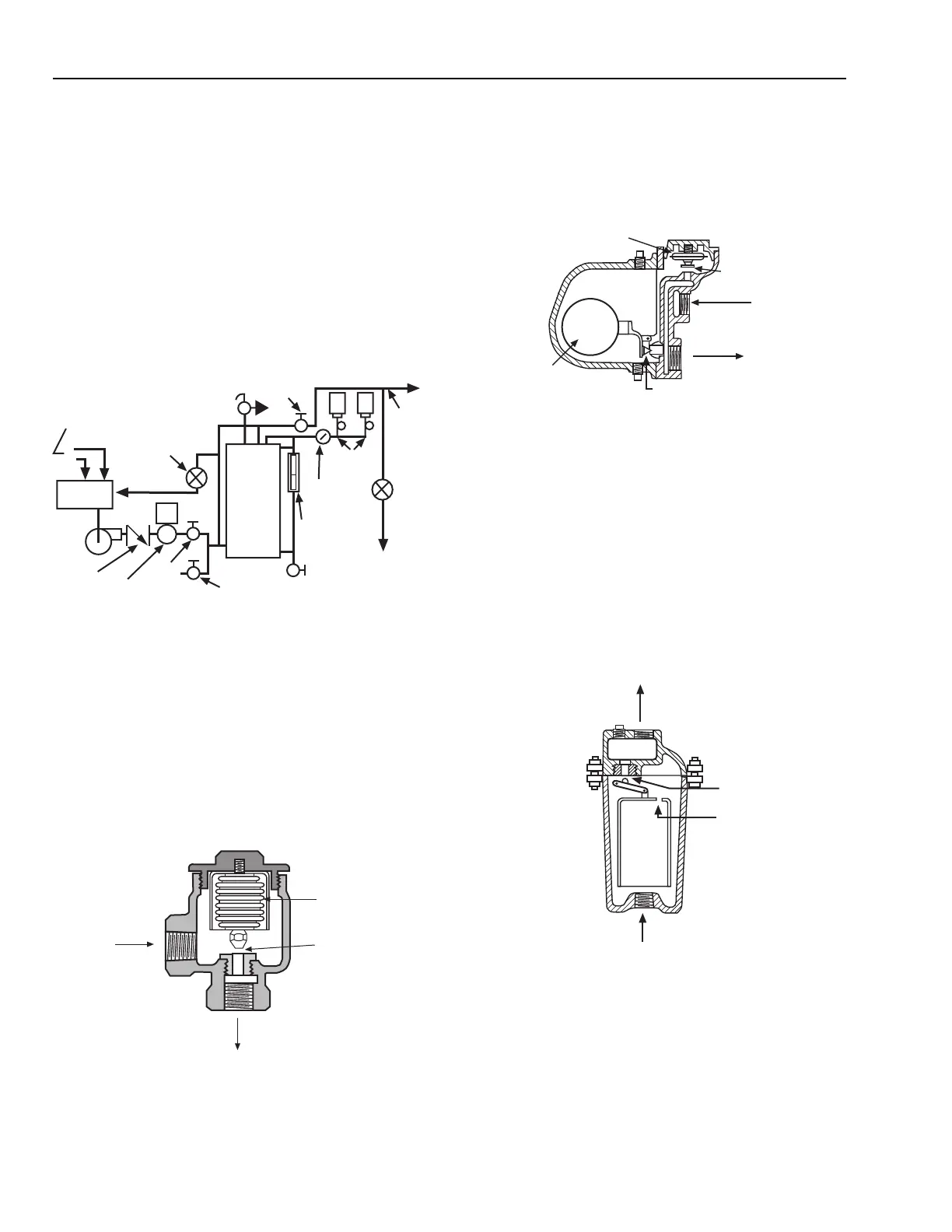

Figure 102 shows typical connections at the boiler. The

system shown uses a condensate (receiver) tank and pump.

Condensate returns must be properly pitched for gravity

condensate flow and properly insulated so heat contained in

the condensate is not wasted.

The float and thermostatic trap (Fig. 104) can handle large

amounts of air and condensate and is commonly used on steam

coils in air handling systems. In this trap, the thermostatic

element passes air until it senses steam at which time it closes

the valve. As condensate water builds up in the trap, the float

valve opens to discharge condensate into the return line.

Fig. 102. Typical Boiler Connections.

STEAM TRAPS

Traps remove condensate from the steam mains and all steam-

using equipment without allowing steam to enter the return

mains. The thermostatic trap (Fig. 103) is most common for

trapping condensate from radiators and convectors in low

pressure systems. When the thermostatic element senses steam

temperature, it closes the valve. The valve remains closed until

the element cools.

{

BOILER

BLOWDOWN

VALVE

LOW WATER

CUTOFF, PUMP

CONTROL AND

GAUGE GLASS

TO

RECEIVER

TANK

STEAM

PRESSURE

GAUGE

PRESSURE

CONTROLS

F & T

TRAP

STEAM

MAIN

STOP

VALVE

RELIEF

VALVE

F & T

TRAP

HIGH LEVEL

"SPILL"

CONDENSATE

RETURNS

RECEIVER

TANK

PUMP

CHECK

VALVE

SOLENOID

VALVE

(OPTIONAL)

STOP

VALVE

C2923

Reprinted by permission from the ASHRAE Handbook—

1996 Systems and Equipment

Fig. 103. Thermostatic Trap.

THERMOSTATIC

ELEMENT

VALVE

OUTLET

INLET

M15070

Reprinted by permission from the ASHRAE Handbook—

1996 Systems and Equipment

Fig. 104. Float and Thermostatic Trap.

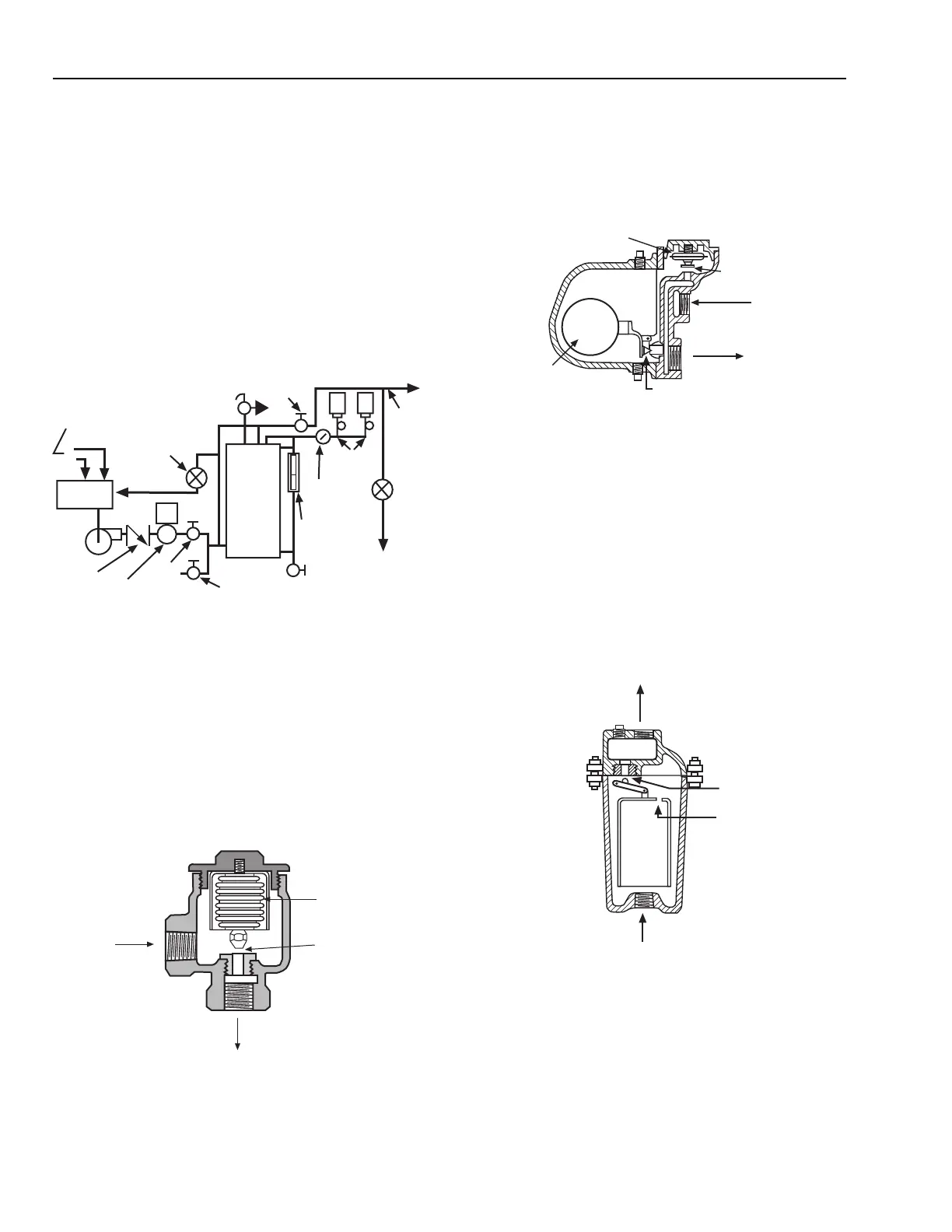

Another common trap is the inverted bucket (Fig. 105) which

has a large capacity (up to 7 kg/s) for discharging condensate.

In the bucket trap, the bucket is normally down so the valve is

open. The bucket is normally about two-thirds full of condensate

so, when condensate enters the trap, it flows around the bucket

and through the trap. As air or steam enters the bucket, the

bucket rises, closing the valve when the condensate level drops

to about one-third full. Air escapes slowly through the air vent

and steam condenses so the bucket drops, opening the outlet.

THERMOSTATIC

DISC ELEMENT

FLOAT

VALVE AND

ORIFICE

VALVE

INLET

OULET

FLOAT

M15071

Reprinted by permission from the ASHRAE Handbook—

1996 Systems and Equipment

Fig. 105. Inverted Bucket Trap.

Kinetic traps, shown in Figures 106, 107, and 108, are used

in high pressure systems. They rely on flow characteristics of

steam and condensate and on the fact that condensate

discharging to a lower pressure contains more heat than

necessary to maintain its liquid state.

OUTLET

VALVE AND

ORIFICE

AIR

INLET

M15072

Loading...

Loading...