INDIVIDUAL ROOM CONTROL APPLICATIONS

ENGINEERING MANUAL OF AUTOMATIC CONTROL

407

The dotted line of F igur e 10 shows a modif ication of this str ategy

wher ein the constant v olume r equir ement is r elaxed a little to

pr ovide some VAV cooling contr ol pr ior to g oing into the hea ting/

mixing por tion of contr ol. This allows a dead band and a little

VAV cooling contr ol. This uses the same har dwar e (and cost) and

allows an easil y adjusta ble minim um airf low, up to the maxim um.

In this conf igur ation, the r oom will oper ate at the hea ting setpoint

most of the time and the lo wer the minim um airf low is set, the

more time control will be in the deadband range or at the cooling

setpoint. Rooms ma y have either high minim um airf low setpoints

or low minim um airf low setpoints.

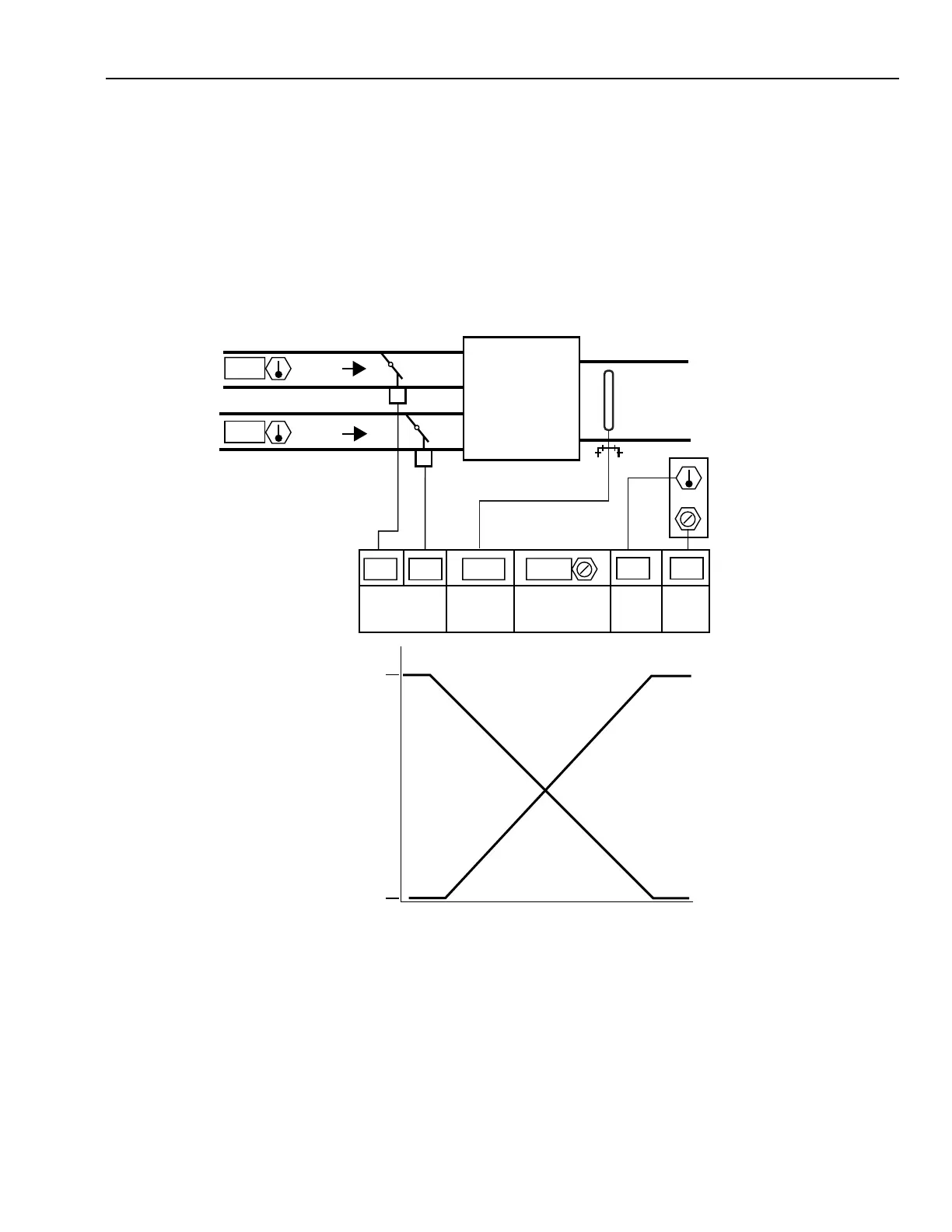

Dual Duct Pressure Independent

Constant Volume ATU

Figur e 11 shows a constant v olume pr essur e inde pendent dual

duct ATU. Modula ting the hot duct damper , up to a total f low

not to exceed the maximum airflow setpoint maintains the room

temper atur e. A constant total airf low is nor mally maintained

by modula ting the cold duct damper . With this conf igur ation,

there is no deadband and comfort is maintained by mixing hot

and cold air a t a constant total airf low. Hot and cold duct

temper atur e load r eset is very impor tant in all dual duct systems

to minimiz e ener gy waste.

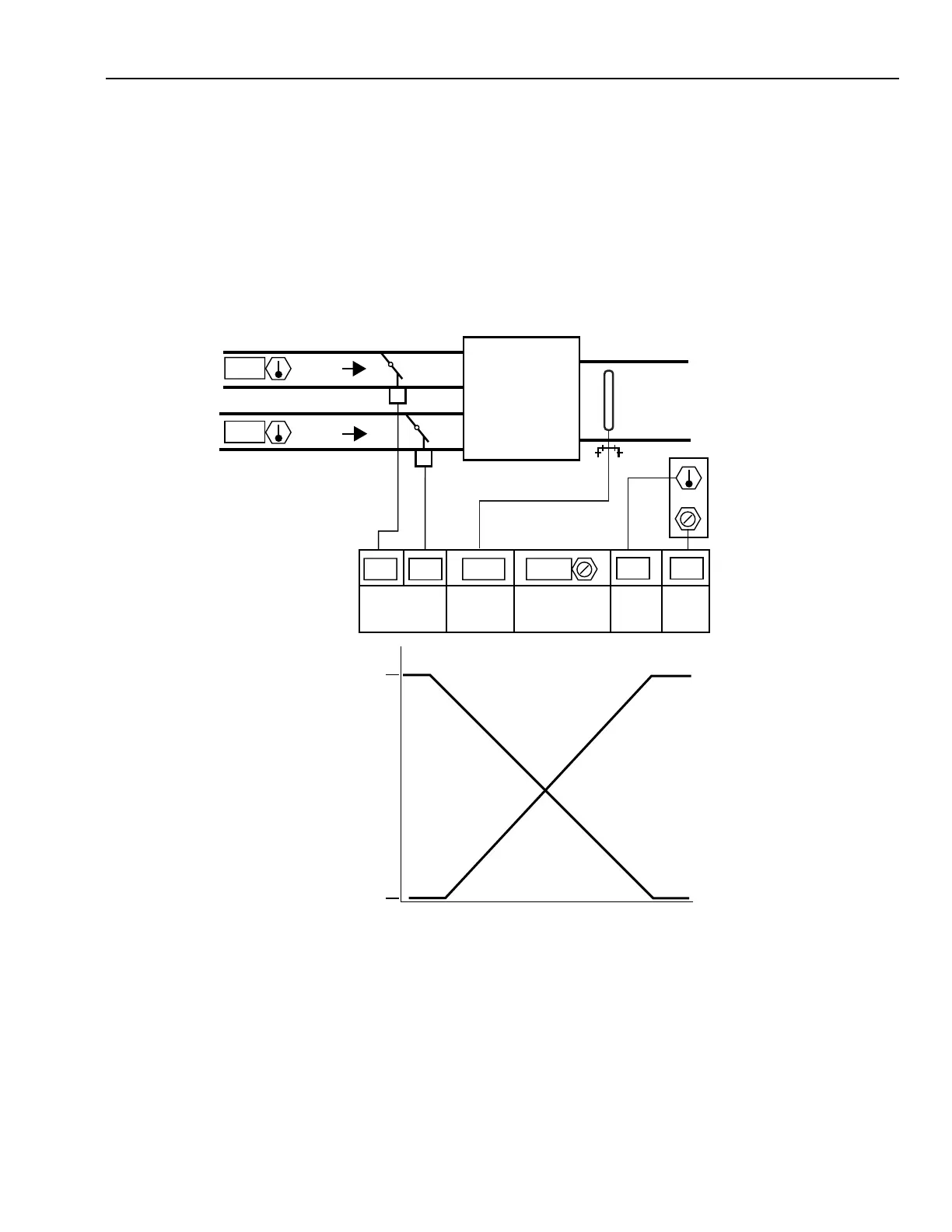

Fig. 11. Dual-Duct Constant Volume Air Terminal Unit.

MAX

HEATING

LOAD

M15312

MAX

COOLING

LOAD

ZERO

AIRFLOW

(m

3

/s)

CONSTANT

AIRFLOW

SETPOINT

HOT DUCT

AIRFLOW

COLD DUCT

AIRFLOW

24 24

13

25.5

0.4550.45500 77

AIRFLOW

SETPOINT

(m

3

/s)

CURRENT

AIRFLOW

(m

3

/s)

DAMPER

PERCENT

OPEN

COOLING

SETPOINT

TEMPERATURE

WALL MODULE

HOT

DUCT

COLD

DUCT

Loading...

Loading...