ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

384

KEY POINTS

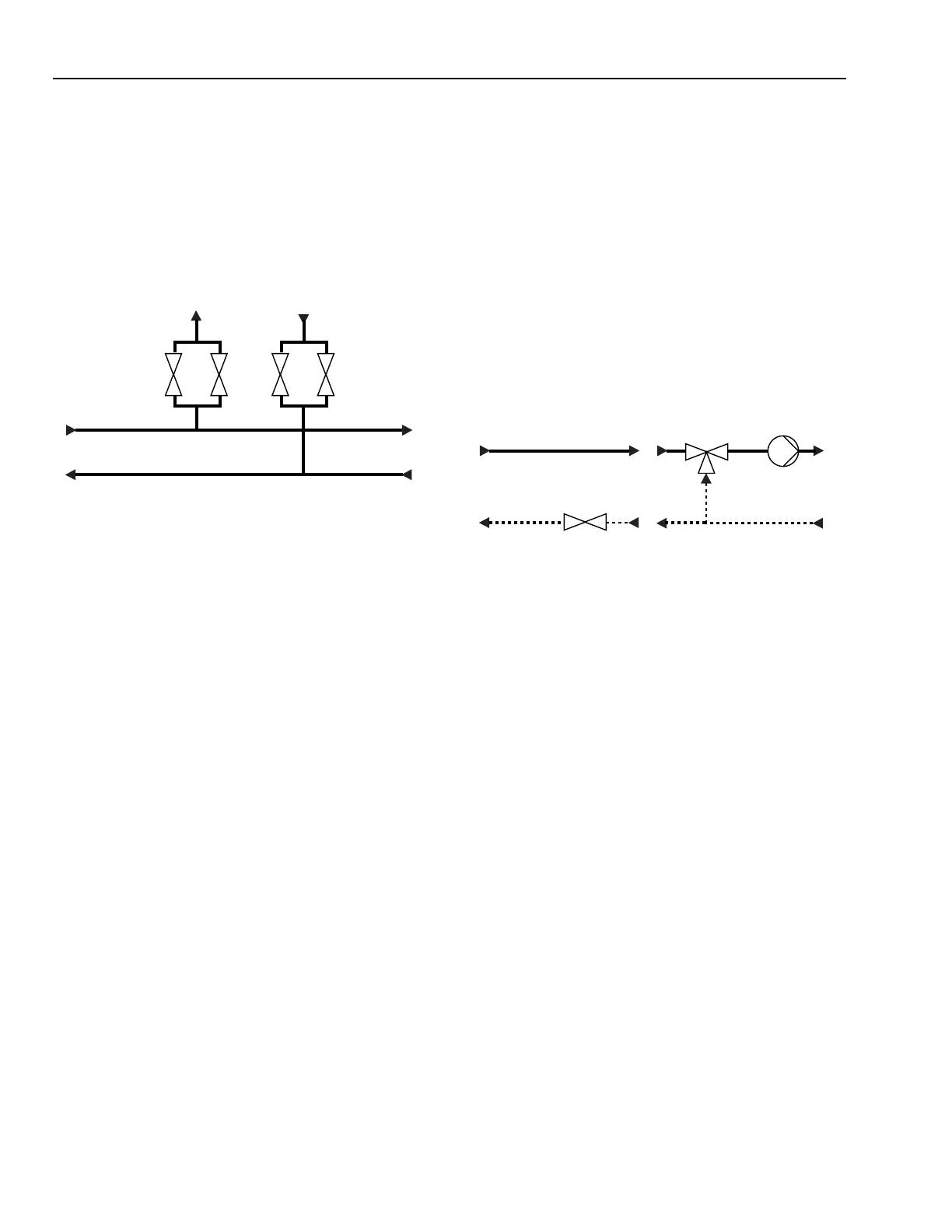

Key points are locations where pipelines branch off (Fig. 129).

They consist of valves for supply and return flow which can

separate the branch line from the main line. If a branch line is

shut down, the pressure ratio in the entire network is affected.

To prevent pressure spikes in the main system, the shutdown

must be performed slowly and carefully. Often two different

sized surge tanks in parallel are used to damp the pressure peak

during shutdown. Usually key point temperatures and pressures

are monitored.

Functional principles:

The primary side consists of the supply and return lines, plus

necessary pressure reducing, regulating, and safety equipment.

This is self-regulating equipment which provides a given

differential pressure, absolute pressure reducing, and safety

close off functions.

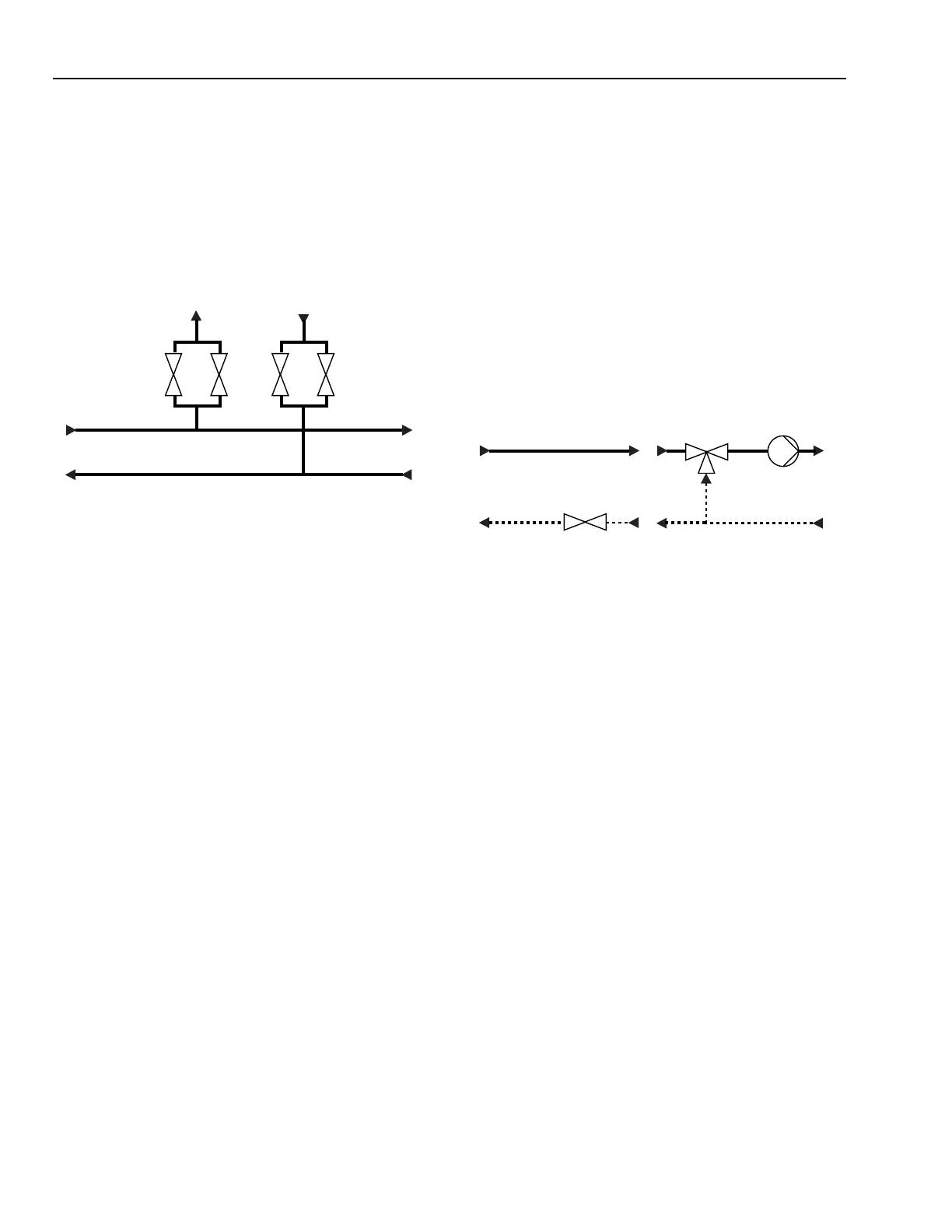

The heat regulation unit (Fig. 130) provides the required

temperature by controlling the primary flow (A) or by mixing

the cooled return water with supply water (B). Different

configurations with two and three way valves can be used. In

the flow control configuration a fixed speed circulating pump

increases the pressure in the return line above the supply flow

pressure. In the temperature control configuration either a jet

pump or a three way valve is used.

Fig. 129. Typical Key Point.

HEAT TRANSFER SUBSTATIONS

In general heat transfer substations link district heating

networks with the consumer. The consumer side can be either

another network or the end user.

Heat transfer can be either direct and indirect. Direct transfer

uses mixing valves, jet pumps or two way valves to supply the

heating medium directly to the consumer. Indirect substations

use heat exchangers and physically decoupled or independent

heating circuits.

Direct Heat Transfer Substations

The main parts of a direct substation are:

– Primary side.

– Heat flow regulation unit.

– Circulating pumps.

– Secondary side.

Direct heat transfer substations:

– Transfer the required heat from the supply (primary) side

to the consumer (secondary) side.

– Meter heat.

– Provide safety functions to protect consumer and

equipment against overheating, frost, and harmful agents

in hot tap water.

– Provide optimization functions to reduce energy

consumption to the lowest possible level.

Fig. 130. Two- And Three-Way Valve

Configurations for a Heat regulation Unit.

Jet pumps use the effect of injection, making a mechanical

pump unnecessary, thereby, saving electrical energy. However,

adapting and dimensioning jet pump applications to fit operating

conditions is difficult.

Control loops used in a direct substation:

– Supply flow temperature reset on outdoor air temperature.

– Return temperature limit.

– Time schedule functions.

– Night setback and frost protection.

Small Substation For Multiple Family Buildings

Figure 131 shows a typical direct heat transfer substation.

M11445

RETURN FLOW

SUPPLY FLOW

MAIN LINES

BRANCH

SURGE

TANKS

M11446

CONTROL VALVE

CIRCULATING

PUMP

THREE-WAY

MIXING VALVE

OR JET PUMP

A) FLOW CONTROL

B) TEMPERATURE CONTROL

SUPPLY LINE

RETURN LINE

Loading...

Loading...