ENGINEERING MANUAL OF AUTOMATIC CONTROL

AIR HANDLING SYSTEM CONTROL APPLICATIONS

238

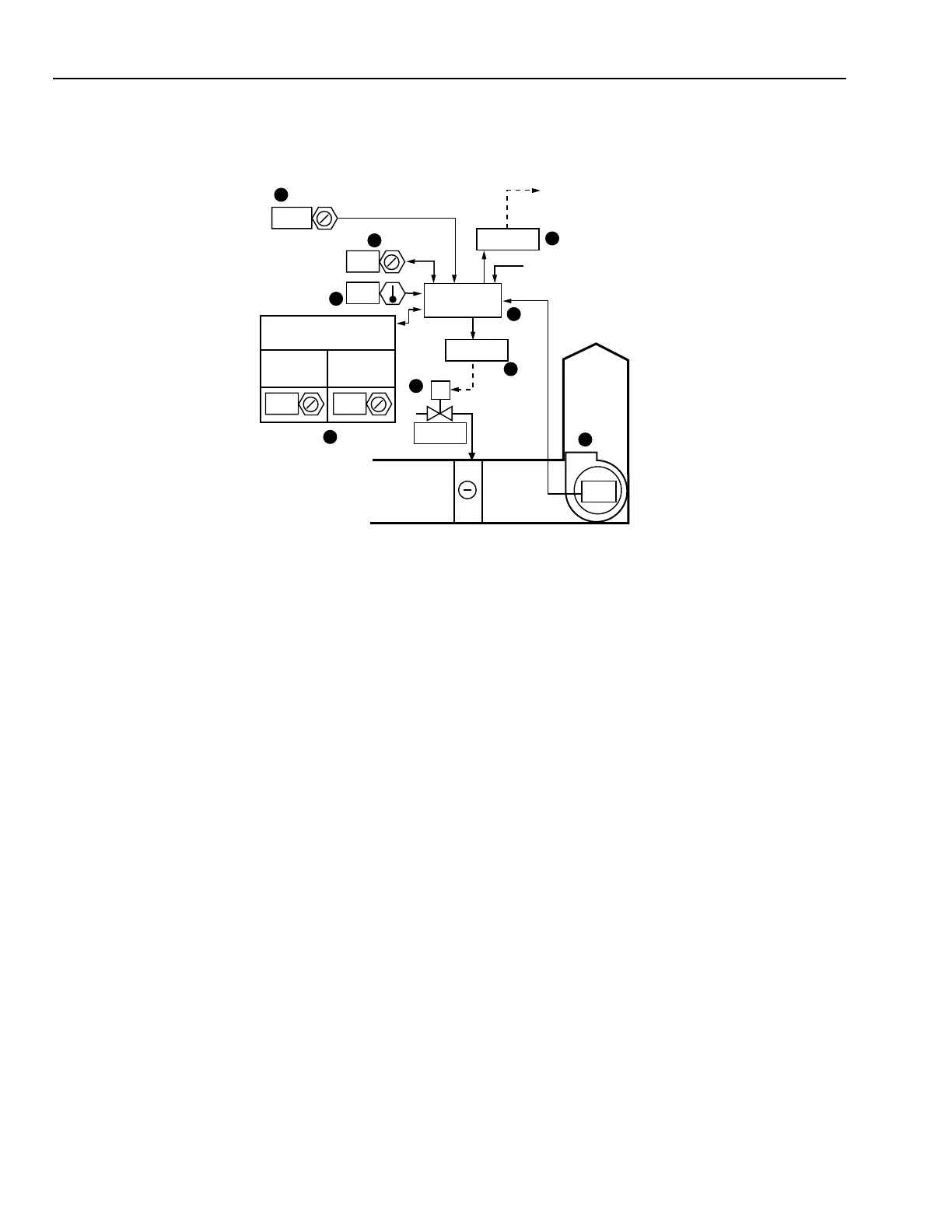

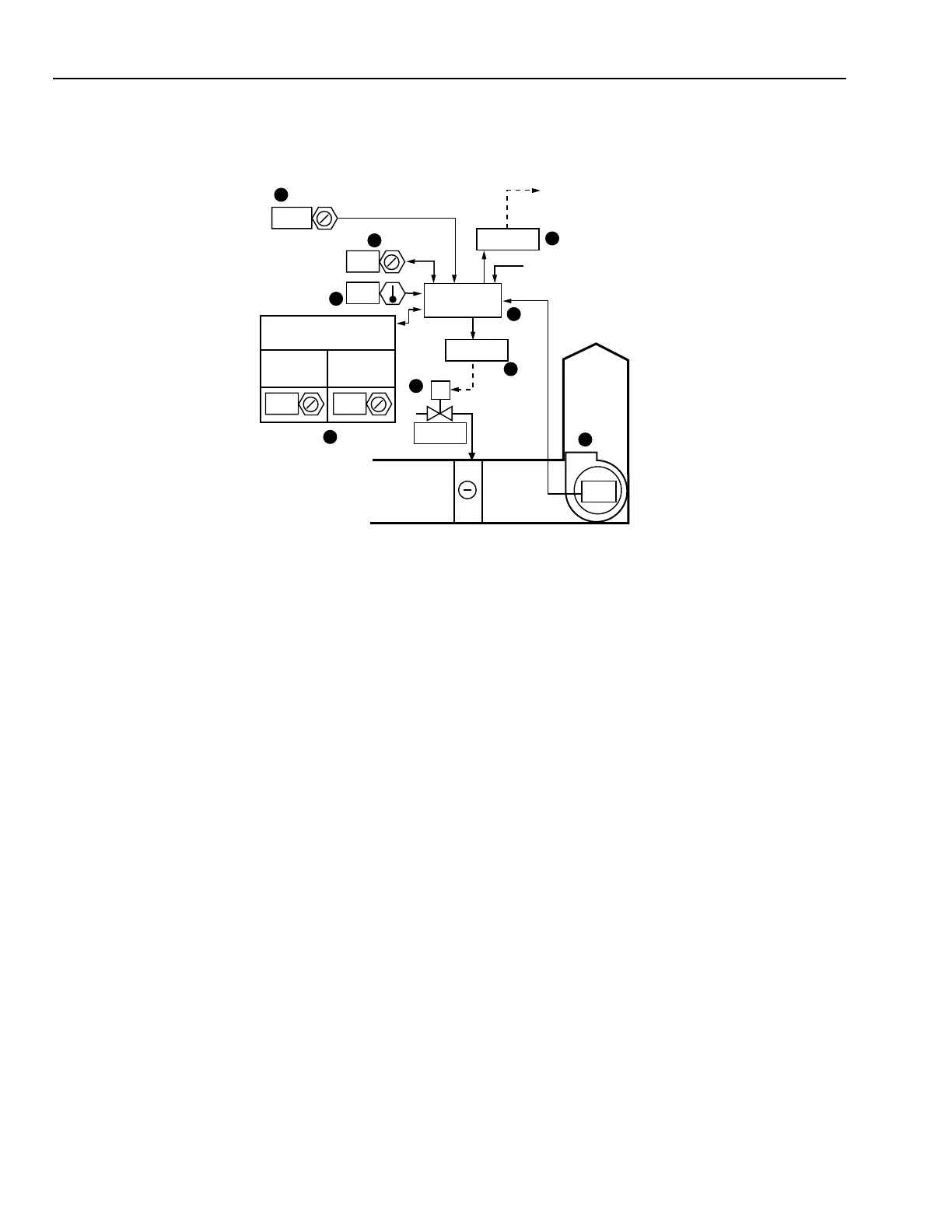

Item

No. Function

1 Control system energizes when fan is turned

on (See FAN SYSTEM START-STOP

CONTROL).

2 Space temperature inputs to control program.

3 Setpoint determines refrigerant on mode.

4 Refrigerant solenoid valve closes when fan is off.

5 Relay controls liquid line solenoid valve.

6 Relay enables compressor start control system.

7 Temperature differential determines

compressor off mode.

8 Compressor minimum on and minimum off

times prevent short cycling.

9 Control program coordinates cooling, safety,

and fan interlock control.

FEATURES

1. The refrigerant liquid line solenoid valve is closed and the

compressor cannot be energized when the supply fan is off.

2. Software time delays for compressor protection.

CONDITIONS FOR SUCCESSFUL OPERATION

The differential timers are set wide enough and the software

timers are set high enough to prevent short cycling of the

compressor under light load.

LIMITATIONS

1. Direct expansion coils are difficult to control from leaving

air due to the large and rapid temperature drop when

energized.

2. Compressor operating and safety controls must be

incorporated into the control system.

SPECIFICATIONS

See FAN SYSTEM START-STOP CONTROL.

The DX control system shall be enabled anytime the fan

operates.

Cooling system shall be cycled by a temperature control loop

with a 1.4 kelvins (adjustable) differential to maintain the space

temperature setpoint. When the system is commanded on by

the control program, it shall remain on at least eight minutes,

and when it is commanded off (or drops off during power

interruptions) it shall remain off at least ten minutes.

On a rise in space temperature to the setpoint, the refrigerant

liquid line valve shall open and a relay shall enable the

compressor to start under it’s controls.

When the space temperature drops to a value equal to the

space temperature setpoint minus a differential, the liquid line

solenoid valve shall close, and the compressor shall continue

to operate until shut down by it’s low-pressure cutout.

Refrigerant system control and interlock wiring shall be as

recommended by the compressor manufacturer.

TWO-POSITION CONTROL OF DIRECT EXPANSION COIL SYSTEM

Functional Description

M15170

4

MA

SA

ON

1

8

8

10

MINIMUM

ON TIME

MINIMUM

OFF TIME

COMPRESSOR

(MINUTES)

6

9

5

RELAY

RELAY

OPEN

CONTROL

PROGRAM

3

7

2

24.5

1.4

24.5

SUPPLY

FAN

TEMPERATURE

CONTROL

DIFFERENTIAL

(KELVINS)

TO

COMPRESSOR

START

CIRCUIT

COMPRESSOR

VOLTAGE MONITOR

Loading...

Loading...