ENGINEERING MANUAL OF AUTOMATIC CONTROL

CHILLER, BOILER, AND DISTRIBUTION SYSTEM CONTROL APPLICATIONS

343

Table 4. Variable Speed Pump relationships

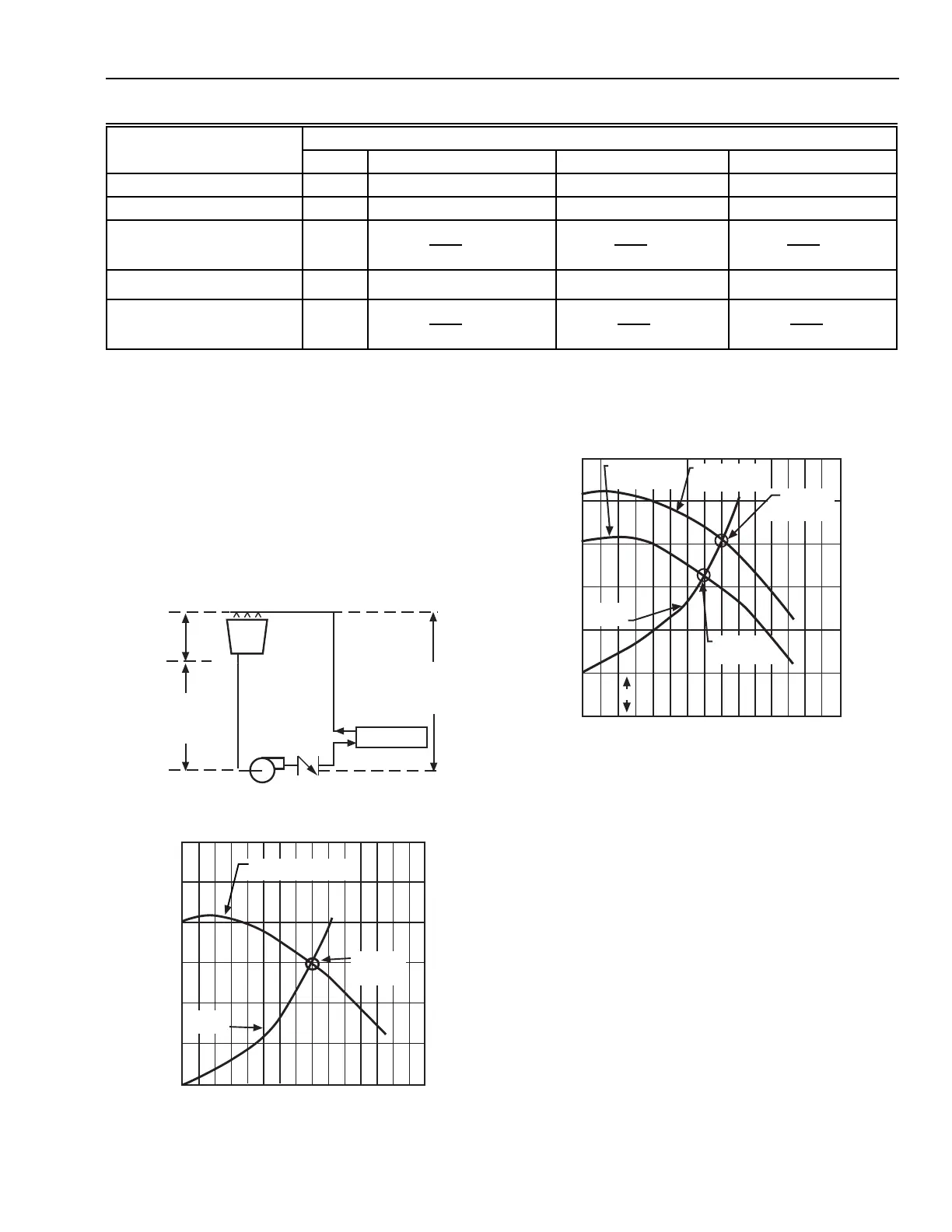

Figure 64 shows the system curve adjusted for the 30 kPa of

static pressure and the actual operating points of Pump A

(selected in Figure 63) and Pump B. Notice Pump A supplies

only 10.5 L/s at 125 kPa.

PUMPS APPLIED TO OPEN SYSTEMS

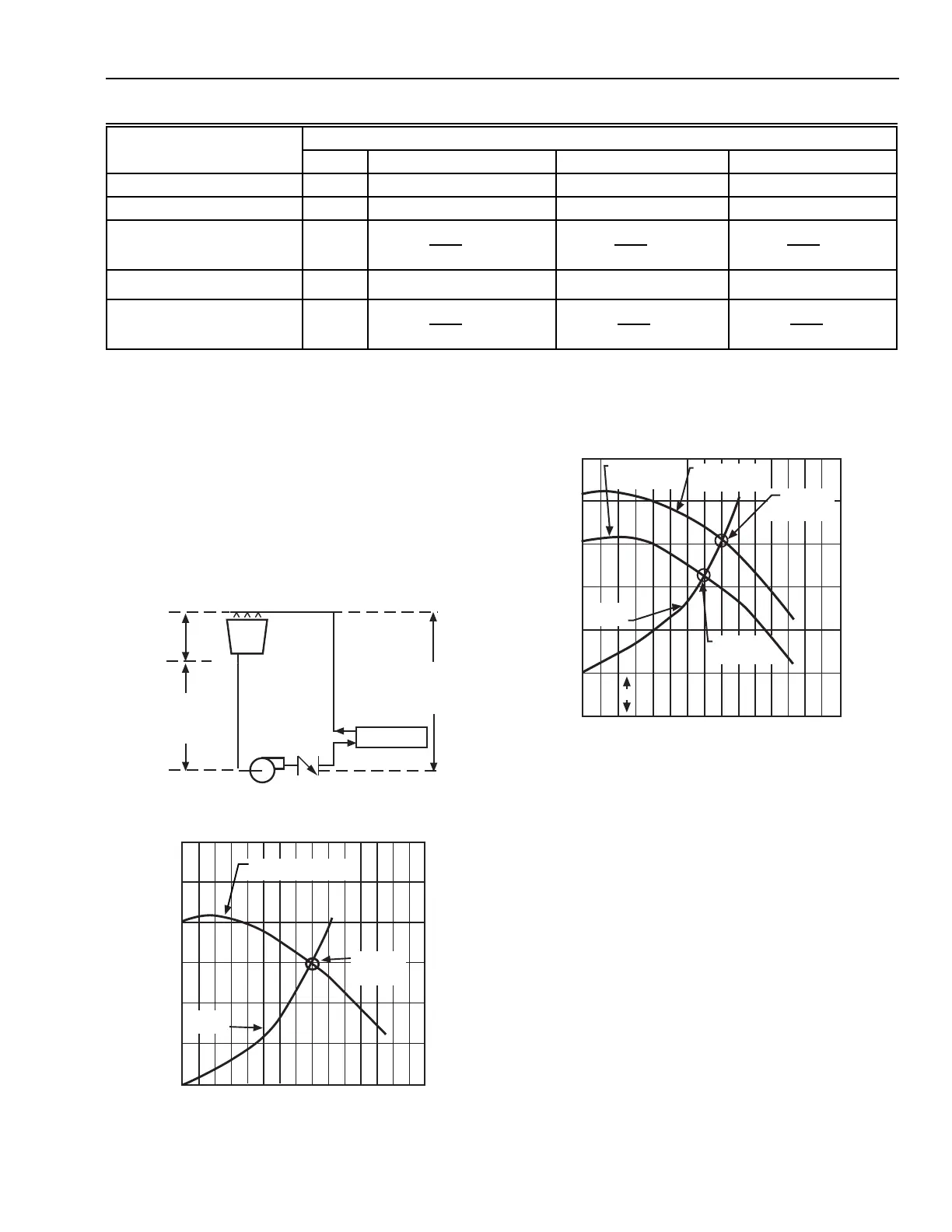

In cooling towers (Fig. 62) and other open systems, static

pressure must be considered when establishing system curves

and selecting a pump. Notice that the 27m of vertical pipe

(270 kPa static discharge pressure) is partially offset by the

24m of vertical pipe (240 kPa static suction pressure) in the

suction line. When a system curve is drawn for such a system,

static pressure of the tower must be added to the system curve.

The system is designed to operate at 12 L/s against 90 kPa for

piping and valves. The system curve in Figure 63 is drawn

through zero pressure (ignoring the 3m or 30 kPa static

pressure) which leads to choosing Pump A.

Fig. 62. Typical Cooling Tower Application.

Fig. 63. System Curve for Open

Circuit without Static Pressure.

Fig. 64. System Curve for Open

Circuit with Static Pressure.

MULTIPLE PUMPS

Multiple pumps are used when light load conditions could

overload a single pump. These conditions normally occur when

two-way control valves are used in the control system. Two-

way control valves sharply reduce flow when they begin to

close. Figure 65 shows that in a single-pump system, over

pressure can result at low flow. At one-third flow, the pump

pressure has increased, the source and piping drop is reduced

to one-ninth of the design drop, and the control valve drop has

increased greatly. Bypass, variable speed, or throttling valve

pressure relief should be used with a single pump. Where the

heat exchanger (such as a chiller) requires a high minimum

flow rate, a single pump is used, and diversity is not used, three-

way load control valves should generally be used.

CONDENSER

12 L/s

COOLING

TOWER

27m

STATIC

DISCHARGE

PRESSURE

(270 kPa)

3m

TOTAL

STATIC

PRESSURE

(30 kPa)

24m

STATIC

SUCTION

PRESSURE

(240 kPa)

C4096

FLOW IN L/s

TOTAL PRESSURE (kPa)

180

150

120

90

60

30

0

3

6

9

12

15

18

21

C4097

PUMP A

PERFORMANCE CURVE

SYSTEM

CURVE

INDICATED

OPERATING

POINT

180

150

120

90

60

30

0

3

6

9

12

15

18

21

FLOW IN L/s

TOTAL PRESSURE (kPa)

30

C4098

ACTUAL

OPERATING

POINT PUMP B

PUMP B

PERFORMANCE

CURVE

PUMP A

PERFORMANCE

CURVE

SYSTEM

CURVE

ACTUAL

OPERATING

POINT PUMP A

Load (percent)

Condition 100 80 60 40

Flow (L/s) 31.5 0.80 x 31.5 = 25.2 0.60 x 31.5 = 18.9 0.40 x 31.5 = 12.6

Speed (rpm) 1750 0.80 x 1750 = 1400 0.60 x 1750 = 1050 0.40 x 1750 = 700

Total Pressure (kPa) 210

210 x

()

1400

1750

2

= 134.4 210 x

()

1050

1750

2

= 75.6 210 x

()

700

1750

2

= 33.6

Fully Open Valve Drop (kPa) 30

30 x 0.80

2

= 19.4 30 x 0.60

2

= 10.8 30 x 0.40

2

= 4.8

Motor Power (kW) 10.1

10.1 x

()

1400

1750

3

= 5.17 10.1 x

()

1400

1750

3

= 2.18 10.1 x

()

1400

1750

3

= 0.65

Loading...

Loading...