Alarm Handling - List of all alarms

Part No.: 4418309_Rev09 Fusion4 MSC-L

Honeywell Installation & Operation Manual 6 - 15

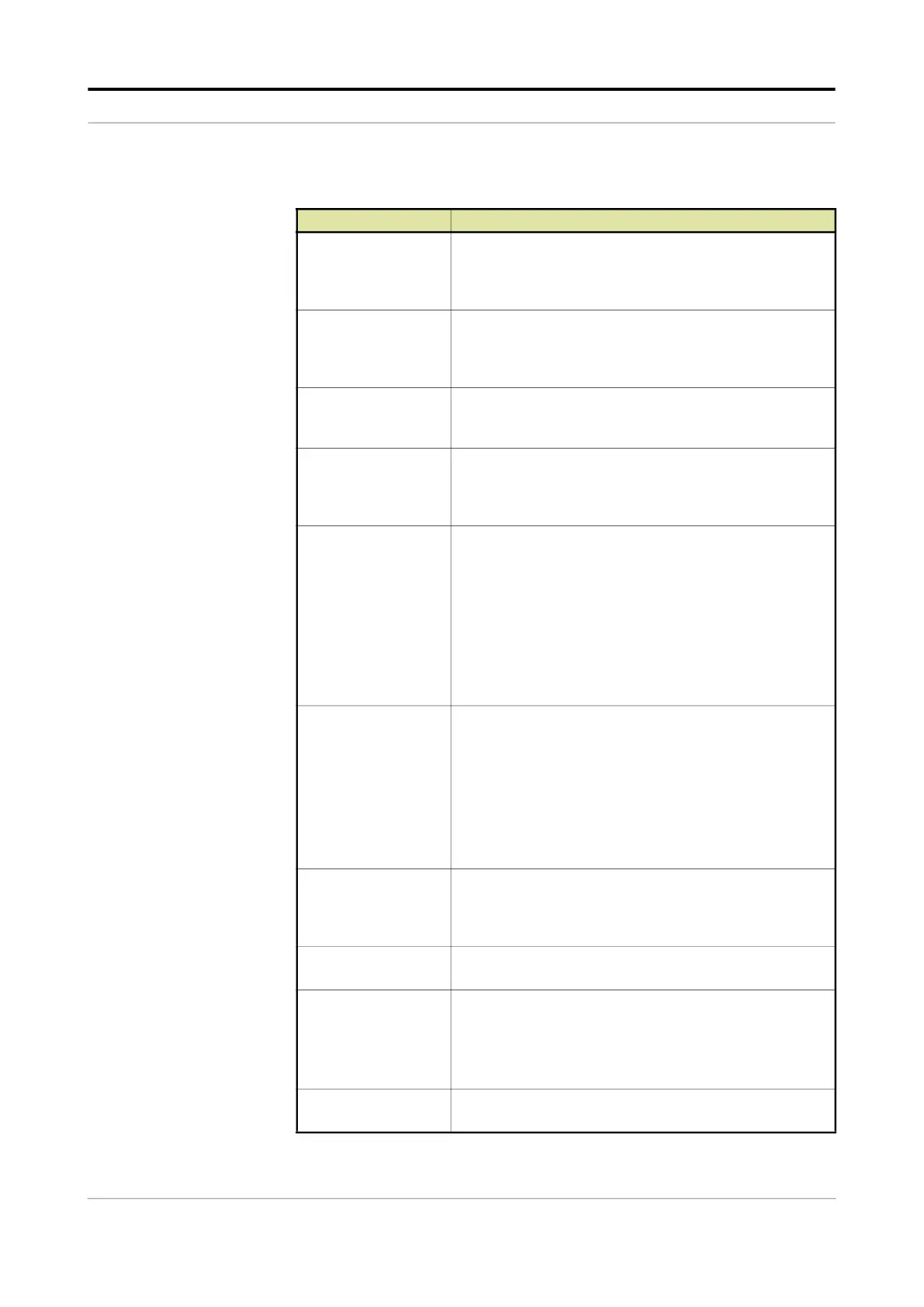

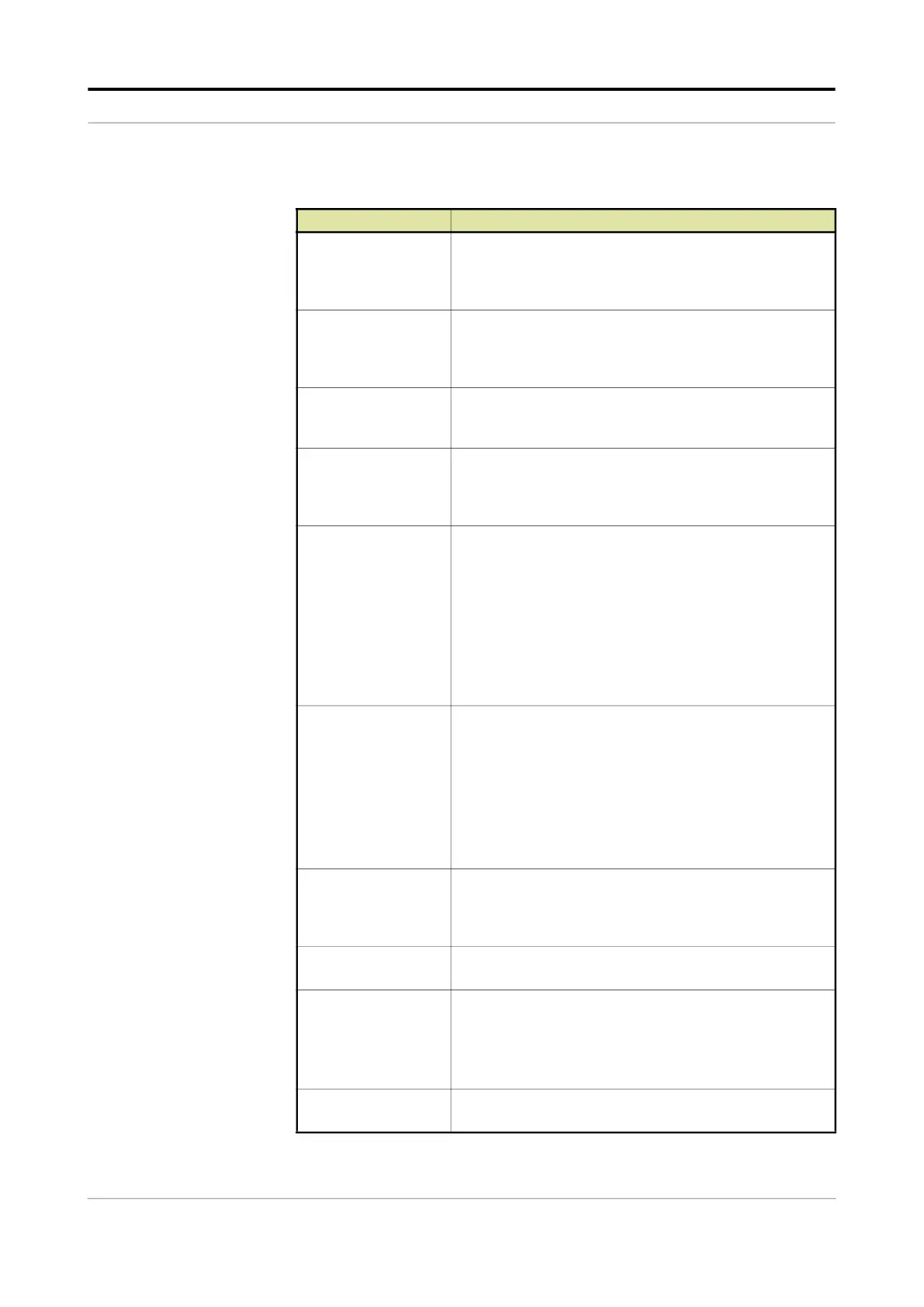

6.8.5 Additive Stream Alarms

Alarm Cause

Leaking valve Volume accumulated on the additive stream meter within

the

[leaking timeout period] is more than the [leaking

Volume limit] (when the stream is idle or in between

injections.)

No additive The

[number of retries] * [no additive timeout] is elapsed

after the additive pulses stop during a batch.

As soon as the additive solenoid opens, the timer

[no

additive timeout] starts.

No pump The pump feedback signal is not detected within the

[pump

feedback timeout]. It is only possible if the I/O binding for the

pump is ON/OFF and the pump indications are configured.

Block valve fault The block valve feedback signal is not detected within the

[block valve feedback timeout].

It is only possible if the I/O binding for the block valve is ON/

OFF and the block valve indications are configured.

Low volume deviation The average of the additive injection volume calculated over

the configured number of cycles is lower than the additive

deviation percentage. The

alarm is evaluated after every injection.

With the entity

[Additive volume deviation], the acceptable

deviation can be set.

With the entity

[Number of cycles before deviation alarm

evaluation], the number of additive injection cycles that are

used for calculating the average of the injection volume for

the deviation calculations can be set.

High volume deviation The average of the additive injection volume calculated over

configured number of cycles exceeds the additive deviation

percentage. The alarm is evaluated after every injection.

With the entity

[Additive volume deviation], the acceptable

deviation can be set.

With the entity

[Number of cycles before deviation alarm

evaluation]

, the number of additive injection cycles that are

used for calculating the average of the injection volume for

the deviation calculations can be set.

Control fault The MSC-L is not configured appropriately and does not

have sufficient time to handle all the inject triggers.

NOTE: The maximum number of triggers that can be stored

inside the buffer is 10.

Solenoid fault The system cannot activate or deactivate the solenoid. (This

is an internal firmware control failure).

Pulse hardware fault The pulse input module detects the following error

conditions.

• Reading information from the Pulse Input processor.

• Pulse overflow errors.

• BAD health of the pulse input function.

Pulse phase fault The dual pulse input are out of phase.

It is only possible if the MSC-L is configured for quad pulse.

Loading...

Loading...